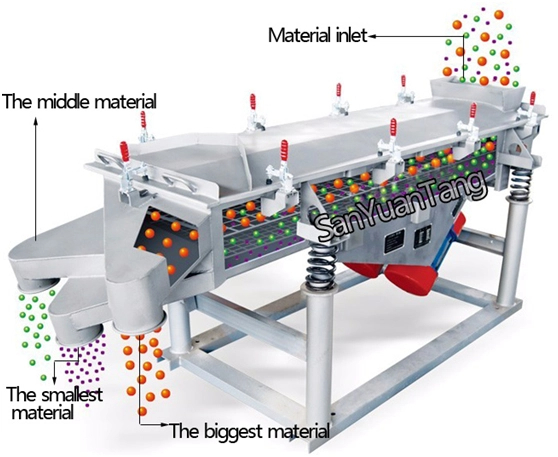

SYZ linear vibrating screen uses an excellent vibrating motor as a power source, so the materials can be thrown up on the sieve and forward to make a straight movement. It can be equipped with a single or multi-layer screen to achieve grading, removing impurities, removing dust, testing, washing selecting, dehydration, cleaning raw material, separation of iron from the material, etc.

- Model: SYZ825,SYZ1225,SYZ1530,SYZ520,SYZ1030

- Material: Stainless Steel/Carbon Steel

- Layers: 1-5 Layers Customized

- Power: 2*0.75/2*3.0kw

- Capacity: 300-4000 kg/hour

Price: $2500-3600 /Set

Application

- Chemical industry: resin pigment, color masterbatch, medicine, grease, paint, palette, etc.

- Organic fertilizer industry.

- Plastics industry.

- Abrasive material and ceramic industry: building sand, mica, alumina, abrasive, refractory material, slurry, etc.

- Food industry: sugar, salt, alkali, gourmet powder, yeast powder, pollen, palm fiber, etc.

- Paper-making industry: coated slurry, exhaust liquid, paper-making liquid, and wastewater reclamation, etc.

- Metallurgy and mining industry: quartz sand, ore, titanium oxide, zinc oxide, etc.

- Mechanical industry: casting sand, powder metallurgy, electromagnetic material metal powder, etc.

Spices

Spices Medicine granules

Medicine granules Coffee Beans

Coffee Beans Plastic particles

Plastic particles Ceramic sand

Ceramic sand Manufactured sand

Manufactured sand Fertilizer

Fertilizer Plastic Particles

Plastic Particles Perlite

Perlite

Working Principle

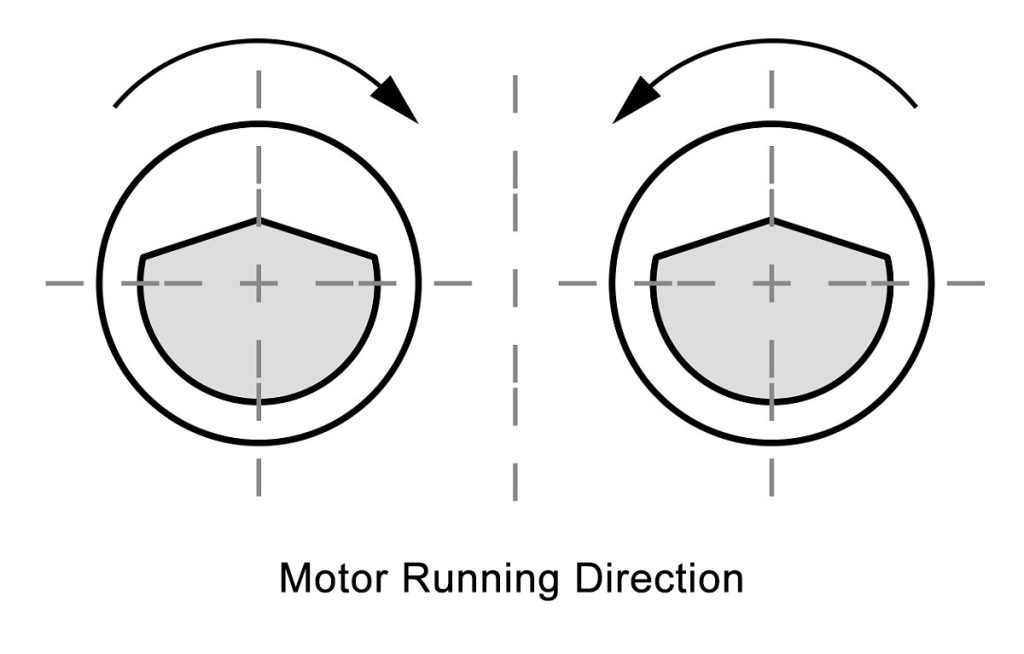

Linear vibrating sieve uses double vibrating motors to drive, when two motors rotate synchronously and reversely, exciting forces generated by eccentric block are resolved in parallel to the direction of the motor axis and then united as one across the motor axis direction, so its movement track is linear.

There is an inclination angle between the two motor axises relative to the screen deck. Under the influence of the resultant force of exciting force and the material itself weight, materials are thrown up to make leapfrog and linear movement forward on the vibrating screen deck to screen and grade the material and applied in flowing line to achieve automatical operation.

Structures

Screen frame: The rigid structure that holds the screen mesh or sieve cloth in place.

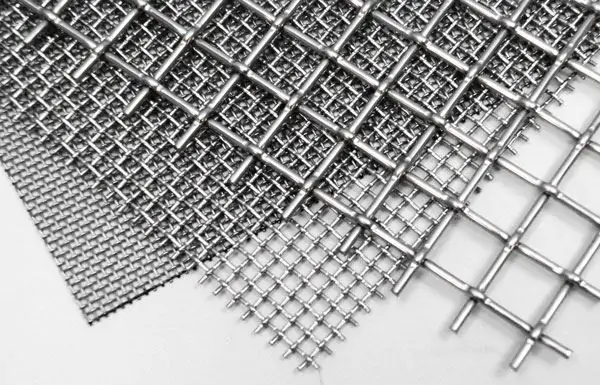

Screen mesh or sieve cloth: This is the actual screening surface where the material is separated based on its size. The size of the openings in the mesh determines the size of the particles that can pass through.

Vibrating motor: An electric motor that generates the vibrations needed to move the material on the screen surface. The vibrating motor is typically mounted on the screen frame and equipped with eccentric weights to create the necessary vibration.

Vibration isolation springs: These are used to support the screen frame and reduce the transmission of vibrations to the surrounding structures.

Feed inlet and discharge outlet: The points where the material is fed onto the screen and where the screened material is collected and separated into different fractions.

Features

Technical Parameter

| Model | SYZ-520 | SYZ-525 | SYZ-530 | SYZ-1020 | SYZ-1025 | SYZ-1030 | SYZ-1225 |

|---|---|---|---|---|---|---|---|

| Dimension (mm) | 500×2000 | 500×2500 | 500×3000 | 1000×2000 | 1000×2500 | 1000×3000 | 1200×2500 |

| Material diameter (mm) | 0.074-20 | 0.074-20 | 0.074-20 | 0.074-40 | 0.074-40 | 0.074-40 | 0.074-40 |

| Shake frequency(time/min) | 960 | 960 | 960 | 960 | 960 | 960 | 960 |

| Gradient | 1-7 | 1-7 | 1-7 | 1-7 | 1-7 | 1-7 | 1-7 |

| Amplitude | 1-4.5 | 1-4.5 | 1-4.5 | 1-4.5 | 1-4.5 | 1-4.5 | 1-4.5 |

| The layer number | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

| POWER (kw) | 2×(0.37-0.75) | 2×(0.37-0.75) | 2×(0.37-0.75) | 2×(0.75-1.1) | 2×(0.75-1.5) | 2×(0.75-1.5) | 2×(0.75-1.5) |

Custom according to your needs

Linear Vibrating Screen is available in a variety of models, and we can customize them according to your specific requirements, such as size, number of layers, screens, outlet, and inlet, including gate type, mobile wheel type, elevated type, and airtight type Formula, etc. Ensuring customers can find the perfect machine for their unique needs.

Stainless Steel

Stainless Steel Stainless Steel

Stainless Steel Carbon Steel

Carbon Steel Carbon Steel

Carbon Steel