Overview

Tungsten Carbide Powder is a vital industrial raw material widely used in high-end applications, including cemented carbide manufacturing, thermal spraying, aerospace, electronic components, and precision cutting tools. Due to its fine particle size and high brittleness, the screening process must ensure high-precision grading while preventing particle breakage, placing extremely high demands on screening equipment.

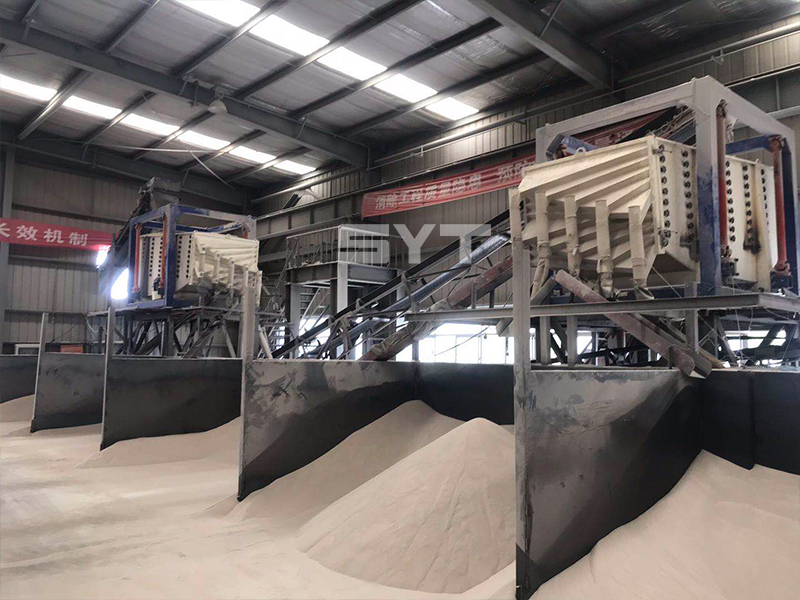

In August 2022, an Indian client visited our factory to observe the actual performance of the square gyratory screener in operation. Following technical discussions and trial runs, the client ultimately decided to purchase two sets of gyratory gcreener for tungsten carbide powder for their fine powder screening production line.

Customer Requirements

Based on the material properties of tungsten carbide powder, the customer has specified the following requirements:

The screening force must be gentle to prevent material breakage

- Target screening particle size range: 180–270 mesh

- Production capacity per unit screening area: Approximately 2 tons per hour

- Screening efficiency requirement: ≥95%

- Airborne dust concentration below 10 mg/m³

- Fully enclosed screening to prevent dust leakage and material loss

These conditions make it difficult for traditional high-impact vibrating screens to meet the requirements.

Tungsten Carbide Powder Material Properties Analysis

Pure tungsten carbide powder exhibits pronounced brittleness. Even when toughness is enhanced by adding metals such as cobalt or titanium, it remains susceptible to screening methods.

| Micro-grain WC powder | Description |

|---|---|

| Macro grain WC powder | For heavy machining applications requiring good wear resistance. Particle size > 1 micron |

| Micro grain WC powder | Widely used for toughness in mining tools and drill bits. Particle size 1-0.5 microns |

| Ultrafine grain WC powder | High hardness applications like cutting tools, die inserts. Particle size < 0.5 microns |

| Nanometer WC powder | Specialist applications demanding maximum abrasion resistance. Particle size under 100 nm |

Analysis of Screening Equipment Selection

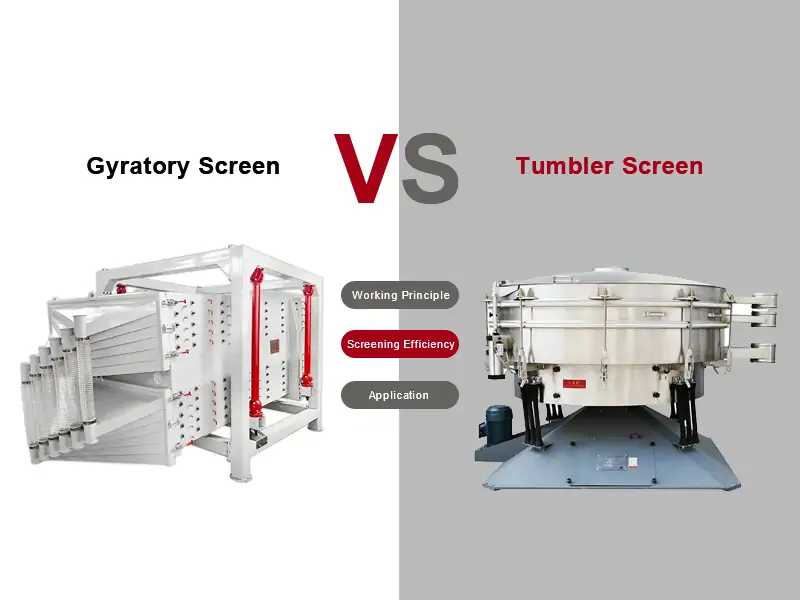

After comparing equipment such as rotary vibrating screens and ultrasonic vibrating screens, our engineers recommend adopting a gyratory screener.

Compared to traditional vibrating screens, the square gyratory screener offers the following advantages:

- Gentle screening motion reduces particle breakage

- Maintains high precision even under high mesh conditions

- Better suited for high-value-added fine powders

- Stable operation with extended screen life

Therefore, the gyratory screener for tungsten carbide powder emerges as the optimal solution.

Why choose the gyratory screener for Sieving Tungsten Carbide Powder?

Based on the customer’s production capacity and particle size requirements, our company customized an FYBS square gyratory screener featuring a dual-machine, five-layer screen structure.

Screening Configuration:

- 60 mesh: Coarse tungsten carbide powder

- 200 mesh: Fine powder screening

- 250 mesh: Precise classification of medium-fine powder

During actual operation, this Gyratory Screener achieved a stable throughput of 2–3 tons per hour, with screening efficiency and precision exceeding the customer’s expectations.

Equipment Performance and Technical Advantages

The FYBS square gyratory screener simulates manual screening trajectories by combining a low-angle screen surface with reciprocating rotary motion, achieving:

- High screening efficiency with high precision

- Effective prevention of qualified particles from being crushed

- Fully enclosed structure for low-dust screening

- Easy screen replacement with minimal maintenance time

This equipment is widely used in industries such as chemical powders, PVC, fertilizers, pharmaceuticals, ceramics, grains, and metal powders.

Rich Gyratory Screener Sifting Cases

Professional Gyratory Screener Manufacturer

As a professional gyratory screener manufacturer, Sanyuangtang Machinery specializes in the R&D, manufacturing, and customization of square gyratory screeners, with particular expertise in high-value fine powder screening applications.

Our manufacturing and service capabilities include:

- Custom screen layer configurations and mesh specifications

- Highly sealed dust-proof structural design

- Carbon steel / stainless steel material options

- Stringent quality inspection protocols

- Comprehensive installation, commissioning, training, and after-sales support

Each gyratory screener is engineered specifically to match material characteristics and production capacity targets.

Customer Feedback

The customer stated that after commissioning the gyratory screener for tungsten carbide powder, the powder screening process has achieved stable operation, uniform particle size distribution, and significant dust control. The equipment fully meets their high-end powder production and environmental requirements. They highly praised both the equipment performance and the customized service provided.