Vibrating screen mesh as a key component of the vibrating screen, plays an extremely important role in material screening. In the impurity removal and screening of the vibrating screen, because the screen needs to be in direct contact with the materials, it is easy to wear and needs to be replaced regularly. So how to choose the appropriate screen mesh to extend the service life of the vibrating screen mesh and reduce the time-consuming maintenance and repair caused by frequent screen changes?

How to choose right vibrating screen mesh?

First, you need to consider the following factors:

- Material: Choose the appropriate screen material according to the nature of the material to be screened and the environmental requirements. Common materials include steel wire, polyethylene, stainless steel, etc.

- Aperture size: Determine the aperture size of the screen according to the particle size of the material to ensure that materials with the required particle size can be effectively screened.

- Strength and wear resistance: Select a screen with sufficient strength and wear resistance according to the wear and tear conditions of the material and usage requirements to increase the service life.

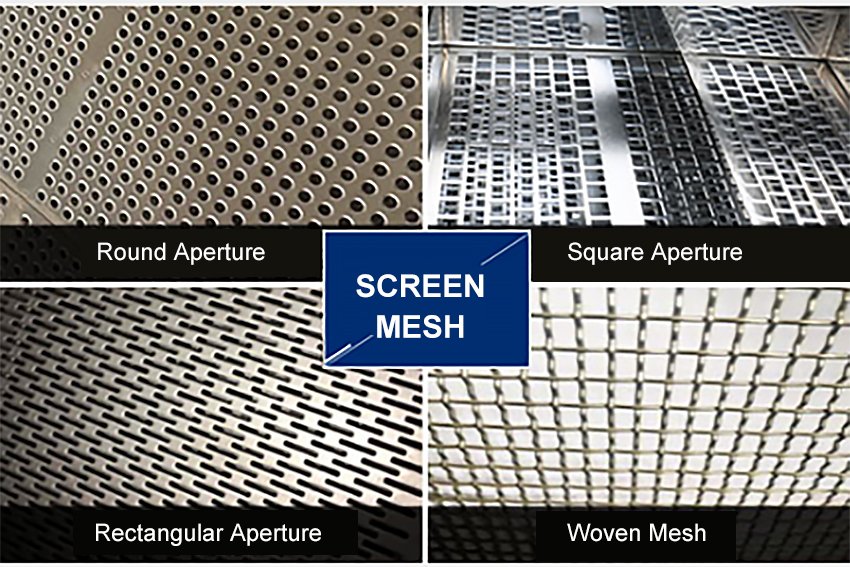

- Opening shape: Choose the appropriate opening shape according to the shape of the material and screening requirements. Common ones include square holes, round holes, rectangular holes, etc.

- Surface treatment: Choose the appropriate surface treatment method according to the adhesion and easy clogging of the material, such as galvanizing, sandblasting, etc.

Vibrating Screen Mesh Materials

- Use a vernier caliper to measure: When measuring, the diameter of the material with the largest particle size should be used as the standard. When selecting the screen aperture, it should be larger than the particle size diameter. This is mainly because the aperture of the material is 10% larger during the screening process, which can be sufficient for unloading without affecting the material. Screening quality.

- The proportions of different materials vary greatly. For example, the weight of sand and gravel is between 2.5 and 3 tons per cubic meter, and the weight of grain materials is between 800 and 1,000 kilograms per cubic meter. If the material has the same particle size, the specific gravity will be different and the screening speed will be quite different. The moisture content will also affect Material screening efficiency, so after knowing the particle size, and consulting with the vibrating screen manufacturer based on specific needs, the most suitable aperture can be selected.

- Materials with high viscosity. Materials that are too sticky will easily stick to the mesh and block holes during the screening process. When selecting the screen mesh, it is not easy to choose punching plates or slit mesh. Instead, woven mesh with a smaller wire diameter should be selected. In addition, in the mesh frame, The effect will be better if an ultrasonic device is added to the site.

- For materials with lighter specific gravity, the screening efficiency will be greatly reduced. For example, chili powder and starch have shortcomings such as slow discharging and low mesh penetration rate during screening. It would be better to choose a tumbler screen or air flow sifter machine.

vibrating Screen Mesh Size

Many customers do not understand the relationship between vibrating screen mesh size and particle size and do not know how to choose a suitable vibrating screen and screen mesh. Please read the following article.

The mesh size of the screen is the number of holes in the screen, the number of holes per square inch. Therefore, the larger the mesh number, the smaller the aperture. Usually, mesh number However, the thickness of the wire used in weaving the mesh is different, and different national standards are also different. Currently, there are three commonly used standards: the United States, the United Kingdom, and Japan. Among them, the standards of the United States and the United Kingdom are relatively close, and the Japanese standards are quite different. The vibrating screens exported from China U.S. standards are widely adopted.

Vibrating Screen Mesh Sizes Chart

| Mesh Size | Wire Diameter (mm) | Pore Diameter(mm) | Mesh Size | Micron(um) |

|---|---|---|---|---|

| 150 | 0.035 | 0.134 | 100 | 150 |

| 150 | 0.038 | 0.131 | 150 | 106 |

| 150 | 0.06 | 0.109 | 200 | 75 |

| 160 | 0.035 | 0.124 | 250 | 58 |

| 160 | 0.06 | 0.099 | 300 | 48 |

| 165 | 0.04 | 0.114 | 400 | 38 |

| 165 | 0.05 | 0.104 | 500 | 25 |

| 165 | 0.065 | 0.089 | 600 | 23 |

| 180 | 0.035 | 0.106 | 800 | 18 |

| 180 | 0.045 | 0.096 | 1000 | 13 |

| 180 | 0.05 | 0.091 | 5000 | 2.6 |

| 180 | 0.058 | 0.083 | 10000 | 1.3 |

When purchasing a vibrating screen, you should choose a screen that can meet the screening needs based on the characteristics of the materials to be screened and the size of the particles. The commonly used Taylor system uses the number of holes per inch as the sieve size, which is called mesh. The so-called mesh number refers to the particle size or thickness of the material. The general definition refers to the number of meshes in an area of 1 square inch, that is, the number of meshes of the screen. How many meshes can the material pass through in this area, that is, the mesh number is defined as:

- For example, 200 mesh means that the material can pass through a screen with 200 meshes in 1 square inch.

- For example, 100 mesh means that the material can pass through a screen with 100 meshes in 1 square inch.

- For example, 50 mesh means that the material can pass through a screen with 50 mesh openings in 1 square inch.

The mesh size of the screen is inversely proportional to the hole diameter and particle size, and directly proportional to the number of holes. That is: the larger the mesh number, the more pores, and the smaller the pore diameter, indicating the finer particle size of the material; the smaller the mesh number, the fewer the number of pores, and the larger the pore diameter, indicating the larger the material particle size. Therefore, we must choose the best vibrating screen mesh to meet our work needs based on the particle size of the materials to be screened.

If you have a specific question about screen mesh or need further information, feel free to contact us!