When changing materials in a Vibrating Spiral Elevator, it is essential to thoroughly clean the spiral conveying layer. Proper cleaning not only prevents cross-contamination between batches but also ensures smooth conveying performance, stable product quality, and longer equipment service life.

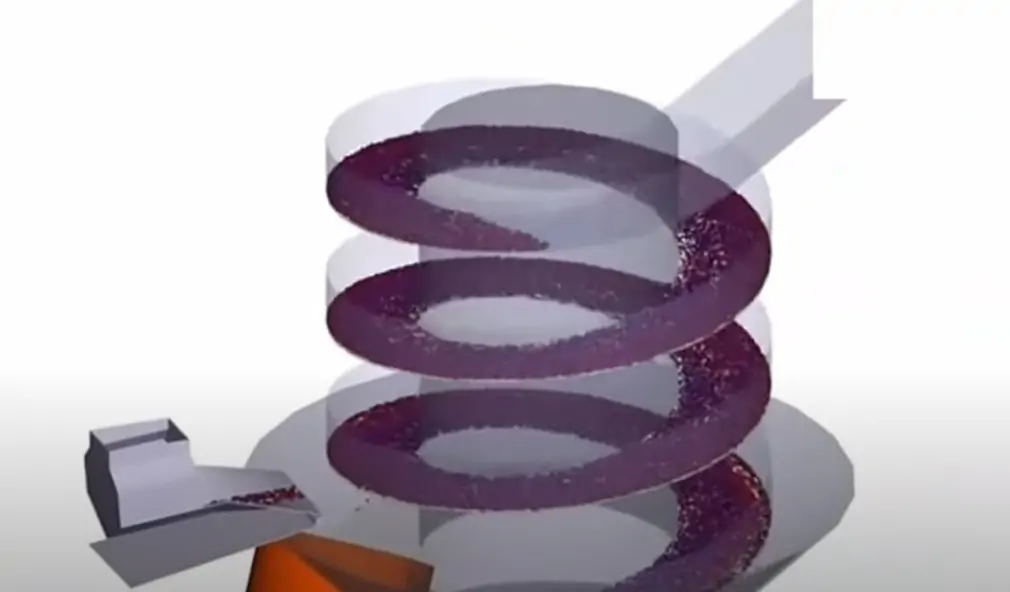

The spiral conveying layer is the core working surface of the elevator. Any residual particles left behind can affect material flow, cause blockage, and even lead to product defects in sensitive industries such as food, chemicals, pharmaceuticals, and plastics.

In this guide, we’ll explain why cleaning is critical and share practical methods for effectively cleaning the spiral conveying layer.

Why You Must Clean the Spiral Conveying Layer When Changing Materials

During operation, materials move upward along the spiral track driven by vibration. However:

- Fine particles can stick due to surface tension

- Granules may lodge in gaps and uneven edges

- Different materials may react or contaminate each other

If the spiral layer is not cleaned:

- Cross-contamination may occur

- Material flow becomes unstable

- Blockage and downtime increase

- Product purity and quality are compromised

That’s why every material change should include a full process to clean the spiral conveying layer of your Vibrating Spiral Elevator.

Types of Spiral Conveying Layers

Depending on the design, spiral layers may include:

- Water-cooled spiral layer: used for hot materials

- Air-cooled spiral layer: for heat-sensitive products

- Ordinary conveying layer: standard lifting applications

Due to different edge-pressing and manufacturing processes, ordinary spiral layers may have slight unevenness. These areas easily trap powders or granules, making cleaning more difficult.

Best Methods to Clean the Spiral Conveying Layer

Sanyuantang recommends physical, dry-cleaning methods that are efficient, safe, and do not damage the spiral surface:

- Towel-assisted lifting

- Compressed air blowing

- Industrial vacuum cleaning

These methods are ideal for most material changeovers in a Vibrating Spiral Elevator.

Step-by-Step Guide to Clean the Spiral Conveying Layer

Step 1: Towel-Assisted Vibration Cleaning

- Before shutdown, place a soft, clean towel at the feed entrance of the spiral track.

- Lightly dampen the towel to improve adsorption (avoid excess moisture).

- Start the vibration motor, and the towel will move upward along the spiral path.

- As it reaches the discharge outlet, use clamps or tools to remove it safely.

- Let the towel and collected material fall into a prepared container.

This step removes most bulk residues from the spiral surface.

Step 2: Air Pump Blowing for Remaining Particles

After towel cleaning:

- Use a high-efficiency air pump or compressed air gun

- Adjust to a suitable pressure

- Blow along the spiral surface and into gaps

- This removes fine particles that remain on the conveying layer.

Always ensure safe operation and avoid directing airflow toward sensitive components.

Step 3: Vacuum Cleaning for High Cleanliness Requirements

For industries with strict hygiene or fine powders:

- Use a small industrial vacuum cleaner

- Equipped with a proper nozzle and filter system

- Gently vacuum along the spiral surface

This method ensures complete removal of dust and micro-residues without damaging the layer.

Safety Tips During Cleaning

- Always follow lockout/shutdown procedures

- Wear protective gloves and masks

- Use non-metal tools to avoid scratching

- Do not use corrosive liquids unless approved

Protecting the spiral surface helps maintain smooth conveying and extends equipment life.

Benefits of Regularly Cleaning the Spiral Conveying Layer

By cleaning your Vibrating Spiral Elevator properly, you can:

- Prevent cross-contamination

- Ensure material purity

- Maintain stable conveying efficiency

- Reduce blockage and downtime

- Extend equipment service life

- Improve overall production quality

Regular cleaning is a small step that brings long-term operational benefits.

Conclusion

When changing materials in a Vibrating Spiral Elevator, taking time to clean the spiral conveying layer is essential for reliable performance and product quality. Using towel-assisted lifting, air blowing, and vacuum cleaning provides an efficient, safe, and practical solution for most industrial applications.

Need Professional Support?

If you’re looking for a custom Vibrating Spiral Elevator or expert advice on cleaning and maintenance, feel free to contact us. Our team is ready to help you optimize your conveying system for your specific materials and processes.

Contact us today for technical support and solutions!