In the field of screening equipment, SanYuantang Machinery, with its excellent technology and extensive product line, offers a variety of efficient screening solutions, including the square gyratory screen (also known as the swing vibrating screen) and the circular tumbler screen. How to choose the appropriate square gyratory screen and round tumbler screen? You can refer to the following suggestions.

Square Gyratory Screen

Square Gyratory Screen Circular Tumbler Screen

Circular Tumbler Screen

Differences In Working Principle

Square Gyratory Screen

Sanyuantang’s square gyratory screen utilizes a unique drive device, generating an inertial force that changes regularly around a fixed axis. This is primarily due to the rotation of the eccentric wheel around the fixed axis, forming a reciprocating inertial force, thereby achieving material screening.

Circular Tumbler Screen

The circular tumbler screen simulates the low-frequency rotational movement of manual sieving. Its instantaneous movement is a combination of radial displacement and circular motion around this displacement. This design makes the screening process gentler and more efficient.

Material Adaptability

Square Gyratory Screen: It is widely applicable in industries such as chemicals, metallurgy, mining, feed, and food. It is particularly adept at handling various materials such as sand powder, carbon, heavy alkali, salt, resin, compound fertilizer, large and small particles of urea, and feed.

Ceramic Sand

Ceramic Sand Silica Sand

Silica Sand Oil Fracturing Proppant

Oil Fracturing Proppant

Circular Tumbler Screen: It is also suitable for multiple industries like chemicals, pharmaceuticals, food and spices, tea, feed, plastics, and rubber, particularly excelling in the grading of fine materials.

Starch

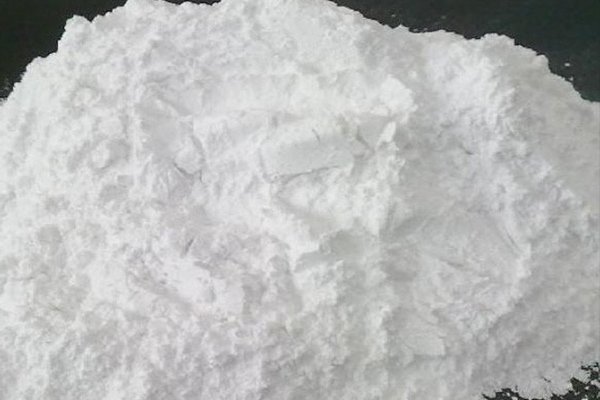

Starch Light Calcium Powder

Light Calcium Powder Paint Coating

Paint Coating

The choice should be made based on the specific nature and requirements of the materials.

Screening Precision Consideration

Square Gyratory Screen: For materials below 300 mesh, SanYuantang’s square gyratory screen can provide excellent screening results. Its unique screening mechanism allows materials to vertically enter the screen surface and settle smoothly, enhancing screening efficiency.

Circular Tumbler Screen: With its design mimicking manual screening actions, Sanyuantang’s circular tumbler screen can effectively handle materials below 600 mesh, meeting the needs for higher precision screening.

SanYuantang’s square gyratory screen and circular tumbler screens have unique advantages and applicable ranges. The better choice depends on your specific needs, including the nature of the material, the required screening precision, and the production environment.

As a professional screening equipment manufacturer, Sanyuantang can provide you with customized solutions and high-quality product selections to help you achieve efficient screening effortlessly. For more information on our Large Capacity Vibrating Screen and other products, don’t hesitate to get in touch with us to get the product catalog and factory quotation.