The linear swing vibrating screen is an optimized design that combines the dual advantages of the linear vibrating screen and the rectangular gyratory sifter. It has the characteristics of a small footprint, large output, and compact structure. This model is preferred in a space-constrained operating environment.

- Model: FYBS-1536/FYBS-2040

- Mesh Size: 2-100 mesh

- Capacity: 0.5-20 ton/h

- Applicable materials: machine-made sand, silica sand, plate sand, quartz sand, ceramsite sand, calcite, calcium carbonate, bentonite, petroleum coke, mineral powder, etc.

Price: $8500.0 – 11000.0 / Set

Linear Swing Vibrating Screen Machine Introduction

Compared with the linear vibrating screen of the same specification, this equipment can not only fully realize the functions of the vibrating screen in the same space, but also increase the production capacity by 4 to 5 times. It supports 1 to 5 layers of screens and can perform 2 to 6 levels of material classification tasks at the same time. The equipment is widely used in many industrial fields such as chemical industry and new materials, metallurgy, mineral product processing, food processing and abrasives.

Features

Multi-layer grading design, one machine is divided into two groups

One machine is equivalent to multiple machines, which can accurately screen and grade materials of different particle sizes; it is equivalent to the efficiency of multiple ordinary screening equipment, and the output is doubled.

Easy to change the screen, no leakage, and durable

The unique patented mesh frame design has six patents, and the screen does not need to be purchased by our company, and the replacement is autonomous and fast. The mesh frame does not need to be pasted with cloth strips, the screen is durable, and is equipped with a longitudinal tensioning device, which is installed flat and leak-proof.

Patent protection V-belt, strong, durable, and easy to replace

The V-belt connecting the motor and the exciter has a unique design patent. The V-belt is sturdy and durable, and the replacement process is simple and quick. It can be completed only through the belt pressing device, which is both efficient and easy to operate.

Self-disturbance exciter, stable and adjustable

In the field of square swing screens, the exciter makes the screen box angle adjustable and safe and stable with its strong structure and unique self-winding design. Customers can adjust the angle of the whole machine by 4 to 6 degrees according to the different screening accuracy requirements.

Reasonable bracket design, safe and stable

In the design of the linear swing screen bracket, we adhere to the mechanical principle of “four points are the most stable”, use square tube leg design, scientific and simple, and the body is stable and reliable. This is our earliest design and has not been surpassed so far, and users still say it is good.

Large output, low energy consumption, and money saving

The special scientific force-bearing structure not only has a large output, but also, compared with the same model of other manufacturers’ screen machines, a single device can save RMB 10,000 in electricity bills when it works continuously for 24 hours for more than 200 days.

Working Principle

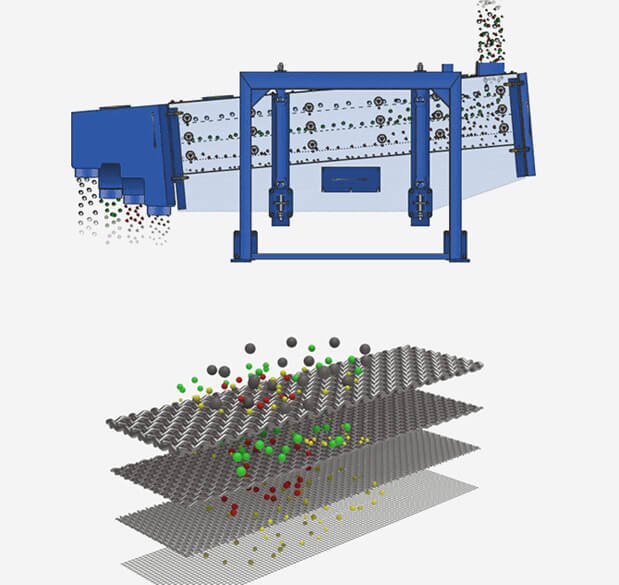

The screening surface of the linear swing vibrating screen machine is usually arranged in a horizontal or slightly inclined state (the inclination range is between 0° and 8°). Compared with the traditional inertial linear vibrating screen, it has higher processing capacity and screening efficiency. After the equipment is started, the screen box performs periodic reciprocating motion in the front and rear directions under the action of inertia, causing the screening surface to swing regularly, guiding the material on the screen surface to perform a planar gyratory motion with the screen box.

During the screening process, materials with a particle size smaller than the size of the sieve hole pass through the sieve hole smoothly and fall to the lower collection area to form the undersize product; while materials with a particle size larger than the sieve hole are discharged from the discharge port after continuous screening, thereby efficiently completing the entire screening process.

Structures

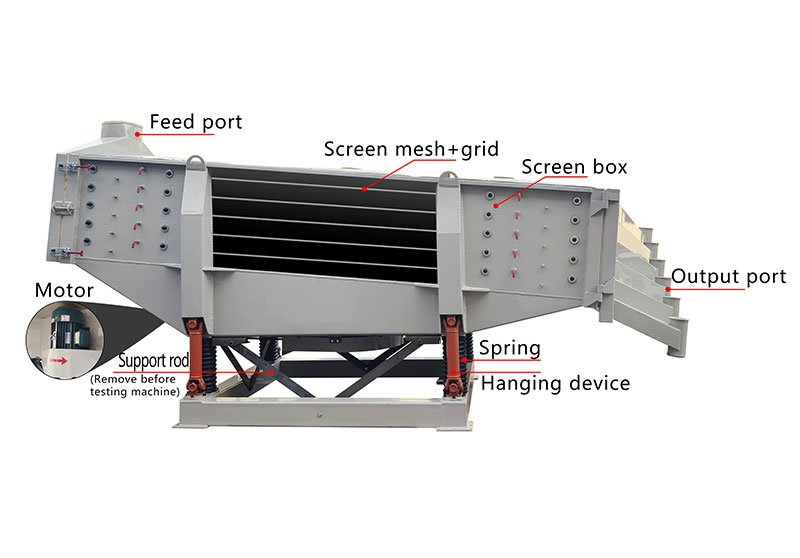

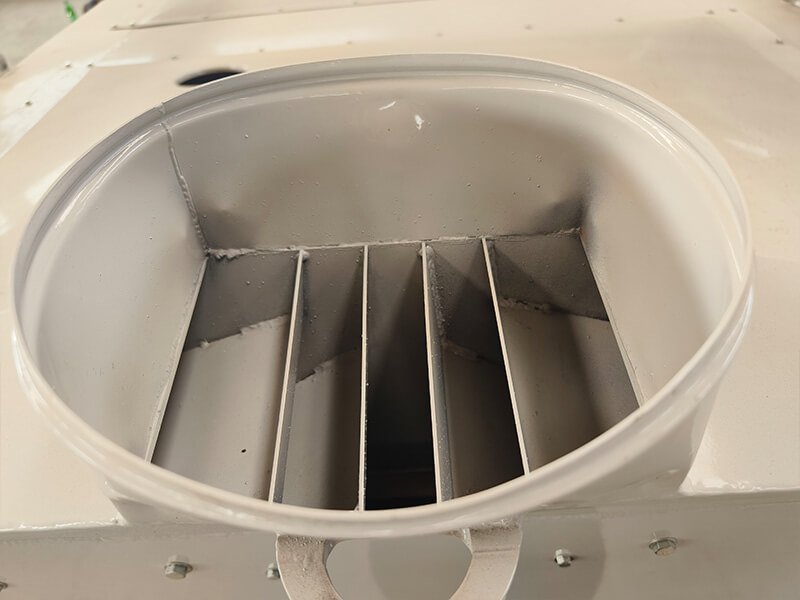

The linear swing vibrating screen machine mainly comprises the feed port, screen box, drive device, screen frame, support frame, vibration reduction device, discharge port, and other components.

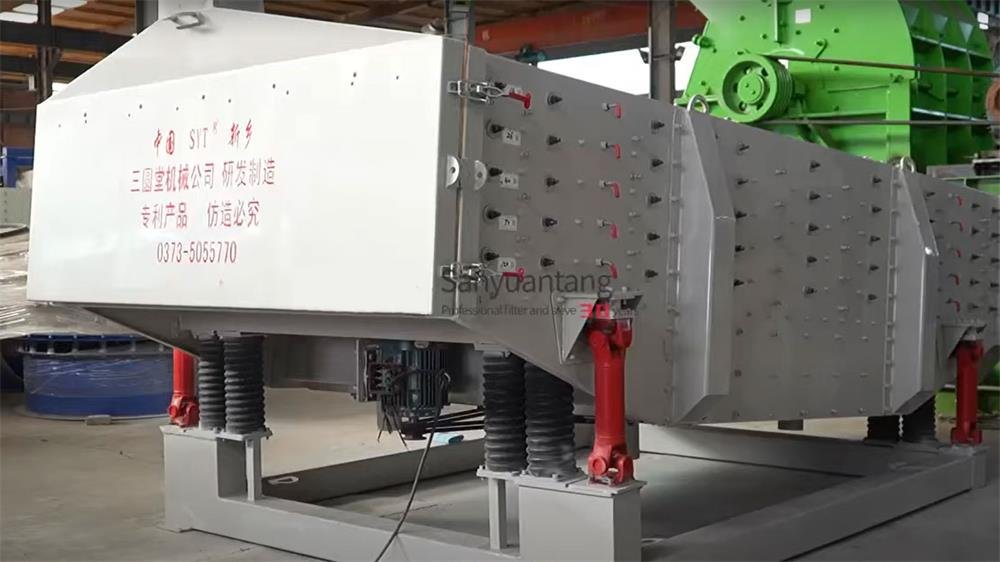

linear swing vibrating screen machine structures

linear swing vibrating screen machine structures

Details

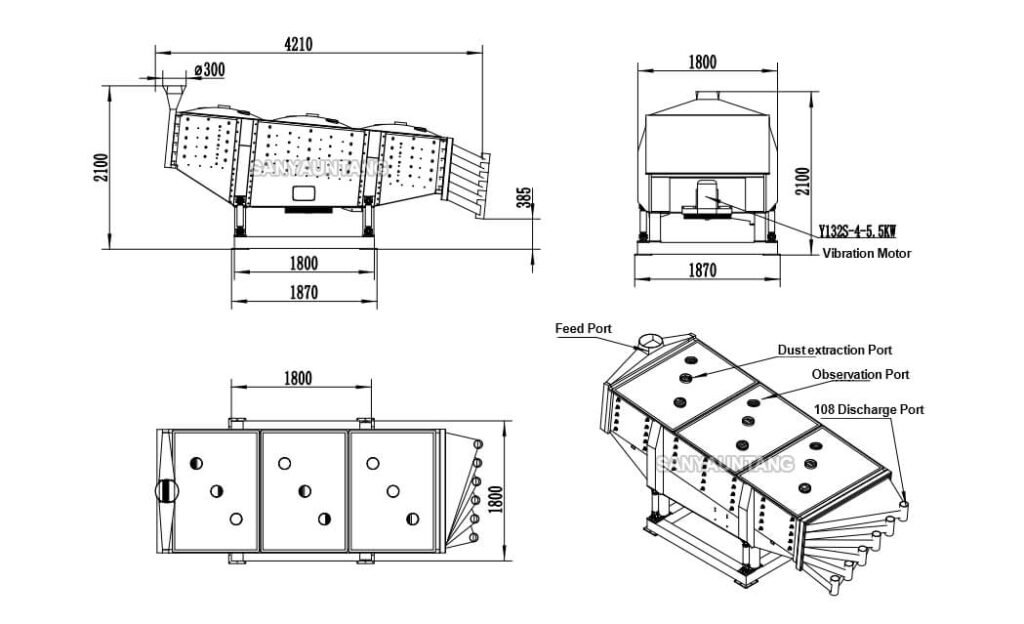

Specifications

| Model | Screen size | Screening area | Screen inclination | Layers | Power | Number of turns | Case travel |

|---|---|---|---|---|---|---|---|

| FYBS1536 | 1.5*3.5 m | 4.5-9 m2 | 5-8 | 1-10 | 5.5 | 180-260 | 25-60 mm |

| FYBS2040 | 2.0*4.0 m | 8-9 m2 | 5-8 | 1-10 | 7.5 | 180-260 | 25-60 mm |

Different Types of Linear Swing Vibrating Screen Machines

Carbon steel linear swing vibrating screen machine

Stainless steel linear swing vibrating screen machine

Application

The linear swing screen is a highly efficient screening equipment. Its unique swing motion and design make it suitable for screening a variety of materials. The following are the types of materials that the linear swing screen is suitable for screening:

- Powder materials: such as chemical raw materials, food additives, drug powders, metal powders, fertilizers, soda ash, resins, starch, milk powder, etc.

- Particle materials: impurity removal and particle size classification of materials such as sand, ore, coal, ceramsite sand, quartz sand, fracturing sand, and gemstone sand.

Dry mortar

Dry mortar Dolomite

Dolomite Perlite

Perlite Silica Sand

Silica Sand

Customize Your Production Line

One-stop customized screening solutions

Send Inquiry Now

China Linear Swing Vibrating Screen Machine Manufacturer

Sanyuantang is a China linear swing vibrating screen machine manufacturer, we have focused on providing whole screening and conveying solutions for 30 years. We have focused on providing integrated screening and conveying solutions. We have extensive customer cases and professional technical team experience. If you want to increase your sand and gravel fine screening capacity, please feel free to contact our team.

non-standard customized

30 years experience

Strict quality control system

Complete after-sales service

Lifetime technical support

Related Equipment

In addition to the linear swing vibrating screen machine, we also produce other types of gyratory screen, and related production line equipment, such as: crushing equipment, belt conveyor, bucket elevator, etc. If you want to purchase related equipment, please feel free to consult us.