Vertical spiral conveyors also called vertical conveyors, spiral conveyors, spiral elevators, etc. Vertical conveyors are applicable to convey and lift materials of powder, block, and short fiber. The materials can not only be lifted but also be dried and cooled during the process of lifting.

According to the customer’s special request, a vertical conveyor can also be designed to classify the materials and convey flammable and explosive materials. Other functions can be realized by tailor-made service e.g. heating, cooling, drying, spreading, etc: water cooling vibrating spiral conveyor.

Price: $3,750 – $6,350 /Set

Application of Vertical Spiral Conveyor

- Food industry: Sugar powder, starch, milk powder, egg powder, rice powder, food additive, seasoning, spice, etc.

- Chemical industry: Fertilizer, detergent powder, sodium carbonate, talcum powder, dyestuff, rubber, plastic particles, PVC resin, pigment, cosmetics, coatings, Chinese medicine powder, fiber etc.

- Metal, metallurgy industry: Copper powder, nickel powder, aluminum powder, copper granule, ore alloy powder, welding powder, battery material, abrasive powder, fire-proof material, etc.

PP plastic granules

PP plastic granules Masterbatch

Masterbatch PVC resin powder

PVC resin powder Xylitol

Xylitol Carbon particles

Carbon particles Rubber Granules

Rubber Granules Chicken Essence

Chicken Essence Chinese medicine granules

Chinese medicine granules Calcium sulfite granules

Calcium sulfite granules Lithium manganate

Lithium manganate Sodium carbonate

Sodium carbonate Heavy calcium powder

Heavy calcium powder

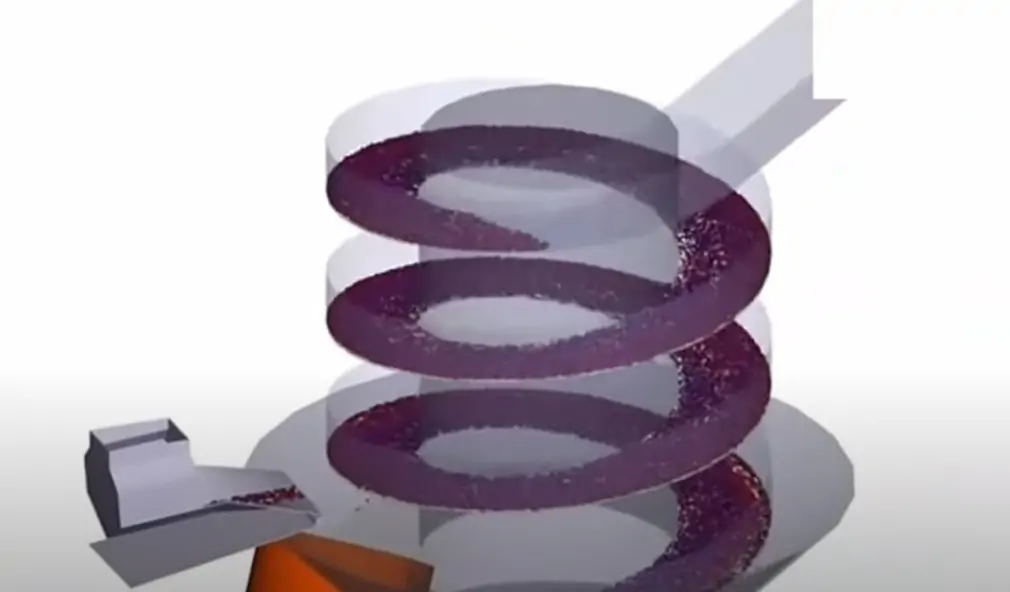

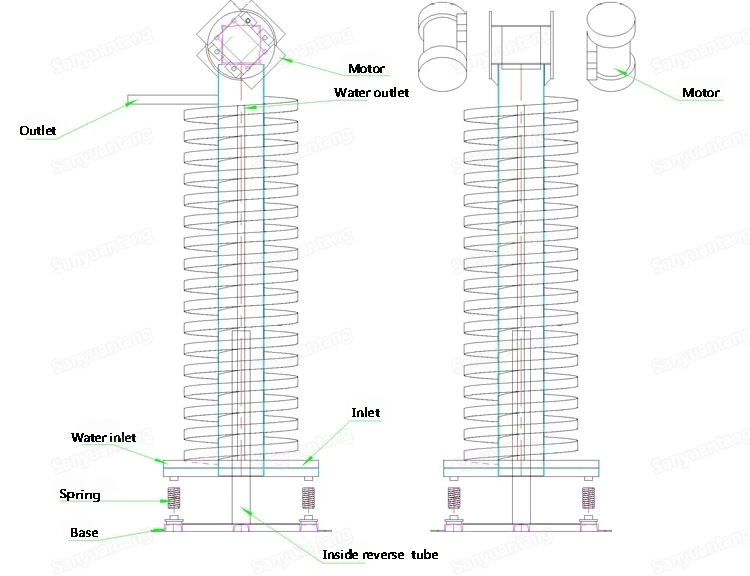

Working Principle

The vibrating motor of the vibrating spiral conveyor is installed in the lower part of the conveying tower, two vibrating motors are symmetrically cross-mounted, the conveying tower consists of the tube body and the spiral conveying groove welded around the tube body, the conveying tower is seated on the vibration-damping device, which consists of the base and vibration isolation spring.

When the vertical conveyor works, according to the principle of self-synchronization of double vibration motors, the vibration motor generates the excitation force, forcing the whole conveying tower to make the space compound vibration of horizontal circular motion and upward vertical motion, and the materials in the spiral groove are subjected to the effect of conveying groove, making the circular motion of throwing at a uniform speed and moving upward along the conveying groove, to complete the conveying of the materials upward (or downward).

Videos

Technical parameters of Vibration Spiral Conveyor

| Model | Diameter of Spiral Chute(mm) | Lifting height(m) | Speed(r/min) | Double amplitude(mm) | Power(kw) |

|---|---|---|---|---|---|

| SZC300 | 300 | ≤4.0 | 960 | 6-8 | 2*0.4 |

| SZC500 | 500 | ≤6.0 | 6-8 | 2*0.75 | |

| SZC600 | 600 | ≤8.0 | 6-8 | 2*1.5 | |

| SZC800 | 800 | ≤8.0 | 6-8 | 2*2.2 | |

| SZC900 | 900 | ≤8.0 | 6-8 | 2*3.0 | |

| SZC1200 | 1200 | ≤8.0 | 6-8 | 2*4.5 | |

| SZC1500 | 1500 | ≤8.0 | 6-8 | 2*5.5 | |

| SZC1800 | 1800 | ≤8.0 | 6-8 |