Customize Sand Making Production Line System

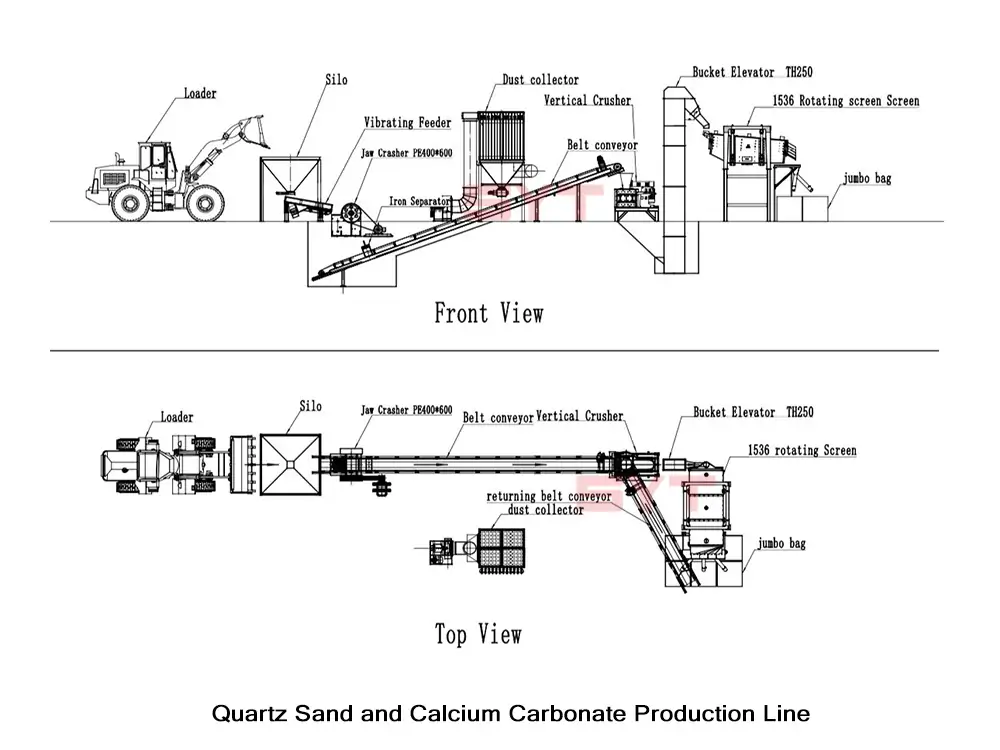

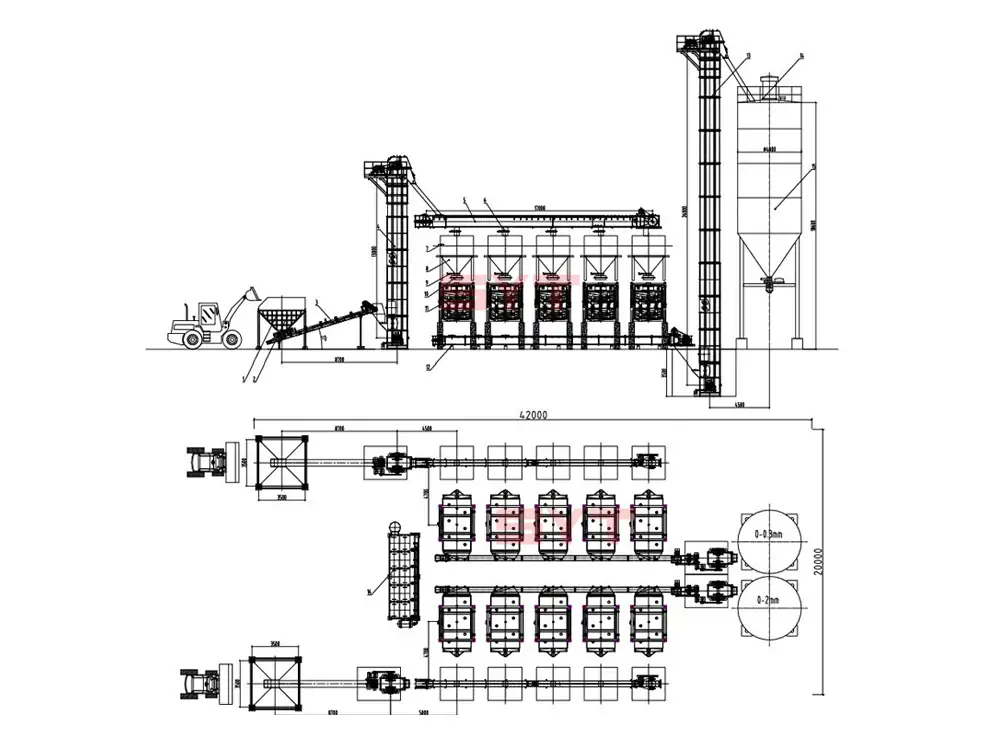

The sand making production line includes jaw crusher or impact crusher, sand conveyor belt, bucket vertical elevator, large-capacity square gyratory screen, and large-capacity storage silo.

The system has the characteristics of large processing capacity, precise grading, high automation, energy saving and environmental protection. It can realize fine screening of raw materials from 2 mesh to 150 mesh, with a processing capacity of up to 30 tons/hour, which is perfectly adapted to the fine grading needs of the sand and gravel industry.

sand Making production line System equipment composition

Sand making production line mainly consists of crusher, belt conveyor, bucket elevator, vibrating screen, silo and so on. According to the demand of production process, it may also be equipped with dust removal equipment, coarse and fine powder separator and other auxiliary equipment.

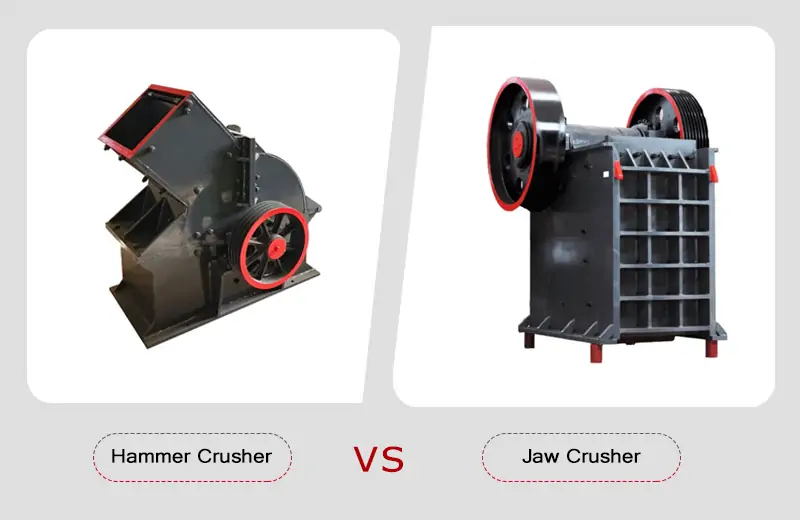

- Crusher: Crushing large dry sand raw materials into small particles suitable for subsequent processing. High crushing efficiency, large crushing ratio, can handle materials of various hardness.

- Sand Conveyor Belt: Conveying the crushed sand from the crusher to other equipment, such as a bucket elevator or silo. Large conveying capacity, long conveying distance, smooth and reliable operation.

- Bucket Elevator: Lift the sand from a low to a high place to enter the silo or further processing equipment. Large lifting height, small footprint, high lifting efficiency.

- Vibrating Sand Screening Machine: Screening dry sand, separating dry sand of different granularity to meet different usage requirements. High screening efficiency, high screening precision, and various specifications of screen mesh, which can be adjusted according to the needs.

System Equipment

Sand Making Production line process

The process flow of the sand making production line is as follows:

- Raw material preparation: The raw stone is evenly fed into the jaw crusher through a vibrating feeder for coarse crushing.

- Coarse crushing: The coarsely crushed stone is fed into the cone crusher or impact crusher through a belt conveyor for fine crushing.

- Fine crushing: The finely crushed stone is fed into the impact crusher (sand-making machine) again through a belt conveyor for sand-making.

- Screening: The material after sand making enters the sand screening machine for classification, and the unqualified particle size needs to be returned for reprocessing.

- Finished product output: The sand particles that meet the requirements are output as finished sand through a belt conveyor, and the materials that need to be returned for reprocessing re-enter the sand-making machine for processing.

Quartz Sand and Calcium Carbonate Production Line

Sand Making Production Line

Application materials

It is used to screen dry sand such as fracturing sand, quartz sand, silica sand, mechanism sand, ceramic sand, glass sand, resin sand, and so on.

Silica Sand

Silica Sand Quartz Sand

Quartz Sand Oil Fracturing Proppant

Oil Fracturing Proppant Ceramic Sand

Ceramic Sand Perlite

Perlite Metal Silicon Powder

Metal Silicon Powder Industry Salt

Industry Salt Cork powder

Cork powder Calcium Carbonate

Calcium Carbonate Soda Ash

Soda Ash

Sand Making Production line features

- Large output: the production line adopts high-efficiency screening and conveying equipment, with an output of up to 10-30 tons/hour, which is capable of realizing large output and meeting the demand of large-scale production.

- High production efficiency: the equipment work closely with each other, high production efficiency, to realize the rapid screening and processing of sand materials.

- High screening precision: the square swing screen adopts advanced screening technology with high screening precision, which can meet the requirements of different users for dry sand grain size. The sand grain after screening is full and round, in line with high-quality requirements.

- Strong relevance and easy maintenance: the production line is developed for oil fracturing sand, which is easy to maintain and repair and reduces the cost of use, and the equipment can be configured according to the customer’s production line.

- The high degree of automation: the whole production line adopts an automatic control system, realizing automatic start and stop of equipment, fault alarm remote monitoring, and other functions.

- Stable operation: the screening and conveying equipment has a sturdy structure, smooth operation, and low failure rate, which can run stably for a long time and reduce downtime.

- Environmental protection and energy saving: the production line adopts advanced dust removal and noise reduction technology to reduce dust and noise pollution; at the same time, the equipment has low energy consumption, which meets the requirements of environmental protection and energy saving.

Customer Site Photos Show

We have a good record of successful sand production line projects and can provide detailed reference solutions based on your needs. Our team focuses on tailoring one-stop solutions for customers to ensure that your production line achieves optimal efficiency and environmental sustainability. Contact us now to learn about our sand production line solutions.