This premix and breading production line is specially designed for handling various food ingredients, widely used for premix powders such as wheat flour, starch, powdered sugar, spice powders, and seasonings. After precise proportioning, the raw materials undergo a fully automated process from feeding to finished product packaging through the system, ensuring stable product quality and high production efficiency.

- Material Processed: Food Ingredients

- Capacity: 1000 kg/h

- Equipment Configuration: Vacuum feeder, bag dump station, inline sifter machine, V-type mixer, packaging machine, etc.

Process Flow

Raw material preparation → Raw material feeding → Screening → Mixing → Packaging → Quality inspection → Coding → Finished product output

System Configuration

The premix and breading production line system typically includes the following components:

- Raw Material Handling Equipment: Such as automatic bag dump stations and vacuum feeders for feeding and conveying materials.

- Screening Equipment: Like an inline sifter machine for screening raw materials to remove impurities and large particles.

- Mixing Equipment: Such as mixers for evenly blending raw materials according to preset ratios.

- Packaging Equipment: Like automatic packaging machines for quantitatively packaging the mixed premix or breading powders.

- Conveying Equipment: Such as roller conveyors for transporting raw materials, semi-finished, and finished products within the production line.

- Inspection Equipment: Like weight checkers to ensure that the packaged products meet the net weight standards.

- Coding Equipment: Such as inkjet printers to print key information like production dates and batch numbers on the packaging.

Recommended Equipment

Application Materials:

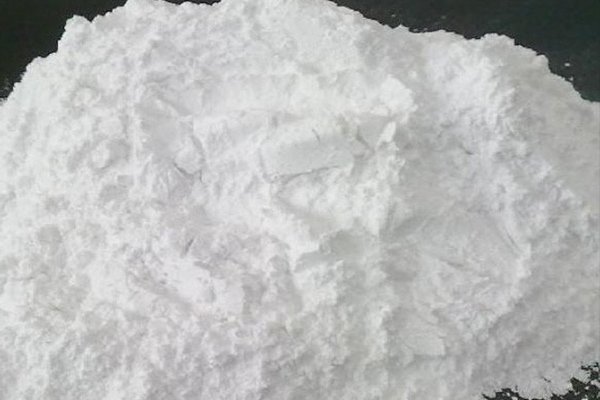

The premix and breading production line system is mainly used in the food industry, particularly in the baking, catering, food processing, and packaging sectors. It is suitable for processing the following materials: wheat flour, starch, powdered sugar, salt, pepper, spice powder, leavening agents, emulsifiers, stabilizers, milk powder, protein powder, etc.

Flour

Flour Sugar Powder

Sugar Powder Starch

Starch Spices

Spices

System Features:

- High Automation: The entire process from raw material feeding to product packaging is automated, reducing manual intervention, increasing production efficiency, and ensuring product consistency.

- Dust-Free and Environmentally Friendly: Utilizing manual bag dump station and vacuum conveying technology to effectively control dust pollution, protect the production environment, and safeguard worker health.

- Precise Control: Equipped with accurate measuring and screening devices to ensure the precision of raw material input and mixing ratios, improving product quality.

- Efficient Mixing: The system uses a high-efficiency mixer to ensure uniform mixing of ingredients in a short time, enhancing production efficiency while retaining the nutritional content and flavor of the raw materials.

- Flexible and Versatile: Capable of adjusting production formulas and packaging specifications based on different food ingredients and customer requirements, meeting diverse market demands.

- Smart Inspection: Integrated weight checkers and inkjet printers provide automatic quality inspection and product traceability, enhancing product safety and market competitiveness.

- Easy Maintenance: The system’s design allows for easy cleaning and maintenance, reducing maintenance costs and extending equipment life.

- Energy Efficient: By optimizing the production process and using high-efficiency, energy-saving equipment, the system reduces energy consumption, lowers production costs, and aligns with green production concepts.

Premix and Breading Production Line Photos on Site