Vibrating spiral elevators can also be called vertical spiral conveyors, spiral conveyors, cooling vibration spirals, etc. Spiral Elevator is applicable to convey and lift materials of powder, block, and short fiber. The materials can not only be lifted but also be dried and cooled during lifting.

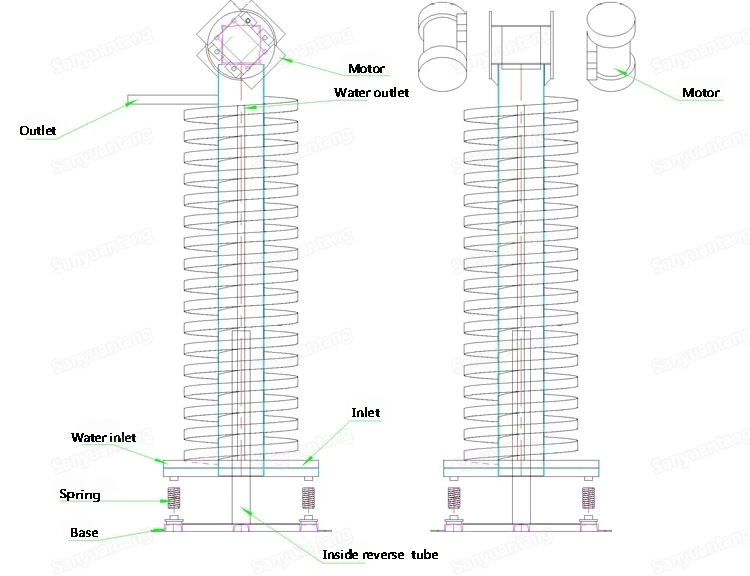

According to the customer’s request, the vibration spiral elevator can also be designed to classify the materials and convey flammable and explosive materials. Other functions can be realized by tailor-made service e.g. heating, cooling, drying, spreading, etc: water cooling vibrating spiral conveyor.

Price: $3,750 – $6,350 /Set

Application

Vibrating spiral elevator is suitable for powder, particle solid material of low viscosity.

- Food industry: Sugar powder, starch, milk powder, egg powder, rice powder, food additive, seasoning, spice, etc.

- Chemical industry: Fertilizer, detergent powder, sodium carbonate, talcum powder, dyestuff, rubber, PVC resin, pigment, cosmetics, coatings, Chinese medicine powder, fiber, etc.

- Metal, metallurgy industry: Copper powder, nickel powder, aluminum powder, copper granule, ore alloy powder, welding powder, battery material, abrasive powder, fire-proof material, etc.

PP plastic granules

PP plastic granules Masterbatch

Masterbatch PVC resin powder

PVC resin powder Xylitol

Xylitol Carbon particles

Carbon particles Rubber Granules

Rubber Granules Chicken Essence

Chicken Essence Chinese medicine granules

Chinese medicine granules Calcium sulfite granules

Calcium sulfite granules Lithium manganate

Lithium manganate Sodium carbonate

Sodium carbonate Heavy calcium powder

Heavy calcium powder

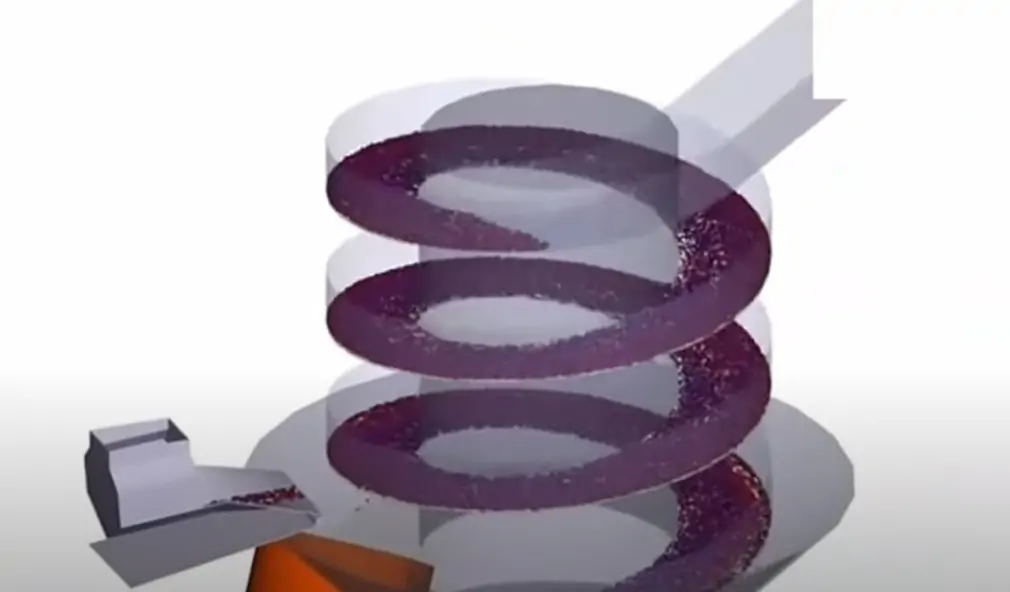

Working Principle

The vibrating motor of the Vibrating spiral elevator is installed in the lower part of the conveying tower, two vibrating motors are symmetrically cross-mounted, the conveying tower consists of the tube body and the spiral conveying groove welded around the tube body, the conveying tower is seated on the vibration-damping device, which consists of the base and vibration isolation spring.

When the vertical spiral conveyor works, according to the principle of self-synchronization of double vibration motors, the vibration motor generates the excitation force, forcing the whole conveying tower to make the space compound vibration of horizontal circular motion and upward vertical motion, and the materials in the spiral groove are subjected to the effect of conveying groove, making the circular motion of throwing at a uniform speed and moving upward along the conveying groove, to complete the conveying of the materials upward (or downward).

Specifications

| Model | Diameter of Spiral chute(mm) | Lifting height(m) | Speed(r/min) | Double amplitude(mm) | Power(kw) |

|---|---|---|---|---|---|

| SZC300 | 300 | ≤4.0 | 960 | 6-8 | 2*0.4 |

| SZC500 | 500 | ≤6.0 | 6-8 | 2*0.75 | |

| SZC600 | 600 | ≤8.0 | 6-8 | 2*1.5 | |

| SZC800 | 800 | ≤8.0 | 6-8 | 2*2.2 | |

| SZC900 | 900 | ≤8.0 | 6-8 | 2*3.0 | |

| SZC1200 | 1200 | ≤8.0 | 6-8 | 2*4.5 | |

| SZC1500 | 1500 | ≤8.0 | 6-8 | 2*5.5 | |

| SZC1800 | 1800 | ≤8.0 | 6-8 |

Videos

Features

Spiral elevators can be customized to meet specific industry needs. They can be designed with multiple inlets and outlets, different angles or heights, and can even be integrated with other equipment such as cooling or drying systems.

Spiral elevators provide a continuous and smooth vertical movement of materials. This allows for a constant flow of goods without the need for frequent starts and stops.

Efficient Space Utilization

Spiral elevators have a compact design that saves valuable floor space.

Increased Throughput

The spiral design enables a higher throughput compared to traditional elevators or conveyors.

Gentle Material Handling

Spiral elevators are gentle on materials, reducing the risk of damage or breakage. Suitable for delicate or fragile products that require careful handling, such as electronics or glassware.

Safety

Spiral elevators are equipped with safety features such as emergency stop buttons, safety interlocks, and guarding systems, ensuring the safety of operators and preventing accidents.

Customer Site