Overview

Calcium Powder(Calcium) is a vital industrial powder material widely used in the building materials, chemical, plastics, rubber, and coatings industries. During actual production, enterprises place high demands on the screening efficiency, particle size precision, and stable production capacity of calcium powder.

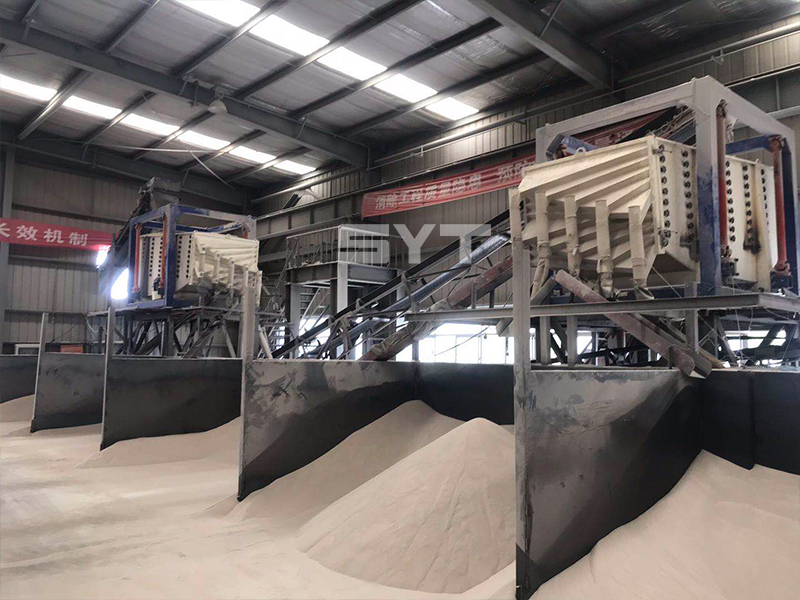

A calcium powder manufacturer sought to introduce a large output gyratory screener to enhance the screening efficiency and multi-stage classification capabilities of calcium carbonate powder. After thorough comparisons, the client selected our company to collaborate on customizing an industrial screening machine—a gyratory screener for calcium powder.

Customer Requirements

Based on the customer’s existing production line and product positioning, the following specific requirements have been established for the screening equipment:

- Suitable for screening calcium powder with high powder content

- Capable of multi-layer screening to achieve multi-particle size classification

- Delivers high screening efficiency and precision

- Ensures stable operation suitable for continuous production

- Meets high-volume production demands

Traditional screening equipment struggles to balance precision and throughput, failing to fully satisfy the above requirements.

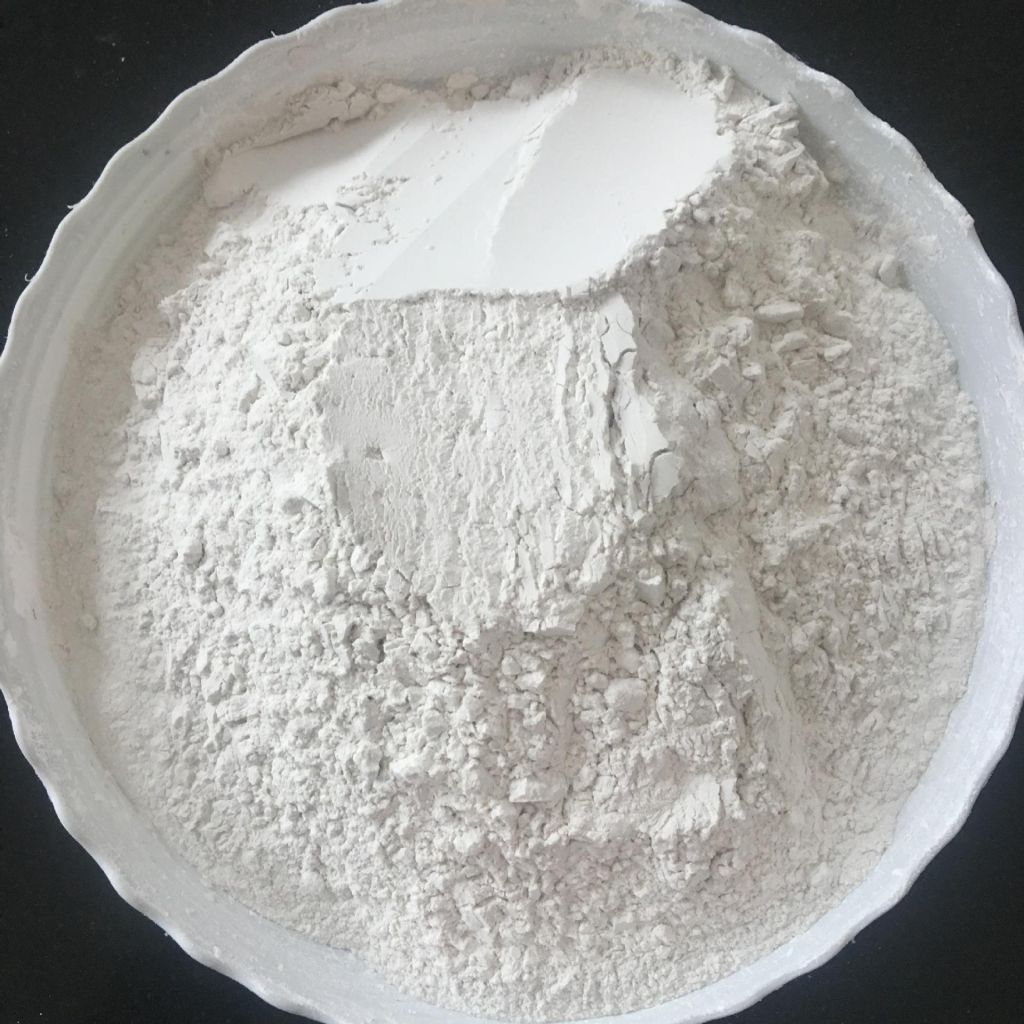

Calcium Carbonate Powder

Calcium Carbonate Powder is primarily derived from limestone and exhibits the following screening characteristics:

- High powder content with a tendency to cake

- Wide particle size distribution requiring multi-stage screening

- High demands on equipment stability during continuous operation

Therefore, when selecting an industrial powder screening machine, it is essential to ensure screening precision while balancing processing capacity and operational reliability.

Analysis of Screening Equipment Selection

After comparing linear vibrating screens, rotary vibrating screens, circular tumbler screens, and other equipment, our engineering team concluded that the gyratory screener is more suitable for industrial screening applications involving calcium powder.

Compared to traditional vibrating screens, the square gyratory screener offers the following advantages:

- Smooth screening motion with uniform material distribution across the screen surface

- Maintains stable screening accuracy even under high mesh conditions

- Better suited for simultaneous multi-layer and multi-particle size classification

- Achieves both large output and high precision

Therefore, the gyratory screener for calcium carbonate powder screening is the final recommended solution.

Custom Gyratory Screener Screening Solutions

Based on the client’s production targets and particle size requirements, we configured a double vibration source gyratory screener to achieve multi-layer simultaneous screening.

Equipment and Test Parameters:

- Screened Material: Calcium Powder

- Powder Content: Approximately 80%

- Test Duration: 1.5 tons / 20 minutes

- Equipped Screen Mesh Sizes: 20 mesh / 40 mesh / 60 mesh / 80 mesh / 120 mesh

During actual trial operation, this gyratory screener demonstrated stable performance, meeting the customer’s comprehensive requirements for high efficiency and multi-stage classification.

Screening Results and Application Effects

During the trial operation, the equipment demonstrated the following advantages:

- Stable particle size distribution of calcium powder

- Simultaneous multi-layer screening with clear gradation

- High-efficiency screening significantly boosts throughput per unit time

- Smooth operation with excellent continuous working performance

After on-site inspection and confirmation of screening results, the customer immediately ordered two gyratory screeners for their calcium carbonate powder production line.

Why choose the gyratory screener for calcium powder sifting?

1. Rich Gyratory Screener Sifting Cases

Why Choose a Gyratory Screener for Calcium Powder Screening

The core advantages of the Gyratory Screener in calcium powder screening include:

- High screening efficiency and precision

- Easy-to-replace screens for simplified maintenance

- Self-cleaning mesh design to minimize clogging issues

- Excellent overall sealing for energy efficiency and environmental protection

- Suitability for extended continuous industrial operation

These features make it the ideal equipment for calcium carbonate powder screening.