Overview

A UK-based building materials company specializes in the production and sale of construction materials, with manufactured sand being one of its core products. This sand is widely used in concrete and infrastructure projects. As market demands for uniform particle size and reduced stone powder content in manufactured sand continue to rise, the existing screening equipment can no longer meet current production requirements.

To enhance screening efficiency and improve the gradation accuracy of finished sand, the company plans to procure new screening equipment. After evaluating multiple screening solutions, the client learned about the gyratory swing screen and proactively contacted Sanyuantang Machinery to seek a customized solution.

Material Analysis

1. Material Characteristic Analysis

Manufactured sand exhibits high stone powder content during production and demands strict particle size grading. Practice demonstrates that rectangular or circular screen apertures struggle to meet high-precision grading requirements, whereas square-mesh screens prove more suitable for gyratory swing screens processing manufactured sand, effectively enhancing screening accuracy.

2. Screen Aperture Selection Principles

Screen aperture size directly impacts manufactured sand quality and output:

- Larger apertures yield finer finished sand with lower stone powder content

- Smaller apertures produce coarser finished sand with higher stone powder content

Based on industry research and field experience, the recommended screen aperture size for manufactured sand production is 3.5–4.5mm. This range is highly suitable for square gyratory swing screen applications.

3. Screen Inclination Design

To balance screening efficiency and throughput, the screen inclination is typically designed at approximately 20° according to the gyratory vibrating screen manufacturer engineering experience. This facilitates uniform material distribution and continuous screening.

Selection of machine-made sand powder removal equipment

The production of manufactured sand typically contains 10%–20% stone powder (≤75μm).

- Appropriate levels of stone powder improve concrete workability and enhance compressive and flexural strength.

- Excessive stone powder content significantly degrades concrete performance.

Therefore, stone powder removal is critical for controlling manufactured sand quality. After a comprehensive comparison of wet and dry processing methods, Sanyuantang mechanical engineers recommend a dry classification solution based on Gyratory Swing Screens. This approach effectively removes excess stone powder while maximally preserving the original particle size distribution structure.

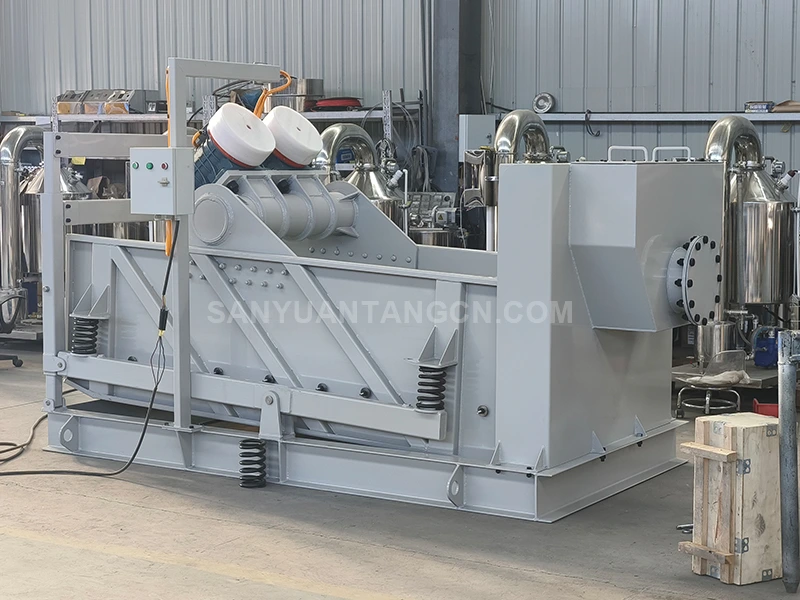

Custom Gyratory Swing Screen Solution

Custom Gyratory Swing Screen Solution

Based on the customer’s production capacity and screening precision requirements, Sanyuantang Machinery custom a square gyratory swing screen with the following key specifications:

- Five-layer screen structure for simultaneous classification of multiple particle sizes

- The mesh size for each screen layer is precisely matched to customer specifications

- Employs a gentle gyratory motion to ensure uniform material distribution across the screen surface

- Adjustable vibration frequency and screen angle for precise control over different particle sizes

This Gyratory Swing Screen has demonstrated outstanding performance in actual operation. It delivers stable finished sand particle size distribution and high screening efficiency, achieving a single-unit processing capacity of 2000 kg/h, fully meeting the customer’s production requirements.

Sanyuantang Machinery Manufacturing and Custom

As a professional gyratory swing screen manufacturer, Sanyuantang Machinery possesses comprehensive manufacturing and custom capabilities, providing tailored solutions for diverse applications, including:

- Custom of screen mesh layers, screening particle size, and mesh material

- Carbon steel or stainless steel structure options

- Custom voltage and electrical standards (supports 400V / 50Hz / 3-phase)

- Modular design for quick screen replacement and routine maintenance

The entire equipment features energy efficiency, environmental friendliness, stable operation, user-friendly operation, and compact structure, making it suitable for diverse industrial production environments.

Customer Feedback

Customer feedback indicates that since the gyratory swing screen commenced operation, the screening efficiency of manufactured sand has significantly improved. The finished sand exhibits uniform particle size, minimal impurities, and controllable stone powder content, fully meeting the client’s production standards for high-quality manufactured sand. The client expressed high recognition of Sanyuantang Machinery equipment performance and customized services.