The wood chip screener is also called a four-vibration source square swinging wood chip screen because the whole machine has four excitation points. It is widely used in processing and screening wood chips, sawdust, biomass energy, alternative fuels, RDF and other materials. It has the characteristics of large output and high screening efficiency and is suitable for grading block or granular dry materials. The wood chip screening equipment can be used in conjunction with a chipper to effectively separate fine and overlong materials from wood chips, or separate mineral components from waste wood to facilitate subsequent recycling or heat treatment. Our company has successfully applied for a national invention patent for this product.

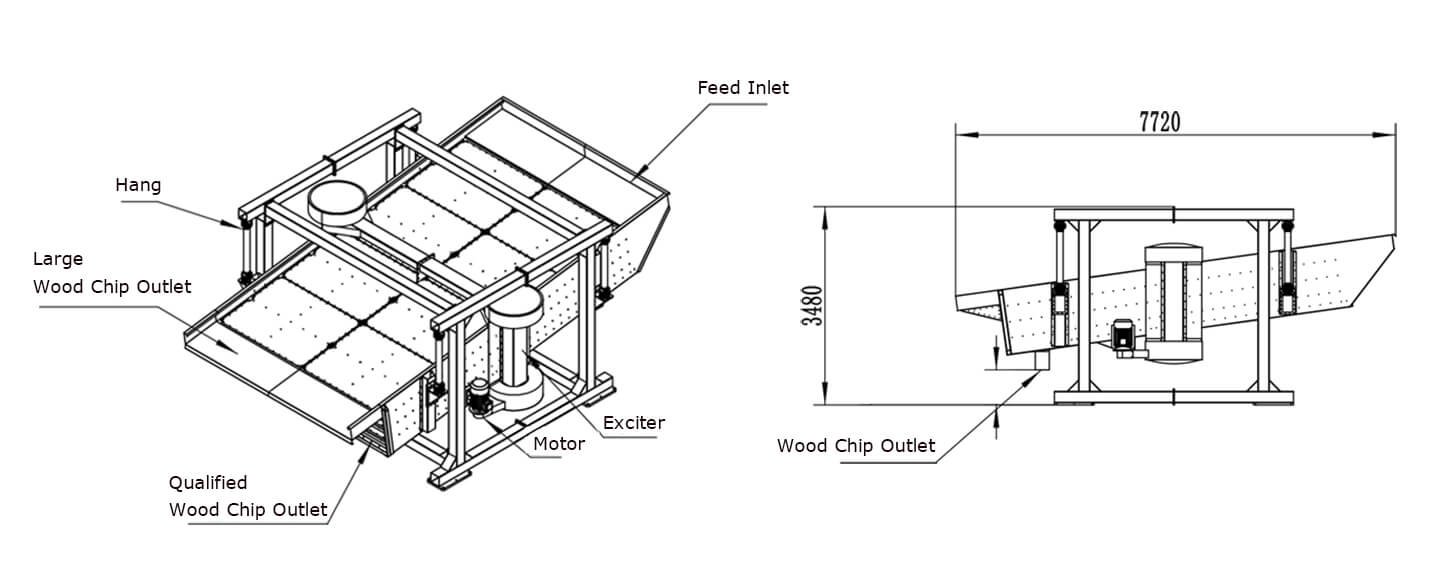

- Dimensions: 7.6m*5.2m*3.4m

- Screening size: 5~55mm

- Screening layers: 1~5 layer

- Capacity: 600~1000m³/h

- Application: Wood Chips, Wood Fiber, Wood Pellets, Sawdust, Mulch, Biomass Feedstock, Hog Fuel, Paper / OCC, etc.

Price: $23600.0 – 36600.0 / Set

Wood Chip Screener Working Principle

The wood chip screener oscillating screen is mainly powered by a 15KW permanent magnet synchronous motor, which is driven by a V-belt and a synchronous belt to produce a reciprocating elliptical swinging motion, which is transmitted to the screening bucket through the screen box, screen mesh, and other components, so that the wood chips jump and slide on the screen mesh, and finally achieve the classification of wood chips of different sizes.

Structures

The wood chip screener oscillating screen adopts a suspended structure mainly composed of legs, springs, screen box, screen, exciter, vibration motor, and other parts. The exciter bearing adopts imported bearings for high-speed rail, which is completely maintenance-free. The power source adopts a permanent magnet synchronous variable frequency motor with first-level energy efficiency, which is more lightweight, energy-saving, and has multiple complete protections. The equipment can be easily disassembled and installed, which is convenient for container transportation.

Details

Specifications

| Model | Dimensions (l * w * h) (m) | Screening Area (m²) | Sieve Layers | Motor Power (kw) | Production Capacity (m³/h) | Spindle Speed (r/min) | Vibration Amplitude(mm) | Tilt Angle |

|---|---|---|---|---|---|---|---|---|

| FYBS-4060 | 7.6*5.2*3.4 | 4*6 | 1~5 | 15 | 600~1000 | 200一300 | 60-70 | 8-10° adjustable |

wood chip screener Application

The wood chip screener is widely used in wood processing, pulp and paper making, biomass energy and other fields. Such as: wood chips, wood blocks, wood fiber, wood pellets, palm fiber, bamboo chips, coconut fiber, charcoal blocks, wood chips, slab wood, sawdust / shavings, plastics, mulch, compost, biomass, feedstock, c&d debris, refuse derived fuel, hog fuel, urban wood, paper / occ, , etc.

Features

Efficient screening

Through multi-layer screens and continuous vibration, the material has a long travel on the screen, with high screening accuracy and large processing capacity.

Wide Range of Applications

The aperture size of the screen can be adjusted according to actual needs, and wood chips of different materials, shapes and sizes can be processed.

Large-capacity

According to on-site tests, it can screen 18 cubic meters in one minute, which is equivalent to 1080 cubic meters in one hour, which can meet the needs of large-scale production.

Plastic Spraying and Baking Process

The whole machine adopts spray paint treatment technology, with beautiful appearance, bright surface, not easy to stick to dirt, easy to clean and maintain, and has good anti-corrosion, anti-rust and weather resistance.

Warranty Service

The whole machine is guaranteed for two years. If there are any quality problems within two years, the three-guarantee policy will be implemented. We promise to provide users with timely and professional after-sales service to ensure stable operation of the equipment and user experience.

“Ease Sieve” Brand Design Concept

The whole machine adopts the new design concept of “Ease Sieve“, with more scientific structural force, simple operation, convenient maintenance, good power balance, and more stable equipment operation.

Customized Design

One-stop custom Wood screening solutions

Get a Quote

Wood Chip Screener Manufacturer

We are a professional wood chip screener manufacturer, focusing on overall screening and conveying solutions for 30 years. With continuous technological research and innovation, we have successfully developed and launched many efficient gyratory screener products. Contact our team and we can solve your wood mill screening problems and help you improve your production efficiency.