Have you ever noticed the bouncing balls jumping on the screen when the vibrating screen is working? So, what is the special function of these bouncing balls? Today, let’s take a look.

Table of Contents

Function Of Bouncing Balls in Vibrating Screen

The bouncing ball, as an integral part of the vibrating sieve screen, has the main function of knocking the screen up and down to prevent materials from adhering to and clogging the screen.

Bouncing Balls Size

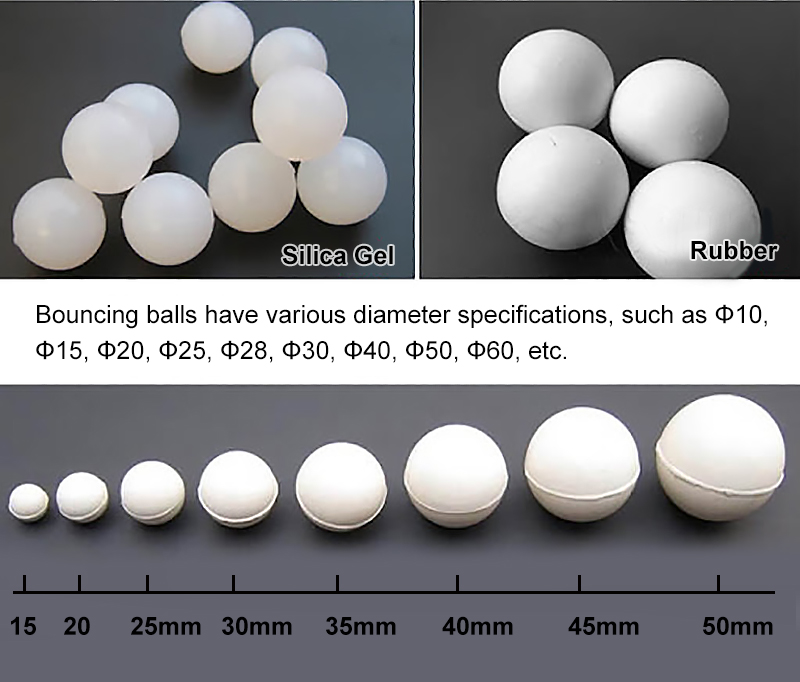

ouncing balls have various diameter specifications, such as Φ10, Φ15, Φ20, Φ25, Φ28, Φ30, Φ40, Φ50, Φ60, etc. Among them, Φ25 and Φ28 are commonly used specifications, while Φ40, Φ50, and Φ60 are mainly used in mining vibrating screens. middle.

3 Types Of Vibrating Screen Bouncing Balls

When choosing a bouncing ball, we should fully consider its material to meet performance needs under different conditions.

1. Silicone Gel Ball

Silicone bouncing balls have good elasticity and wear resistance and are not easy to fall. It is widely used in the screening of food, medicine, and other materials.

2. Rubber Bouncing Ball

Natural rubber bouncing balls are suitable for general material screening processes.

3. PTFE Bouncing Ball

PTFE bouncing balls can be soaked in oil and are specially used for screening oily liquid materials.

Function Of The Vibrating Screen Bouncing Balls

The bouncing ball impacts the screen mesh by moving up and down in the vibrating screen machine, thereby preventing or reducing clogging. The screen mesh of the vibratory screen is an important component of the vibrating screen. There are bouncing balls cleverly installed between the screen mesh and the mother mesh. These bouncing balls can weaken the adhesion of materials on the mesh through their unique impact effect and achieve a clean screen. The function of the net is to improve the efficiency of materials passing through the net.

Suggestions For Using Vibrating Screen Bouncing Balls

- Select the appropriate size and form of the bouncing ball to ensure that it matches the mesh size of the vibrating screen and the characteristics of the powder to be screened.

- Use an appropriate amount of bouncing balls. Too much or too little will affect the screening effect.

- The bouncing balls should be evenly distributed on the screen surface.

- Replace worn or damaged bouncing balls regularly.

In short, although the bouncing ball is a small accessory, it cannot be ignored. Through reasonable selection and use of bouncing balls, screening efficiency and accuracy can be effectively improved, bringing significant benefits to enterprise production.