The linear vibrating screen machine, as a critical piece of equipment within masterbatch production lines, efficiently accomplishes the screening, grading, and impurity removal of granules, ensuring each batch of masterbatch exhibits consistent particle size and freedom from contaminants.

Through the precise screening capabilities of the linear vibrating screen machine, manufacturers can not only enhance product quality and consistency but also achieve higher production efficiency and lower defect rates. Here we learn about the application and advantages of linear vibrating screen in the masterbatch industry and the common models and specifications of linear vibrating screen.

What is linear vibrating screen?

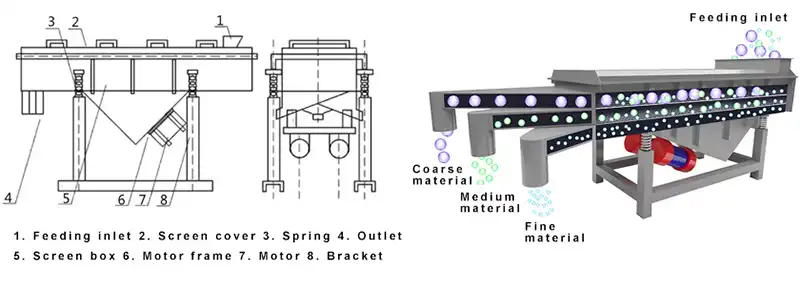

Linear vibrating screen machine is a kind of screening equipment that uses vibrating motor to generate excitation force to make materials do linear motion on the screen surface. It can be equipped with single or multi-layer screen mesh to achieve the functions of classification, debris removal, dust removal, detection, washing, dewatering, cleaning raw materials, and separation of iron in materials.

Stainless Steel

Stainless Steel Stainless Steel

Stainless Steel Carbon Steel

Carbon Steel Carbon Steel

Carbon Steel

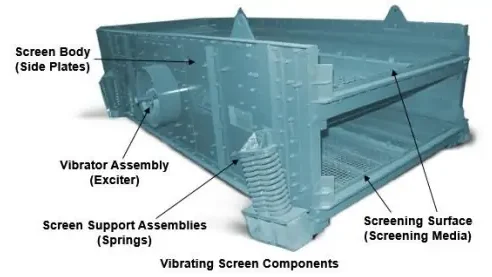

Linear Vibrating Screen Parts

The structure of a linear vibrating screen is relatively simple, typically comprising the screen body, screen mesh, vibration motor, and support structure.

Screen Body:The main body of the vibrating screen that holds the material, connecting the feed inlet and discharge outlet. It is generally constructed using horizontal tubular beams or channel beams, heavy-duty angle steel, and flat beams, secured with a bolted structure.

Screen Mesh:The vibrating screen mesh is usually made of 304 stainless steel, formed by interweaving steel wires to filter materials.

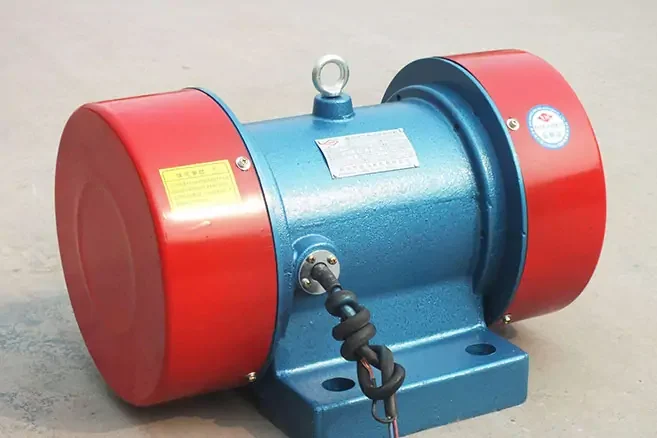

Vibration Motor:Linear vibrating screens typically feature two vibration motors. These motors generate excitation force through the rotation of their own eccentric weights, driving the screen body and mesh to perform linear vibration.

Supporting structure:Composed of components made from springs and rubber materials, this structure supports the entire equipment while absorbing vibrations. It reduces ground impact and equipment sway, ensuring smooth operation of the linear vibrating screen and minimizing noise.

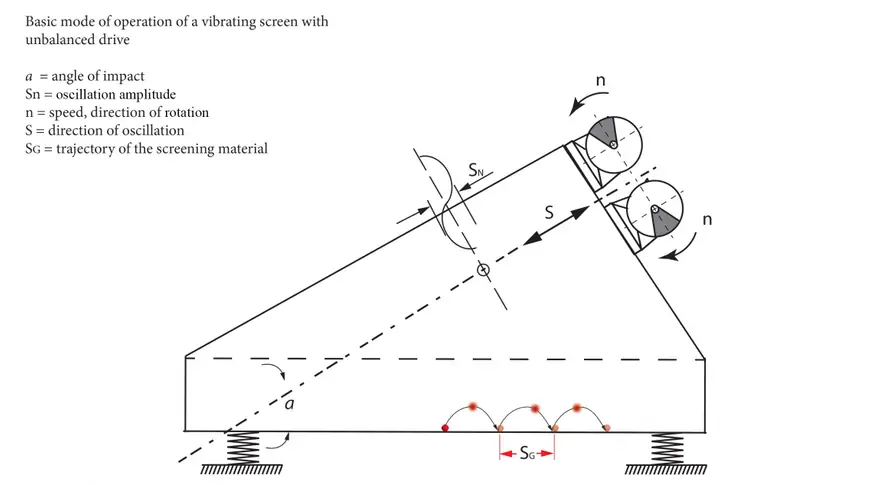

Working Principle

Linear Vibrating Screen rotates in reverse synchronously through two vibrating motors, generating linear vibration force, which makes the materials make jumping and linear forward movement on the vibrating screen surface. Qualified particles pass through the screen mesh, and unqualified materials are separated, so as to achieve accurate screening.

Four Key Applications of Linear Vibrating Screens in the Masterbatch Industry

Raw material screening and removal of impurities

Linear vibrating screens are commonly used in the pre-treatment stage of raw materials to remove lumps, foreign materials and large particles (such as metal chips, fibres, etc.) in materials such as resins, pigments and additives. By adjusting the mesh size (usually 80-300 mesh), the purity of the raw material can be improved, reducing problems in the later stages of remixing and extrusion. For example, pigments can be screened to reduce colour differences, resins can be screened to prevent uneven melting, etc. thus improving the quality and efficiency of the masterbatch.

Finished product grading and screening

After the finished masterbatch particles may have differences in particle size, linear vibrating screen through multi-layer screen (such as 20 mesh, 40 mesh, 60 mesh combination) for accurate grading, in line with the customer-specified range of particles to meet the look at the particle size requirements of different customers. In this link, the linear sieving machine enhances the uniformity of the products of colour masterbatches and meets the downstream processing requirements.

Remove unqualified particles

In the production process, over-sized or under-sized particles may be generated due to extrusion temperature, cutting process and other factors. The linear vibrating screen can efficiently screen out these rejects. Unqualified particles can be recycled and re-pelletised, reducing the waste of raw materials and improving the yield.

Enhance production efficiency and automation

Linear vibrating screen has the characteristics of high processing capacity and low energy consumption, which is suitable for large-scale continuous production. Its fully enclosed structure reduces dust spillage and meets the requirements of environmental protection; automated screening reduces manual intervention and lowers production costs. The modular design supports rapid screen replacement (e.g. 40 mesh to 80 mesh), adapting to the needs of different formulations.

Advantages of linear vibrating screen

- Compact and durable design, easy to operate.

- Easy to clean and change the screen.

- Automatically discharging impurities and coarse material, realising automatic operation.

- All stainless steel structure, ensure the purity of materials.

- Fewer faults, easy maintenance.

- light weight, the base is equipped with casters, easy to move and place.

- In addition to standard configuration, customised mesh size is also available.

Common Linear Vibrating Screen Models and Specifications Overview

| Model | SYZ-520 | SYZ-525 | SYZ-530 | SYZ-1020 | SYZ-1025 | SYZ-1030 | SYZ-1225 |

|---|---|---|---|---|---|---|---|

| Dimension (mm) | 500×2000 | 500×2500 | 500×3000 | 1000×2000 | 1000×2500 | 1000×3000 | 1200×2500 |

| Material diameter (mm) | 0.074-20 | 0.074-20 | 0.074-20 | 0.074-40 | 0.074-40 | 0.074-40 | 0.074-40 |

| Shake frequency(time/min) | 960 | 960 | 960 | 960 | 960 | 960 | 960 |

| Gradient | 1-7 | 1-7 | 1-7 | 1-7 | 1-7 | 1-7 | 1-7 |

| Amplitude | 1-4.5 | 1-4.5 | 1-4.5 | 1-4.5 | 1-4.5 | 1-4.5 | 1-4.5 |

| The layer number | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

| POWER (kw) | 2×(0.37-0.75) | 2×(0.37-0.75) | 2×(0.37-0.75) | 2×(0.75-1.1) | 2×(0.75-1.5) | 2×(0.75-1.5) | 2×(0.75-1.5) |

Conclusion

If you are in the masterbatch industry and are looking for solutions to improve production efficiency and product quality, then choose our vibrating screen products. According to the different links and needs of masterbatch production, we can customise the most suitable vibrating screen models and configurations for you, so that your production capacity can be improved at the next time.

At the same time, we also provide perfect pre-sale consulting, installation and commissioning and after-sales technical support services, so that you have no worries in the process of using our products.

Contact us today to obtain your bespoke linear vibrating screen solution!

FAQ about Linear Vibrating Screen for Masterbatch Industry

Q1. What is the role of a linear vibrating screen in masterbatch production?

A1: A linear vibrating screen is mainly used for grading and impurity removal during masterbatch production. It ensures uniform particle size, removes foreign materials, and improves the overall quality and consistency of the masterbatch.

Q2. Why is particle size uniformity important for masterbatch?

A2: Uniform particle size directly affects the dispersion, color stability, and surface quality of plastic products. Using a linear vibrating screen helps maintain consistent granule size, ensuring stable color and performance.

Q3. Can a linear vibrating screen handle different types of masterbatch materials?

A3: Yes. It can be used for color masterbatch, additive masterbatch, and filler masterbatch. The screen mesh size and vibration parameters can be adjusted according to material properties.

Q4. What are the advantages of using a linear vibrating screen over manual or traditional methods?

A4: It offers higher efficiency, consistent precision, lower labor cost, and continuous operation. This ensures higher output and improved product quality.

Q5. How to choose the right linear vibrating screen for masterbatch production?

A5: Consider factors such as production capacity, particle size range, material type, and required cleanliness. For the best results, consult professional engineers for customized solutions.