What is an Ore Gyratory Vibrating Sieve?

An Ore Gyratory Vibrating Sieve is a primary piece of equipment used in the mining industry for material classification, dewatering, de-mediation, and desliming operations. It primarily selects vibrating screens based on different operational stages. Commonly used vibrating screens include the Linear Vibrating Screen and the Gyratory Vibrating Sieve, with their main differences lying in vibration trajectories, structural characteristics, and applications. In the mining screening industry, the core objectives we primarily face are how to enhance production efficiency, ensure stable production, reduce maintenance costs, and achieve safe production. Let’s take a look at some common screening issues in the mining industry and their solutions.

Common screening issues in the mining industry and their solutions

The Ore Gyratory Vibrating Sieve is a key piece of equipment in mining production processes, and its operational status directly impacts overall efficiency and costs. In pursuit of core objectives such as enhancing production efficiency, ensuring stable production, reducing maintenance costs, and prioritizing safe production, we often encounter the following typical screening issues. Below, I provide corresponding solutions:

Material Blockage of the Screen Mesh:

Issue: Sticky, wet materials, fine particles, or flaky materials easily block the screen openings, causing a sharp drop in screening efficiency and requiring frequent shutdowns for cleaning.

Solution: A ball-cleaning device continuously impacts the bottom of the screen mesh to clear blockages; an ultrasonic cleaning system uses high-frequency vibrations to break down adhesive layers; a stepped screen surface design or steeply angled installation accelerates material flow; and a strong vibration mode (such as the three-dimensional motion of a gyratory vibrating sieve) promotes material discharge through the screen.

Excessive screen mesh wear:

Issue: High-hardness, sharp-edged minerals (such as iron ore or quartz sand) cause significant impact and wear on the screen mesh.

Solutions: Polyurethane screen plates or rubber-edged screens provide excellent wear resistance and cushioning; high-manganese steel screen plates withstand extreme impacts; modular screen plate design facilitates localized replacement; buffer feeders evenly distribute material to reduce impact; optimized vibration parameters (amplitude, frequency) reduce impact force.

Screen accuracy does not meet standards:

Issue: Insufficient material layering, fine-grained materials failing to effectively pass through the screen, or coarse-grained materials mixing with fine materials, affecting product quality.

Solution: Precisely match screen mesh aperture and shape; optimize material dispersion using the uniform forward trajectory of a Linear Vibrating Screen or the involute motion of a Gyratory Vibrating Sieve; control material layer thickness to ensure adequate contact with the screen; increase screening area or use multi-layer screens to simultaneously produce different particle sizes.

Dry mortar

Dry mortar Dolomite

Dolomite Perlite

Perlite Silica Sand

Silica Sand

Unstable equipment operation and excessive vibration:

Issue: Loose equipment foundations, unbalanced excitation forces, or damaged bearings cause abnormal vibration and noise.

Solution: Reinforce concrete foundations with rubber vibration-damping springs or composite vibration-damping pads to absorb vibration; regularly tighten bolts and perform bearing lubrication maintenance; select dynamically balanced exciters; install online vibration monitoring sensors for fault warning.

Difficulty in screening high-moisture materials (dewatering/de-mediuming):

Issue: Wet, sticky materials tend to form clumps, have poor permeability, and create a mud layer on the screen surface, preventing effective separation of solids and liquids or medium.

Solution: Use wedge wire screens or slotted screens to accelerate liquid-solid separation; increase the screen surface angle to promote gravity drainage; use high-frequency vibration from a powerful linear vibrating screen to break down the slurry layer; use high-pressure spray nozzles to assist in cleaning residual medium or slurry.

Dust pollution and safety hazards:

Issue: Screening processes generate large amounts of dust, posing health risks to workers and explosion hazards.

Solutions: Fully sealed stainless steel dust-proof covers with flange dust collection interfaces connected to a dust collection system; silicone rubber seals enhance the sealing of critical areas; explosion-proof vibrating motors and explosion-proof control cabinets eliminate the risk of sparks; forced ventilation systems at the worksite reduce dust concentration.

Silica Sand

Silica Sand Oil Fracturing Proppant

Oil Fracturing Proppant Ceramic Sand

Ceramic Sand Perlite

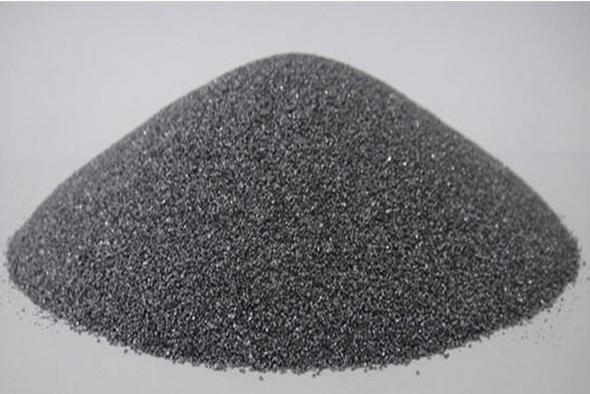

Perlite Metal Silicon Powder

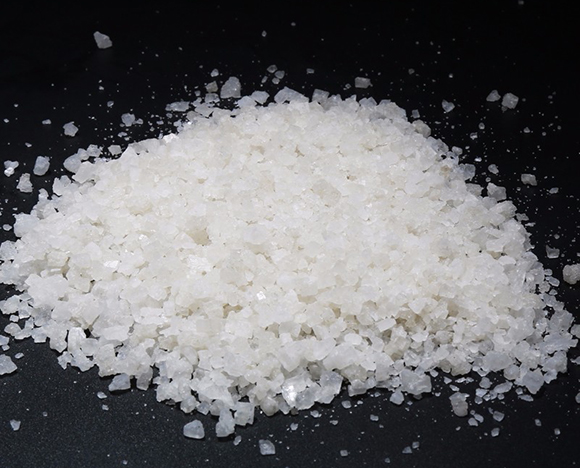

Metal Silicon Powder Industry Salt

Industry Salt Cork powder

Cork powder Calcium Carbonate

Calcium Carbonate Soda Ash

Soda Ash

Understanding these issues and implementing effective solutions is a crucial step toward achieving efficient, safe, and low-cost production in mining operations. Below, we will compare and analyze the advantages of the two main types of screens.

Comparison of Advantages Between Linear Vibrating Screens and Gyratory Vibrating Sieves in the Mining Industry

In the mining industry, Linear Vibrating Screens and Gyratory Vibrating Sieves are the two most widely used types of Ore Gyratory Vibrating Sieves. Although they both fall under the category of vibrating screens, they differ significantly in terms of vibration trajectories, structural characteristics, and applicable scenarios. The following is a comparison table:

| Comparison Dimension | Linear Vibrating Screen | Gyratory Vibrating Sieve |

| Screen Motion Trajectory | Linear reciprocating motion | Near-planar gyratory motion – horizontal projection of circular motion |

| Typical Material Suitability | Medium-fine dry granules, free-flowing bulk, large lump sizing | Fine powders, micro-granules, light-density materials, fragile crystals, sticky/wet or blinding-prone materials |

| Processing Capacity | High – Ideal for large-volume coarse particle separation | Medium-High – High throughput per unit area, especially for precision grading |

| Grading Precision | Good – Suitable for standard accuracy requirements | High – Unique motion enhances dispersion and near-mesh particle penetration |

| Equipment Height | Lower – Compact structure for easy integration/maintenance | Higher – Multi-deck designs common, increasing overall height |

| Maintenance Focus | Vibration motor bearings lubrication, screen mesh tension monitoring | Drive mechanism (eccentric blocks/geared exciters), rubber spring suspension integrity checks |

The above table shows the Ore Gyratory Vibrating Sieve that should be used in different work scenarios. If you are unsure about how to select the right one, please contact us immediately to obtain a customized solution!

Typical application scenarios for the Ore Gyratory Vibrating Sieve

| Scenario | Problem | Solution |

| Dry Screening of Iron Ore | High abrasion causing frequent screen mesh replacement | Linear Vibrating Screen + High-Chromium Alloy Screen Panel + Box-type Exciter |

| Desliming Screen in Coal Plant | Sticky and wet coal slime blocking holes, low efficiency | Gyratory Vibrating Sieve + Elastoplastic Cleaning Device + Inclination Angle & Frequency Adjustment |

| Fine Screening of Quartz Sand | Insufficient precision for 200 mesh (0.074mm) | Gyratory Vibrating Sieve + Ultrasonic Cleaning System + Multi-Layer Stacked Screen Design |

| Pre-screening before Crushing in Large Open-pit Mine | Large ore blocks impacting and damaging structural parts | Linear Vibrating Screen + High-Manganese Steel Grizzly Bars + FEA-Reinforced Cross Beam |

Conclusion:

Through the above content, I believe you now have a basic understanding of the Ore Gyratory Vibrating Sieve. You also know the common problems and solutions in mining industry production. We are a manufacturer with over 30 years of experience in vibrating screening. If you have any needs or questions in this area, please contact us now. We have a professional team to serve you and provide the latest solutions.