Highly efficient vibrating screen separator for sifting wet or dry materials

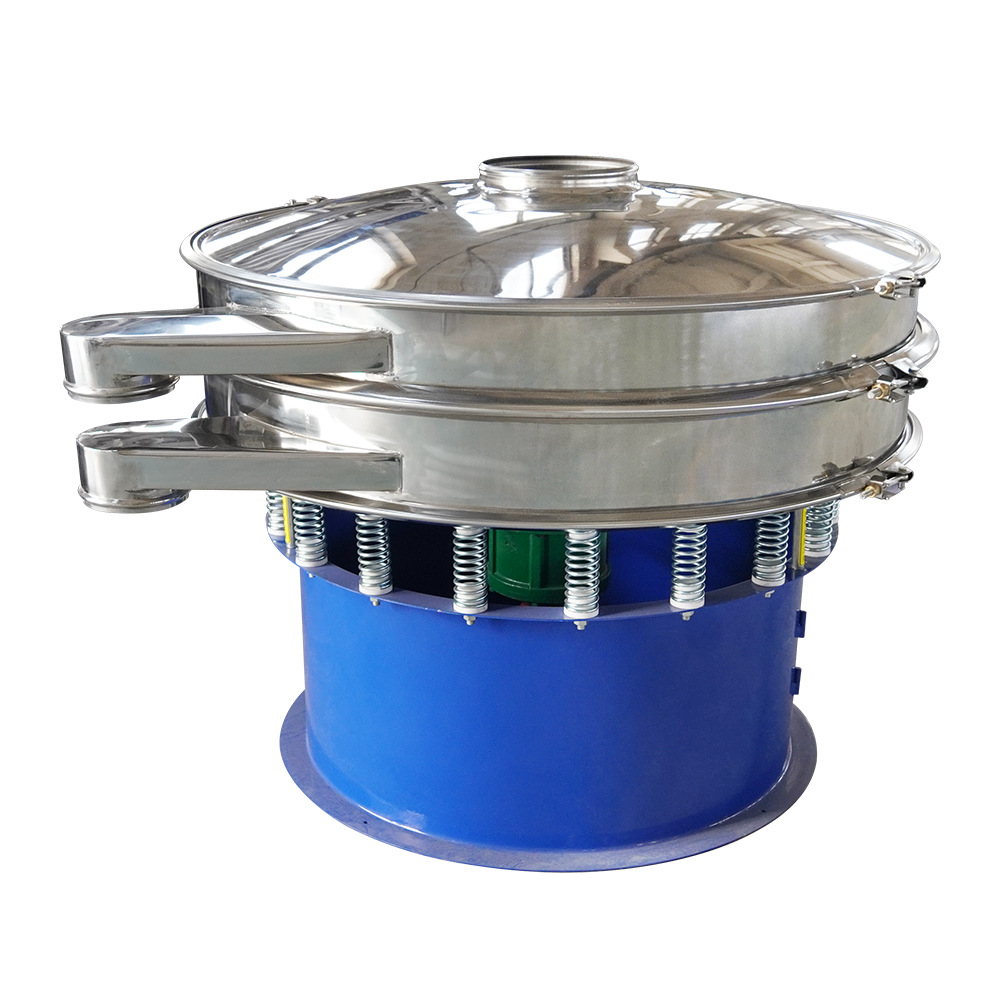

The vibrating screen separator is a circular rotary vibrating screen, also known as a vibro sifter. Primarily used to screen dry powder, granular products, wet products, and liquids, it provides excellent separation and screening solutions for industrial applications. The vibrating screen separators are available in 1-5 deck screen configurations in a variety of sizes and designs to meet any throughput requirement.

Contact us! Our team is ready to help you find the right screening solution for your specific needs.

- Model: SY-600/800/1000/1200/1500/1800 mm

- Material: Stainless Steel 304/316/Carbon Steel

- Mesh Size: 5-500 mesh

- Layers: 1-5 layers

- Motor Power: 0.25-3 kw

- Capacity: 100Kg – 3 Tons/hour

- Customized: Acceptable

Price: $799 – $3999 /Set

Application

Food industry

Wheat flour, sugar powder, starch, salt, rice flour, milk powder, spice powder, soybean, egg powder, palm oil, soy sauce, fruit juice.

Chemical industry

Resin, coating, industrial drug, cosmetics, paint, and so on

Pharmaceutical industry

Drug powders, such as Chinese medicine powder, Chinese medicine granules, pills, Western medicine powder, raw materials, starch, dextrin, etc.

Metal metallurgy mining

Aluminum powder, lead powder, copper powder, ore, alloyed powder, ti powder, kaolin, lime, quartz sand, etc.

Pollution treatment

Waste oil, waste water, dyeing wastewater, auxiliaries, activated carbon, etc.

Wheat Flour

Wheat Flour Milk Powder

Milk Powder Oil Fracturing Proppant

Oil Fracturing Proppant Grain Pellets

Grain Pellets Medicine Powder

Medicine Powder PP/PE Granules

PP/PE Granules Paint Coating

Paint Coating Metal Powder

Metal Powder Emery

Emery

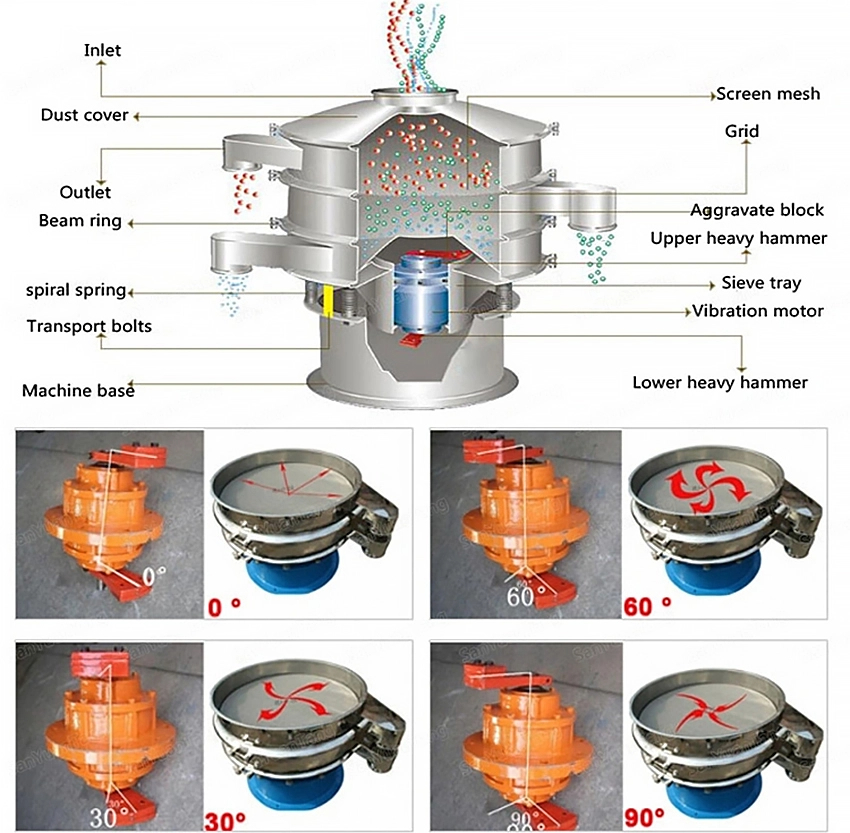

Vibrating screen separator Working Principle

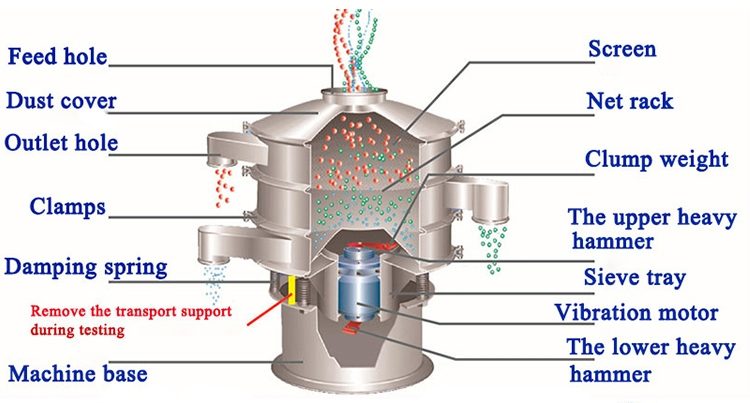

The principle of vibratory screen separator is to use the heavy hammer installed above and below the motor shaft (unbalanced hammer) to transform the rotary motion of the motor into horizontal, vertical, and inclined three-dimensional motion, and then transfer this motion to the screen surface, so that the material does the outwardly expanding involute motion on the screen surface.

The vibrating separators have the advantages of long trajectory of material running and a high utilization rate of the screen surface. By adjusting the phase angle of the upper and lower hammers, the trajectory of the material on the screen surface can be changed. It can be used for fine screening and probability screening of materials.

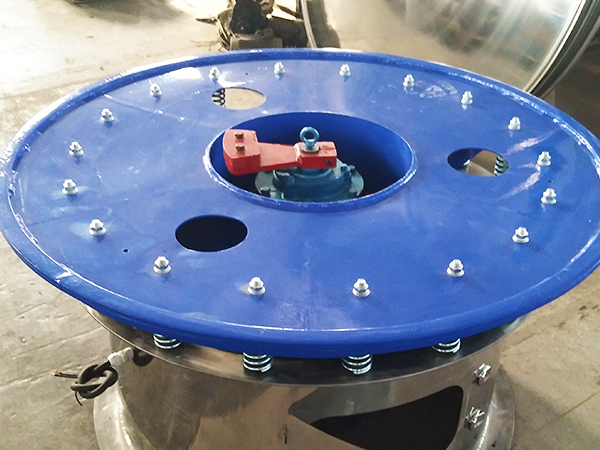

Main components:

- Drive base with motor or electromagnetic vibrator

- Sieves.

- Single or multiple circular screen frames with lateral outlets

- Dust cover with inlet

- Elastic support components

Details Show

Dust cover with inlet

Dust cover with inlet Outlet

Outlet Screen frame

Screen frame Gate

Gate Damping springs

Damping springs Drive base with motor

Drive base with motor

Specifications

| Model | Layer (s) | Granularity (mm) | Sieve Mesh | Effective Diameter (mm) | Power (KW) | Capacity(Kg/h) |

|---|---|---|---|---|---|---|

| SY-XZS400 | 1-3 | <20 | 2-500 mesh | 380 | 0.25 | 100 |

| SY-XZS600 | 1-3 | <20 | 3-500 mesh | 580 | 0.55 | 200 |

| SY-XZS800 | 1-5 | <30 | 3-500 mesh | 780 | 0.75 | 500 |

| SY-XZS1000 | 1-5 | <30 | 3-500 mesh | 970 | 1.1 | 800 |

| SY-XZS1200 | 1-5 | <30 | 3-500 mesh | 1170 | 1.5 | 1200 |

| SY-XZS1500 | 1-5 | <50 | 3-500 mesh | 1470 | 2.2 | 1500 |

| SY-XZS1800 | 1-5 | <50 | 3-500 mesh | 1770 | 3.0 | 2000 |

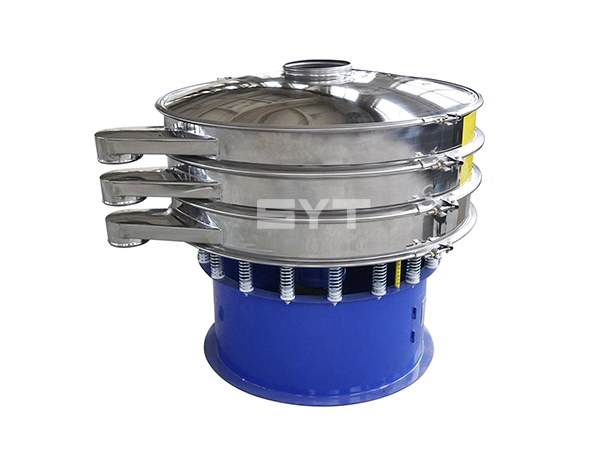

One-Layer

Two Layers

Three Layers

Four Layers

Custom according to Your Needs

The vibratory separator machine is available in 3 materials: stainless steel, carbon steel, and plastic to meet the screening needs of different industries.

The standard vibrating screen machine body and material contact part are made of selected 304 stainless steel, and the machine base part is made of carbon steel. The whole machine can also be made of stainless steel according to user requirements (stainless steel vibrating screen), as well as a plastic vibrating screen designed for special chemical materials. In addition, according to the screening grade of the material, you can choose to customize a single or multi-layer screen, as well as add an ultrasonic device.

Contact Part Stainless Steel + Carbon Steel

Full Stainless Steel

Carbon Steel

Anti Corrosion Plastic PP

Vibrating screen separators with allowable production capacity from 100 to 3300kg/h are widely used for screening and filtering of granular, powdery, and viscous materials, including food, feed, plastic particles, ceramic powders, metal powders, and can be fully customized according to your application requirements. Such as gate type, add edge type vibrating screen, and so on.

Add hopper

Add scraper

Extended feed port

Open type

Features

- Used for a variety of particles, powders, and slimes can be screened within a certain range.

- Screening as fine as 600 mesh or 0.02mm, filtration as small as 5 microns.

- Graduated screening, optional 1-5 layers of screen, can be 2 to 6 levels of screening or filtration at the same time.

- Compact and durable design, easy to operate and clean.

- Vibrating screen separator impurities, coarse material automatically discharged, and can be continuously operated.

- Mesh frame design, screen mesh used for a long time, change the mesh quickly, only 3-5 minutes.

- Small size, space-saving, easy to move, the direction of the outlet can be adjusted, coarse and fine materials are automatically discharged and can be automated or manually operated.

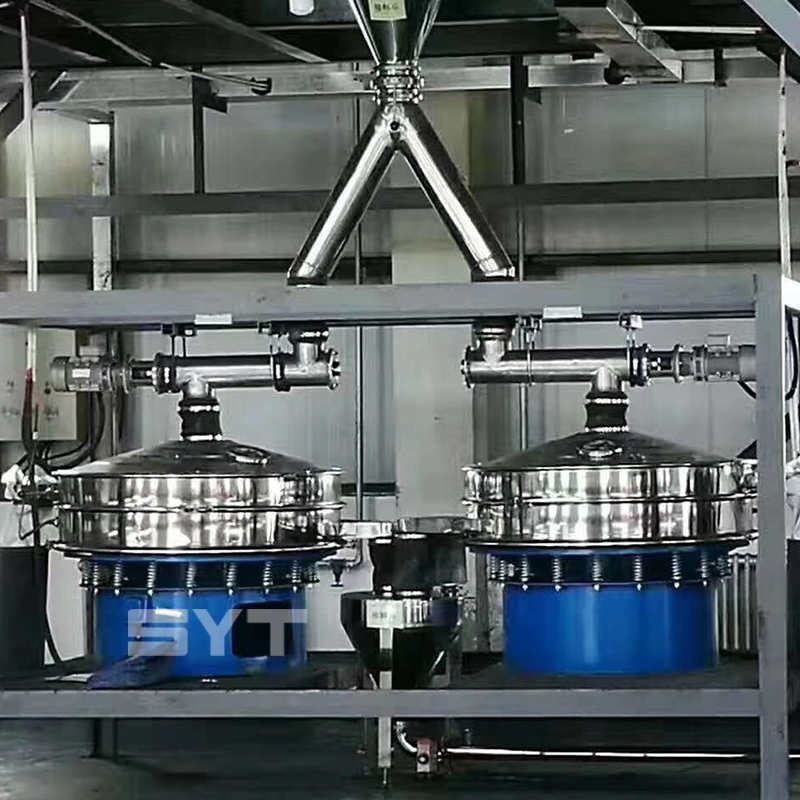

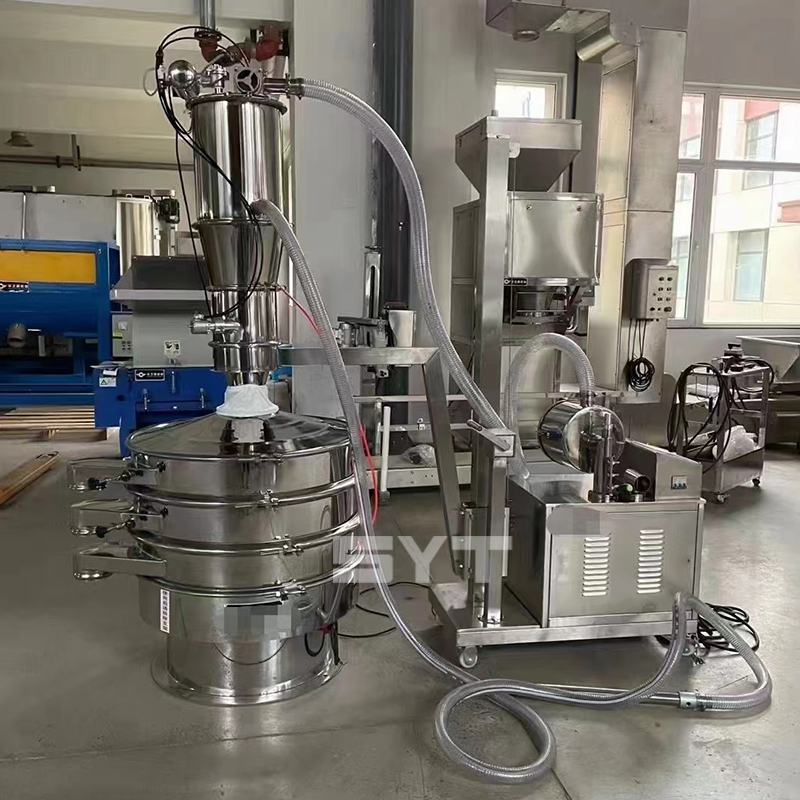

Customer Site

Angle Adjustment Of The Vibrating Screen Separator

1. Change the phase angle of the upper and lower hammers can change the trajectory and residence time of the materials on the screen, to make the vibrating screen separator adapt to the separation state required by various materials, such as the distribution of materials, processing capacity, separation efficiency, over the net rate and other changes, it should be adjusted to a good state.

2. The circular vibrating screen separator on the hammer can not adjust the angle, open the bottom bucket adjustment hole, loosen the lower hammer fixed bolt, according to the screening material trajectory, to the discharge port in the opposite direction to adjust the phase angle of the upper and lower hammers, and then a small amount of material placed on the top of the screen mesh, so that the sieve machine running, do screen material trajectory check, such as processing parameters have reached a good effect, shut down on the tightening of the fixed bolts, the end of the adjustment.

Sometimes due to the specific gravity of the material, humidity, the other side of the tilt angle, and other parameters, the phase angle can not be adjusted successfully, so you need to be patient and adjust again so that the vibrating screen separator play the application of high efficiency.

3. Adjustment of additional weight: there are additional weights on the side of the upper and lower weights, its role is to increase the excitation force of the vibrating screen separator, according to the number of layers of different sieve machines, the specific gravity of the material to increase or decrease the excitation force, and increase or decrease the number of additional weights to make the screen vibration separator to achieve a good sieving effect.