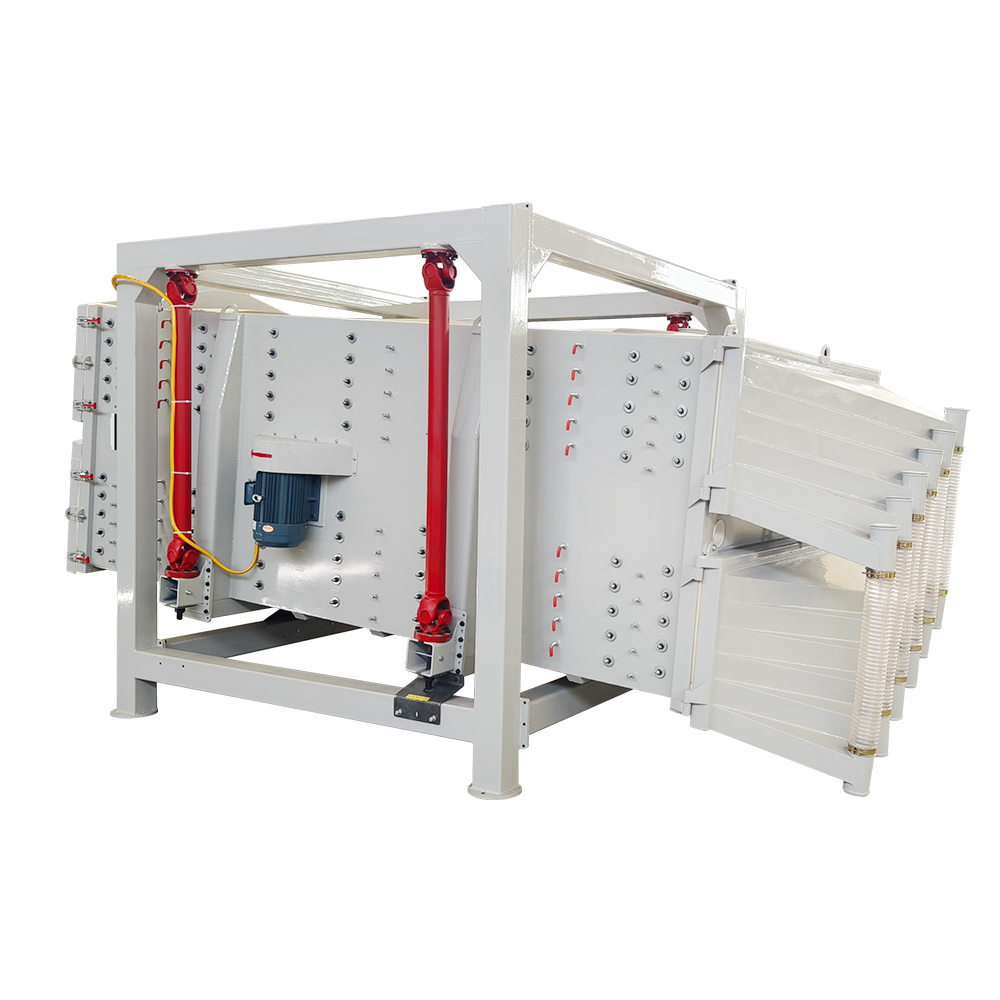

Vibrating sand screening machine is a gyratory sifter machine, an indispensable and important equipment in the sand and gravel production line. Its main function is to screen the crushed sand to remove coarse particles larger than 5mm and divide the sand into coarse, medium, and fine sand of different particle size grades to meet different construction and engineering needs.

The sand screening machine adopts advanced vibration screening technology, which uses high-frequency vibration to quickly separate sand on the screen. The sand screening machine has compact structure, stable operation and high screening efficiency. It is widely used in sand and gravel production lines to improve output and product quality.

- Model: FYBS-1536 , FYB-S2040

- Material: Carbon Steel

- Mesh Size: 2-300 mesh

- Layers: 1-10 layers

- Motor Power: 5.5kW/7.5 kW

- Capacity: 100kg – 15 Tons/hour

- Customized: Acceptable

Price: $14800.0 – 23400.0 / Set

Application

Vibrating sand screening machines are widely used in sand and gravel production lines in construction, highways, railways, bridges, water conservancy, and other industries. Whether it is a large sand and gravel production line or a small production line, the sand screening machine can exert an excellent screening effect and provide a strong guarantee for the production of high-quality sand and gravel products.

Vibrating sand screening machine is suitable for screening materials: quartz sand, industrial salt, fracturing sand, machine-made sand, plate sand, drying sand, ceramsite sand, orb sand, silica sand, polypropylene, drying mineral powder, calcium carbonate powder, Mica powder, talc powder, river sand, chemical fertilizers, etc.

Ceramic sand

Ceramic sand Perlite

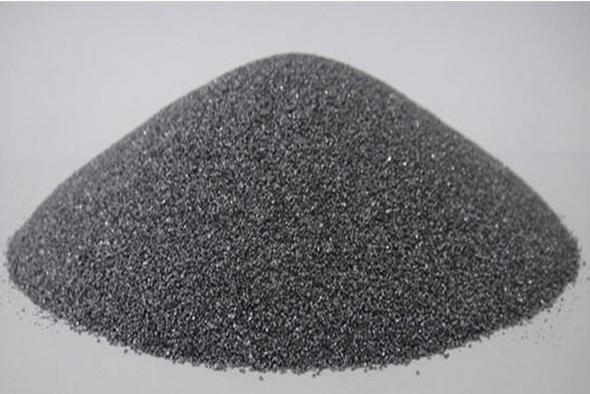

Perlite Emery

Emery Metal silicon powder

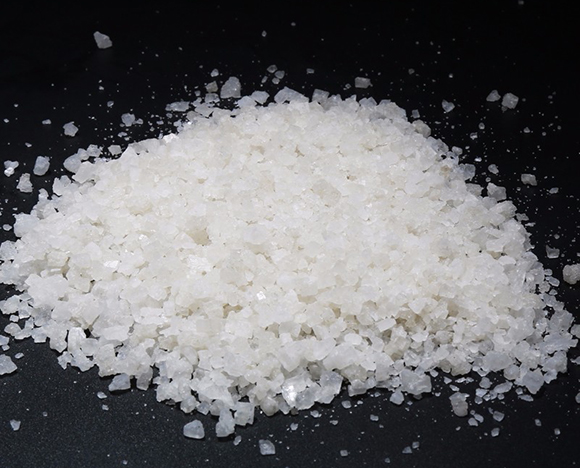

Metal silicon powder Industry salt

Industry salt Cork powder

Cork powder

Working Principle

After the Gyratory screen is started, the shaking body of the screen machine, that is, the screen box, reciprocates back and forth under the action of inertial force. The screen box drives the screen surface to shake periodically so that the materials on the screen surface make directional jumping movements together with the screen box.

During this period, materials smaller than the screen pore size fall to the lower layer through the sieve holes and become under-screen materials. Materials larger than the screen pore size are discharged from the discharge port after continuous rolling and jumping motion, thereby completing the screening work.

Vibrating sand screening machine details

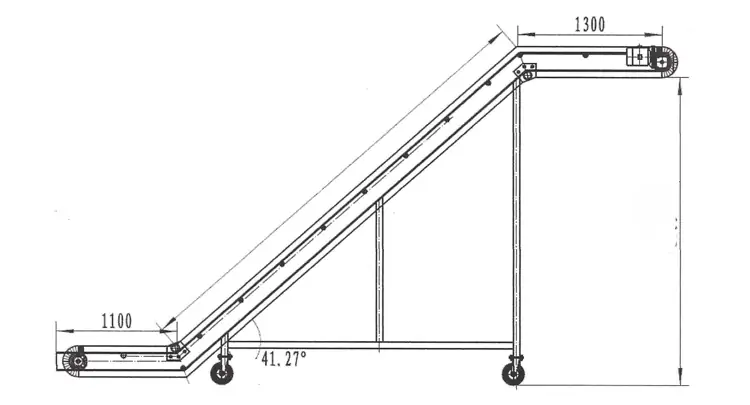

The vibrating sand screening machine is mainly composed of feed inlet, screen box, driving device, screen frame, support frame, vibration reduction device, discharge port, and other components.

Vibrating sand screening machine structure

Feed port: The original design attached to the back door has been changed, and the material distribution plate structure has been added to make the material distribution more effective and even. The weight of the back door is reduced, making the swinging motion of the feed end more powerful, making the materials put into the screen surface more efficient. Rapid dispersion screening.

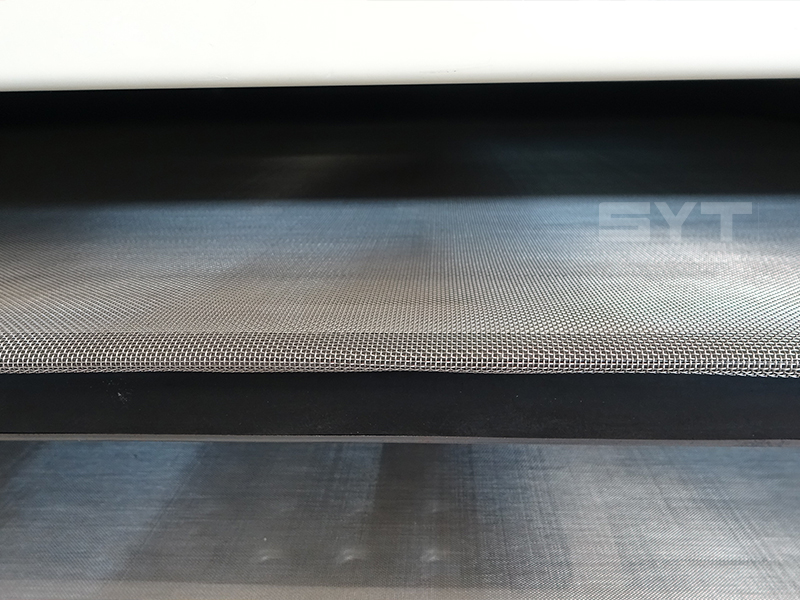

Screen box: including screen frame, screen mesh, screen grid, spring card bouncing ball, and other components. The screen frame is equipped with upper and lower layers of screen mesh. The screen mesh is tightened on the screen through spring cards set on the periphery of the screen grid. On the grid, the bouncing balls are placed in the squares of the screen grid.

Driving device: including driver, motor, locking sleeve, locking round nut, stop washer, and taper sleeve. The taper sleeve is fixed on the screen frame. The drive shaft of the driver is set in the taper sleeve and connected through the locking sleeve. Fixed its position.

Cardan shaft: The entire screen box is connected by a cardan shaft. When the screen machine makes a swinging motion, the cardan shaft also rotates, buffering and damping the rotational power, making the entire screen machine run more smoothly.

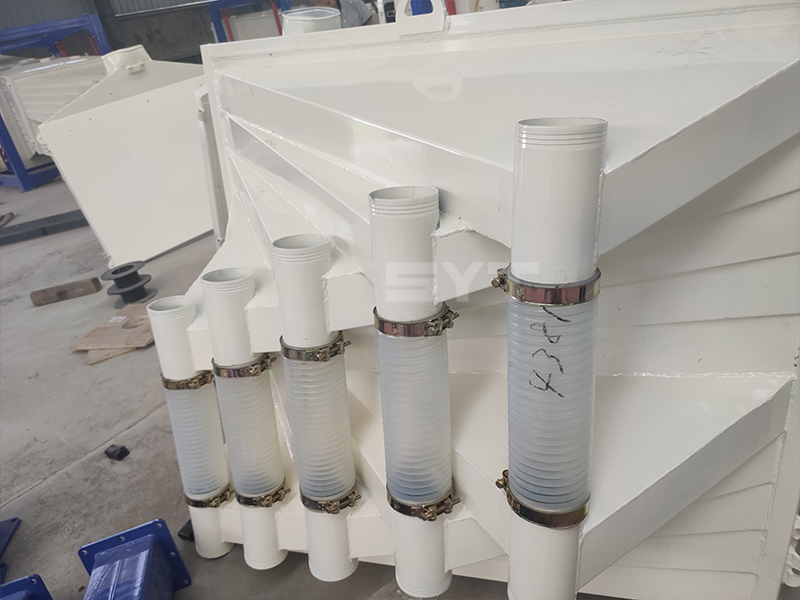

Discharge port: Various designs are carried out according to the customer’s material screening needs, which vary according to different mesh layer requirements. Our design focuses on facilitating large flow rates, fast and non-blocking outflow of the screen body, changing various angles, Various process methods such as increasing the diameter of the discharge pipe and reducing the outflow distance.

Specifications

The technical parameters of the sand screening machine include the number of screen layers, screen aperture, vibration frequency, processing capacity, etc. Specific parameters can be customized according to customer needs and production line scale to meet the actual needs of different customers.

| Model | Screen size | Screening area | Screen inclination | Layers | Power | Number of turns | Case travel |

|---|---|---|---|---|---|---|---|

| FYBS1536 | 1.5*3.5 m | 4.5-9 m2 | 5-8 | 1-10 | 5.5 | 180-260 | 25-60 mm |

| FYBS2040 | 2.0*4.0 m | 8-9 m2 | 5-8 | 1-10 | 7.5 | 180-260 | 25-60 mm |

Features

- The reciprocating rotary motion can quickly disperse and screen materials.

- The sand screening machine uses gentle swinging for screening without high-frequency vibration, which can effectively ensure that the original shape of the material particles is not destroyed.

- Screening within 0.3mm-180 mesh, the inclination angle of the screen surface is 0°-5°. The output of a single machine can reach 60 tons/hour.

- Multi-layer design of 1-5 layers (duplex can reach 10 layers), which can obtain finished products of various specifications at one time.

- Each layer of screen mesh is equipped with a screen mesh anti-clogging cleaning device. The screening machine continuously cleans the mesh mesh during operation to ensure that the mesh mesh does not block holes and extend the operating cycle.

- Fully enclosed structure, dust does not fly.

- Stable operation: The sand screening machine operates stably and reliably, with low maintenance costs and long service life.

- Adjustable output: By adjusting the number of layers and aperture of the screen, it can meet the production needs of different outputs.

Videos

We have a wealth of sand screening machine application videos, allowing you to more intuitively understand the operating principle, screening process and actual results of the equipment. Through the video, you can have a deeper understanding of the advantages and features of the sand screening machine.

Customer Site

We have successfully provided sand vibrating screening machine equipment to many sand and gravel production companies, and have won unanimous praise from customers. Customer feedback shows that the sand screening machine performs very well in increasing output, improving product quality and reducing maintenance costs, and has made an important contribution to improving customers’ production efficiency.