Sanyuantang is a vibrating screening machine supplier and manufacturer in China. We have focused on providing whole screening and conveying solutions for 30 years. In terms of screening technology, our equipment has been awarded US patent authorization and more than 40 domestic patent certifications. At the same time, we have also obtained ISO quality management system certification and EU CE safety certification for the international market. Our factory produces a full range of screening machinery products, which are widely used to remove and classify various powder and granular materials. The screening machine can be customized in design and production according to your needs.

Different types of Screening Machines

Inline Vibratory Screen

The feed port and the discharge port are designed in the same vertical direction, with a fast unloading speed and a yield that is 2-3 times that of ordinary vibrating screens. It is especially suitable for the rapid impurity removal process in flour production lines.

Linear Screening Machine

It adopts a dual motor configuration and is suitable for removing impurities from dry powder and granular materials. It can also be used as a conveyor or feeder to transport products over long distances. It is usually used in the early coarse screening process of the production line.

Single Vibration Source Gyratory Screener

It adopts single vibration source configuration, which is cost-effective and is usually suitable for dry sand classification production lines with high precision requirements but small output.

Linear Swing Vibrating Screen Machine

Combining the advantages of linear vibrating screen and square vibrating screen, it occupies a small area, has a large output and a compact structure. It is the preferred model in space-constrained working environments.

Dewatering Vibrating Screen

Used for material dehydration and solid-liquid separation. It mainly removes moisture from materials through the combination of high-frequency vibration and screen mesh,It is widely used in mining, chemical, food, environmental protection, coal and other industries.

Rotary Airflow Sifter

An ultrafine powder screening equipment, which uses airflow and centrifugal force to screen powder materials within 80-530 mesh, is suitable for screening and processing ultrafine powders and special materials with light specific gravity, high viscosity, high fiber content, static electricity, easy aggregation, etc.

High-Frequency Filter Vibrating Screen

Through high-frequency vibration, the solid particles and liquid in the material produce violent relative movement, quickly separating impurities and fine particles. It is usually used for filtering pulp, paint or ceramic glaze slurry.

Bulk Bag Dump Station

The hopper and vibrating screener integrates feeding and screening functions, suitable for manual unpacking of 0~50 kg bagged or barreled powdered materials. Equipped with dust prevention device, widely used in the material feeding process of pharmaceutical, food, chemical and other industries.

Functions of the Vibrating Screening Machine

- Screening: Separate the material through the screen and classify the material into different particle size levels.

- Impurity removal: Remove impurities, foreign matter or unqualified particles in the material.

- Grading: According to the preset particle size standard, the screening machine accurately classifies the material.

- Filtration: Intercept suspended particles, impurities or solid particles in the liquid, purify and filter the liquid or slurry.

Videos

Ultrasonic Vibrating Screen for Powder Screening

Rotary Vibrating Screen for Liquid Screening

Tumbler Screen for Flour Screening

Large Capacity Sand Screening Machine

Sand and Gravel Screening Machine

Sand and Gravel Screening Machine

Customize Vibrating Screening Machine

One-stop customized screening solutions

Send Inquiry Now

Application

The vibratory screening machine is mainly used in the following industries and materials

- Common application areas and application materials

- Food processing: flour, powdered sugar, spice, starch, coffee, condiments, juice, liquid, slurry and other materials.

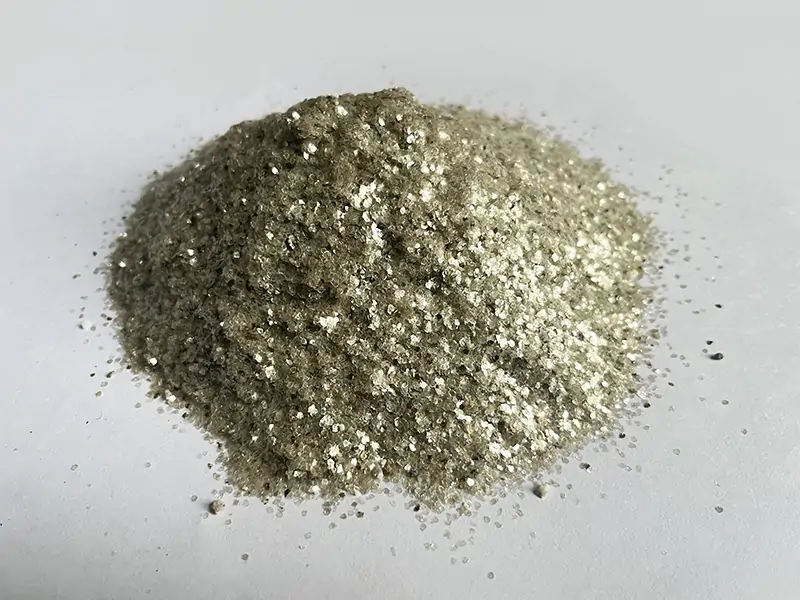

- Mining and metallurgy: screening and grading of mineral powders such as quartz sand, fracturing sand, machine-made sand, mica powder, brown corundum, calcium carbonate, granite, limestone, bentonite, metal powder, etc.

- Chemicals: coatings, plastic particles, polyethylene, fertilizers, chemical raw materials, etc.

- Medicine: tablets, raw materials, Chinese medicine powder, etc.

- Manufacturing: sawdust, wood blocks, wood chips, shavings, etc.

- New energy: graphite materials, battery negative electrode materials, biomass fuels, etc.

Food

Food Wheat Flour

Wheat Flour Tapioca Flour

Tapioca Flour Soy milk

Soy milk Palm Oil

Palm Oil Pharmaceutical

Pharmaceutical Quartz sand

Quartz sand Mica Powder

Mica Powder Petroleum Coke

Petroleum Coke Metal Silicon Powder

Metal Silicon Powder Lithium manganate

Lithium manganate Wood chips

Wood chips Sawdust

Sawdust Plastic Particles

Plastic Particles Powder coating

Powder coating