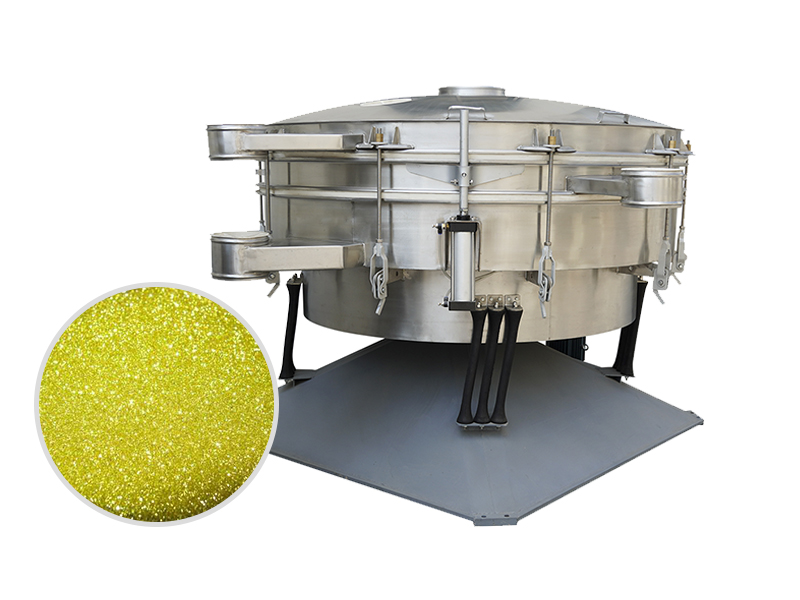

Tumbler screening machine, also known as a tumbler screener, is a type of screening machine used to separate materials based on their particle size. It operates on a unique principle called “gyratory motion” or “gyration,” which is different from traditional vibrating screens. The tumbler screen is commonly used in industries such as food processing, pharmaceuticals, chemicals, and minerals.

Tumbler Screening Machine Working Principle

Tumbling Action

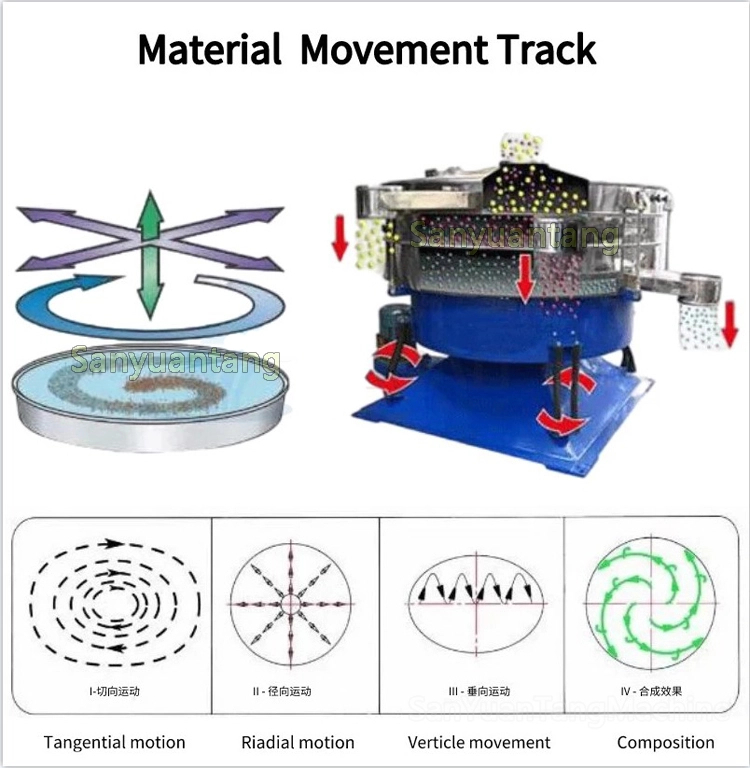

The core principle of a tumbler screening machine is its tumbling or gyratory motion. The screen is set at a slight horizontal tilt and is mounted on springs or other suspension systems. When the machine is in operation, it gyrates or tumbles in a circular motion.

Feed Material

The material to be screened is introduced onto the center of the screen or into a feed inlet. This material can be a mixture of different particle sizes, and the goal is to separate them into different size fractions.

Sieve Decks

Tumbler screeners typically have multiple sieve decks or layers. These decks are stacked on top of each other, and each deck contains a mesh screen with openings of a specific size.

Screening Process

As the machine gyrates, the material is subjected to a combination of horizontal and vertical movements. This tumbling action causes the particles to stratify or layer based on their size. Larger particles tend to move to the top and outer edges of the screen, while smaller particles settle closer to the center and bottom.

Separation

As the material moves across the screen’s surface, particles that are smaller than the openings in the mesh screen fall through the openings and onto the lower decks or collection points. Larger particles that are unable to pass through the openings continue to move along the screen’s surface until they reach an appropriate discharge point.

Multiple Fraction Separation

The multiple decks in a tumbler screen allow for the separation of material into several size fractions. Each deck may have a different mesh size to achieve the desired particle size separation.

Discharge

Once the material reaches the desired separation level, it is collected and discharged from the respective collection points on the screen.

Key Benefits of Tumbler Screening Machine

- High Screening Efficiency: The tumbling motion of the material, combined with the varying screen panel angles, allows for the effective separation of particles. This results in high screening efficiency, ensuring accurate particle size classification and removal of oversized or undersized materials.

- Gentle Screening: Tumbler screening machines are designed to handle delicate or fragile materials without causing damage. The tumbling action prevents excessive agitation, reducing the risk of material breakage or degradation during the screening process.

- Versatility: Tumbler Screens are capable of handling a wide range of materials, from fine powders to granular materials. They can effectively screen materials with difficult-to-separate particle sizes, shapes, or properties, making them suitable for diverse industrial applications.

- Reduced Noise and Dust Emissions: Tumbler Screens are engineered to minimize noise levels and dust emissions. This makes them ideal for applications that require a clean and quiet screening environment, promoting a safer and more comfortable working environment for operators.

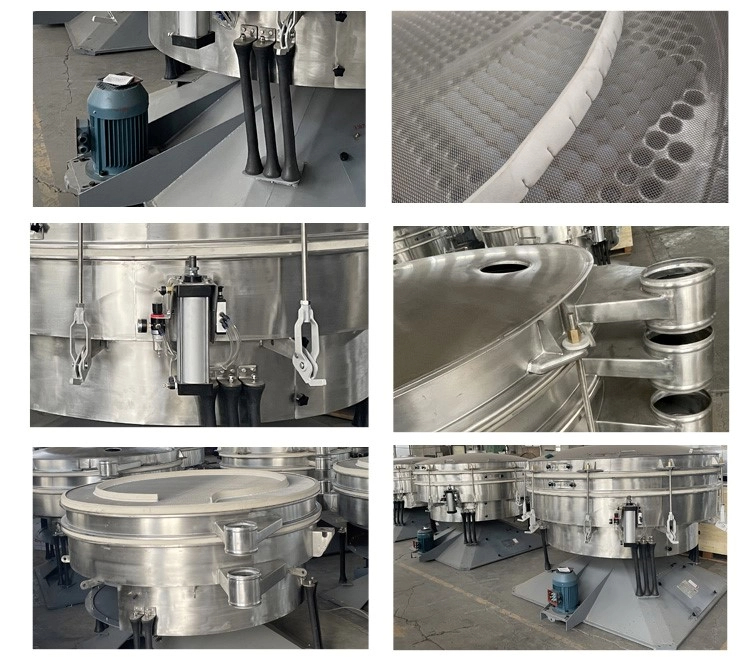

- Easy Maintenance and Cleaning: Tumbler Screens are designed for easy maintenance and cleaning. The drum can be easily removed or opened, providing convenient access to the screen panels for inspection, replacement, or cleaning purposes. This ensures minimal downtime and optimal operational efficiency.

Advantages of Tumbler Screen

- Gentle screening

The tumbling action is less aggressive than traditional vibrating screens, making it suitable for fragile or delicate materials. - High accuracy

Tumbler screens can achieve high screening accuracy due to the stratification of particles. - Multi-deck separation

Multiple decks allow for efficient separation of materials into different size fractions.

Details Show

Limitations

Lower throughput: Tumbler screens may have a lower processing capacity compared to other screening methods.

Space requirements: The gyratory motion and multiple decks can result in a larger machine footprint.

Sanyuantang Machine is a professional manufacturer of screening machines and conveying equipment. Our products mainly include drum screens, rotary vibrating screens, gyratory screens, and vibrating screw elevators. If you have any questions, please contact us at: info@sanyuantang.com, and we will provide you with the most suitable screening solution and price.