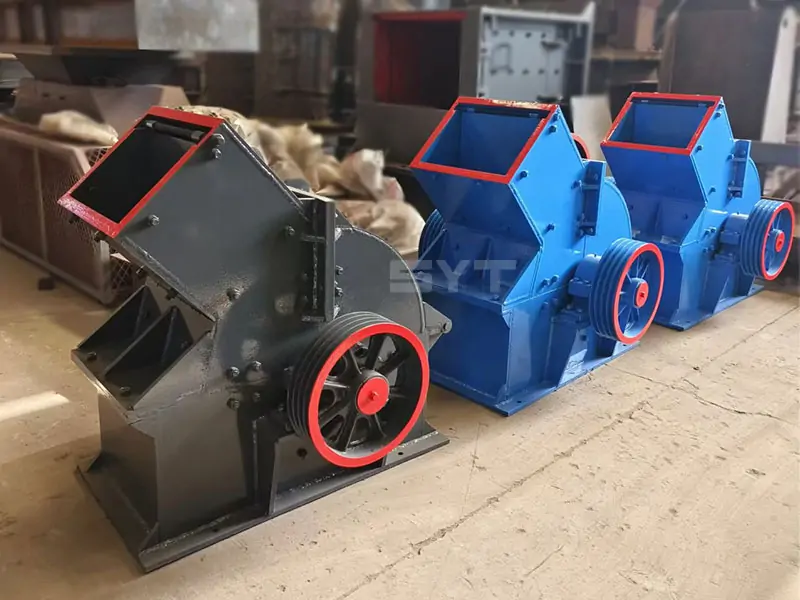

The PE hammer crusher machine, also known as a hammer mill crusher, is an industrial crushing equipment specially used for crushing medium-hardness and brittle bulk mineral materials. It has the advantages of a simple structure, a large crushing ratio, high production efficiency, and convenient maintenance. It can effectively process various materials with compressive strength not exceeding 150MPa and humidity kept below 15%, the particle size of the hammer crusher can reach less than 5mm.

- Model: PC

- Feed size: ≤350mm

- Production capacity: 5-100tons/hour

- Application: crushing of large materials such as limestone, rock, slag, coke, coal, salt, gypsum, alum, brick, tile, etc.

Price: US $1,500.00 -$ 8,000.00 / Set

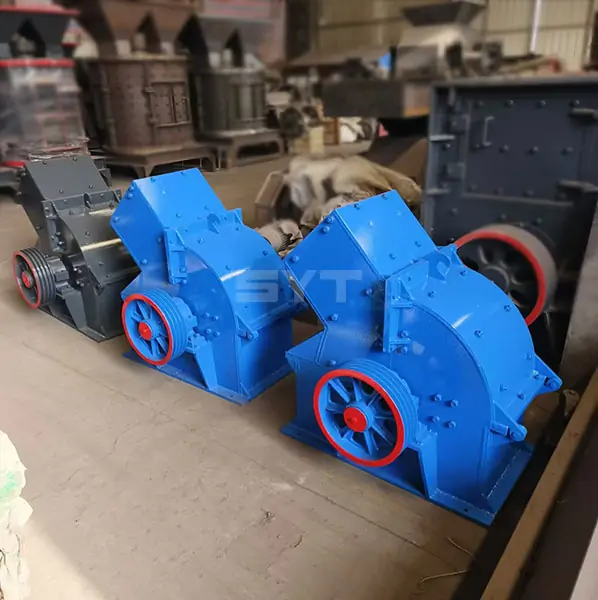

Hammer Crusher Machine Working Principle

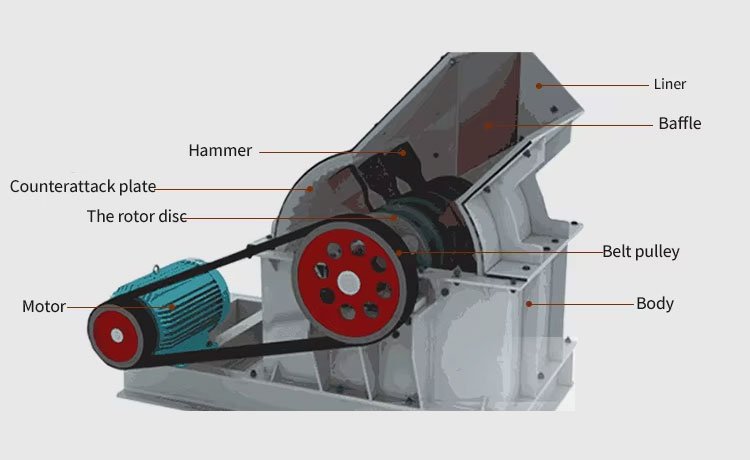

The hammer crusher machine consists of a box, a rotor, a hammer, an impact plate, a screen plate and other components. The main working part of the hammer mill crusher is the rotor with hammers, also known as the hammer head. Therefore, the working principle of the hammer crusher is mainly to hammer, shear and grind the material through the high-speed rotating hammer head. A screen is provided at the bottom of the rotor. The crushed material with smaller particle size is discharged by the screen, and the material larger than the screen hole size is retained in the cavity for further crushing. The equipment can adjust the grate gap according to user requirements and change the discharge particle size to meet the different needs of different users.

Specifications

| Model | SPC | Parameters | Capacity (t/h) | Motor power(KW) | Weight (t) | Size |

|---|---|---|---|---|---|---|

| PC-64 | φ600ⅹ400 | Charge<100mm, discharge<15mm | 12-15 | 18.5 | 1.3 | 1935*110*1122 |

| PC-86 | Φ800ⅹ600 | Charge<200mm, discharge<10mm | 18-24 | 55 | 2.5 | 2523*1525*1020 |

| PC-0808 | Φ800ⅹ800 | Charge<50mm, discharge<5mm | 15-20 | 55 | 5.18 | 1590*1935*1390 |

| PC-108 | Φ1000ⅹ800 | Charge<200mm, discharge<13mm | 20-50 | 110 | 6.5 | 3514*2230*1515 |

| PC-1010 | Φ1000ⅹ1000 | Charge<200mm, discharge<13mm | 40-60 | 115 | 7.6 | 2230*2220*1515 |

Features

feed particle size is large

The feed particle size is large, and coarse crushing, medium crushing and fine crushing can be achieved at one time.

Large feeding and fine discharging

Can crush material from 600-3500 mm to 25 mm or less.

high reduction ratio

It has a high reduction ratio (range 10-25, maximum up to 50) and high production efficiency.

resistant to impact and wear

The hammer head and screen plate are made of high-quality chromium-manganese alloy, which is resistant to impact and wear.

finished product has uniform particle size

The crushed finished product has uniform particle size, which is conducive to subsequent screening operations.

convenient operation and maintenance

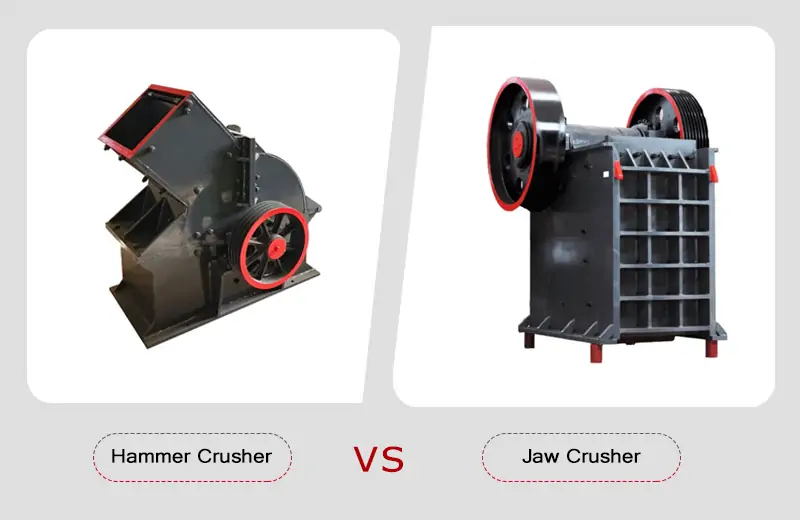

It has a simple structure, small size, easy operation, and convenient operation and maintenance.

Application

Hammer crusher machines are widely used in mining, construction engineering, road paving, and other industries. They can crush a variety of hard materials including limestone, construction waste, red brick blocks, concrete blocks, coal gangue, smelting slag, coke, etc. In addition, it is also good at processing materials with high fiber strength and elasticity such as wood and paper, as well as recovering asbestos fibers from asbestos cement waste. Hammer crushers are not only suitable for crushing and sand-making production lines but can also be used as a substitute for cone crushers in mineral processing production lines.

Basalt

Basalt Coal Gangue

Coal Gangue Lime Stone

Lime Stone Quartz

Quartz River Pebbles

River Pebbles