Square Gyratory Vibrating Screen On-Site Test

Real wood chip screening case using a Square Gyratory Vibrating Screen. On-site test with actual wood shavings led to a confirmed order within 2 hours.

Real wood chip screening case using a Square Gyratory Vibrating Screen. On-site test with actual wood shavings led to a confirmed order within 2 hours.

This case study presents the application of an ultrasonic vibrating screen in fine quartz powder screening. By integrating an ultrasonic screening system and a five-layer vibrating screen structure, the solution effectively solved high-mesh clogging, improved micron-level screening accuracy, and achieved stable multi-specification classification in a single pass.

This case study presents an integrated screening, cooling, and conveying solution designed for high-temperature plastic pellets, including color masterbatch and PVC pellets. By combining a linear vibrating screen with a water-cooled and air-cooled vertical vibrating elevator, the system achieves rapid pellet cooling from 130℃ to 35℃, stable vertical lifting, and continuous output of 400 kg/h within limited installation space, while effectively preventing pellet deformation and adhesion.

Project Overview By adopting Sanyuantang Machinery’s tumble…

Project Overview Recently, we received a request from a Mexican c…

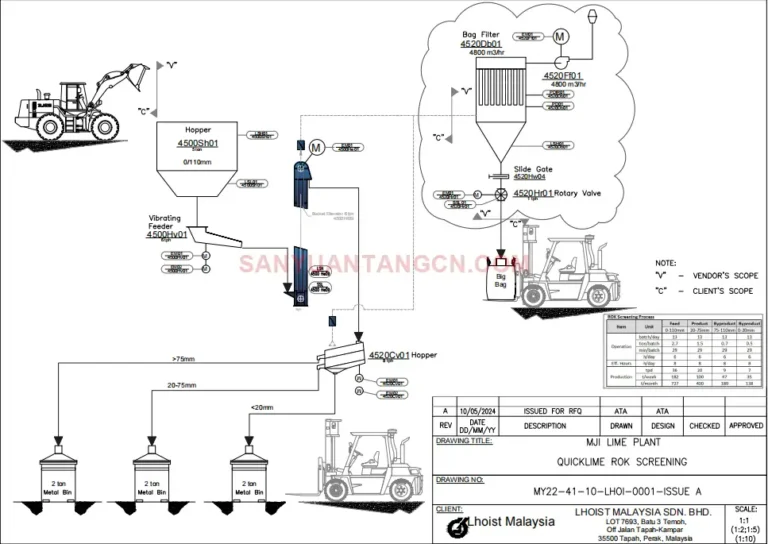

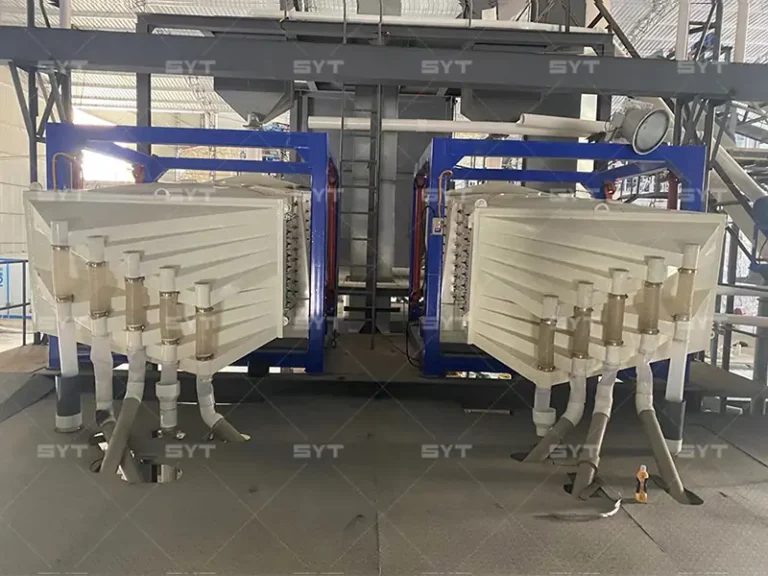

Successful Lime Production Line Equipment project for LHOIST Group. Customized silo, conveying system and lime plant solution. Learn more.

This customer is a well-known feed company from Macedonia, with a…

In the pharmaceutical process, the particle size of Chinese medic…

In the preparation process of drug raw materials and intermediate…

Boost seasoning production with Sanyuantang’s Inline Vibratory Sifter. Our inline sifter machine ensures high efficiency, removes impurities, guarantees food safety, and supports custom solutions.

A renowned daily chemical company from the UAE has successfully e…

Background A small cannabis processing company based in Californi…

Sanyuantang Machinery provides a custom Ultrasonic Vibrating Sieve for high-efficiency, precise powder screening. A US cosmetic company achieved stable 100–200kg/h output with improved product quality and reduced downtime. Ideal for cosmetic, pharmaceutical, and food powders, this tailored solution boosts production efficiency and ensures consistent powder separation. Contact Sanyuantang Machinery today to optimize your powder processing with a reliable, high-performance screening solution.

A material processing company in the United States needed a set o…

Overview In November 2023, a Malaysian food company specializing …

Overview This client is an innovative US-based company engaged in…

Overview The Korea Starch Processing Factory, a renowned local st…

Square gyratory swing screen for manufactured sand sieving with precise grading, powder removal, and 2000 kg/h capacity.

Overview On May 9, 2022, a Greek customer ordered two linear vibr…

High-efficiency gyratory screener for tungsten carbide powder screening. Gentle screening force, 95% efficiency, low dust, 2–3 t/h output.

Industrial Gyratory Screener for calcium powder and calcium carbonate screening. High efficiency, large output, multi-deck classification case.

In the rubber manufacturing industry, an industrial round sifting…

This customer sent us an inquiry from Alibaba, wanting to co…

The rotary airflow sifter machine is different from ordinary rota…

Gyratory Vibrating Screen Project Details In May 2023, Sanyuantan…

Introduction A client specializing in mica powder production soug…

“The silica sand vibrating screen is great. It not only has…

内容结束

内容结束