How to Solve Static Problems in Vibratory Screen Separator Systems?

How to Solve Static Problems in Vibratory Screen Separator Systems? Learn practical grounding, ultrasonic, and anti-static solutions for stable production.

How to Solve Static Problems in Vibratory Screen Separator Systems? Learn practical grounding, ultrasonic, and anti-static solutions for stable production.

Explore the main types of sieves, their applications in labs, food, pharma, and industry, and expert tips for choosing the right sieve.

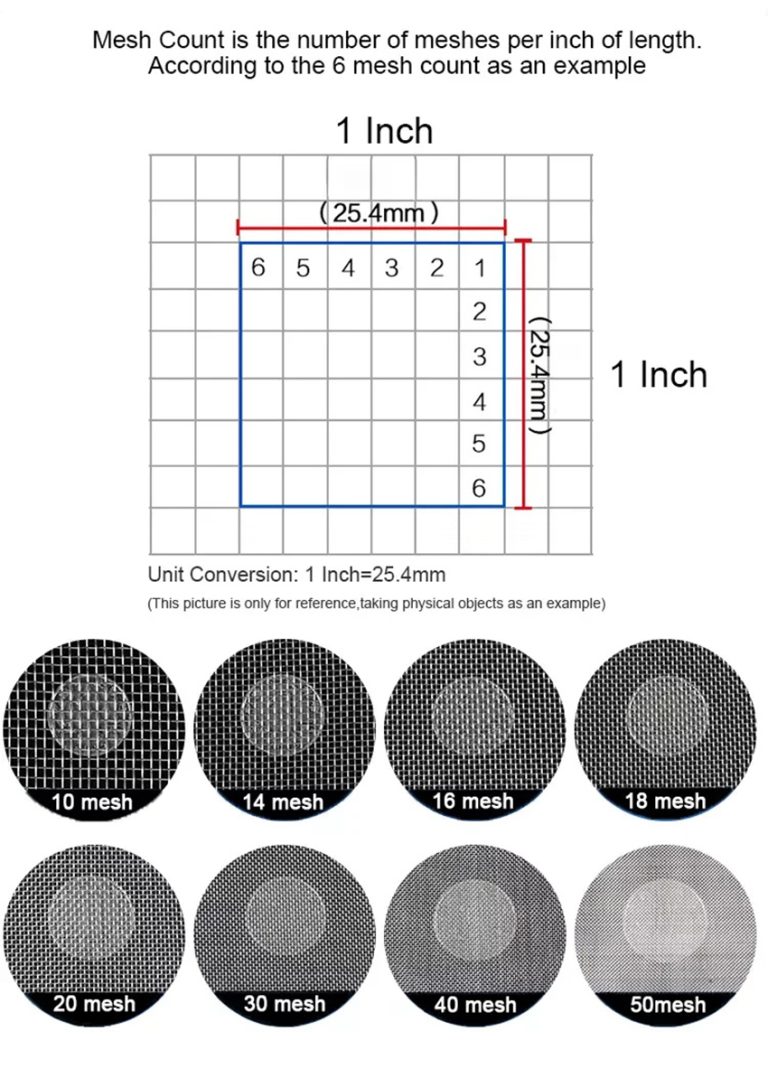

A practical vibrating screen mesh size chart explaining pore size, mesh number, and how to select the correct screen.

This guide compares mulch and wood chips in terms of composition, lifespan, and applications, and explains how wood chip screeners ensure consistent, high-quality results for landscaping and production.

Pharmaceutical Screening Equipment for powders granules and extracts helps improve particle separation product purity and production efficiency.

Vibrating screen springs including steel wire, rubber, and composite types. Learn features, applications, and selection tips for industrial vibrating screens.

This practical Vibrating Screen Troubleshooting guide helps operators quickly identify causes and repair methods for common failures, improving screening efficiency and preventing repeat breakdowns.

Overview of different vibrating screens and prices, including circular, tumbler, gyratory, and linear types, with capacity, mesh size, and cost factors.

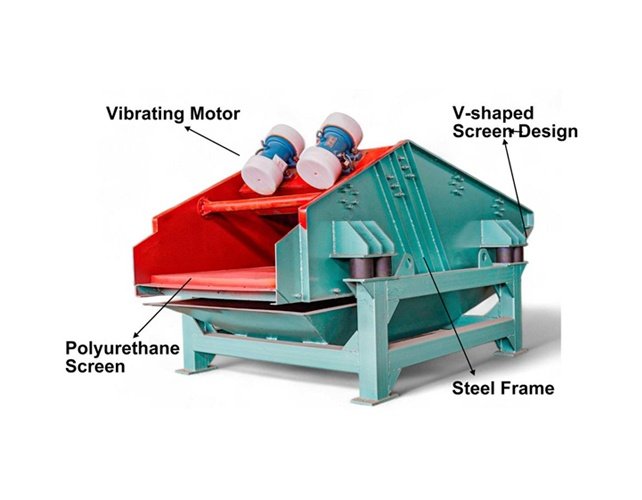

This article explains vibrating screen spare parts including excitation system load bearing system screening system and support system. It covers key component functions differences and maintenance tips and supports spare parts replacement and customization.

Selection of vibrating screen requires accurate material data. This article explains how material properties affect screening accuracy, capacity, and safety.

This guide explains common sieving machine types, working principles, applications, mesh ranges and capacities to help engineers select efficient screening solutions.

ultrasonic vibrating screen replacement process for ball cleaning vibrating screens, covering size confirmation, system matching, opening position, seal ring and fixture updates for engineers.

We provide industrial sieves and vibrating sieve solutions with over 30 years of manufacturing experience. Our factory offers large, small, stainless steel, multi-layer, and high-capacity sieves for food, pharmaceutical, chemical, construction, and mining industries, ensuring efficient screening, precise grading, and stable operation.

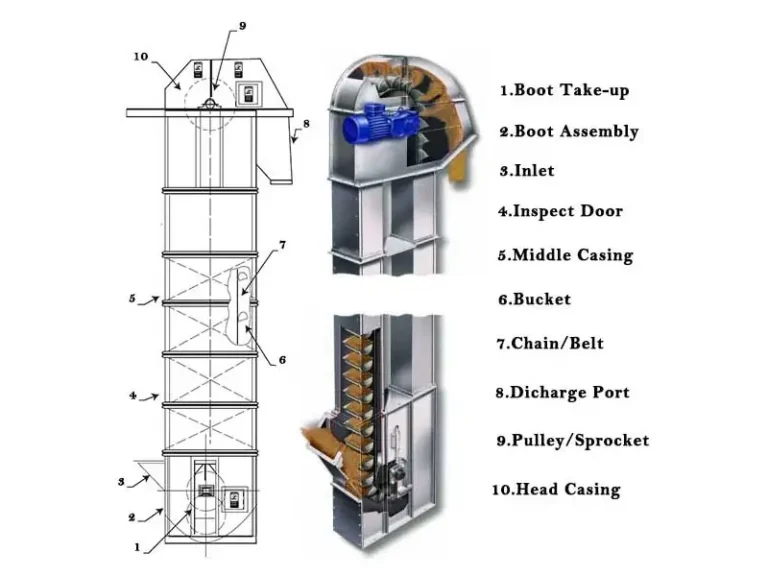

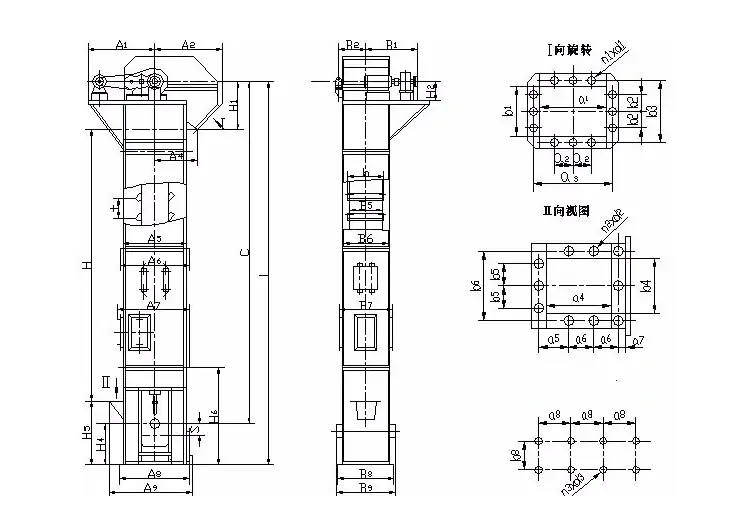

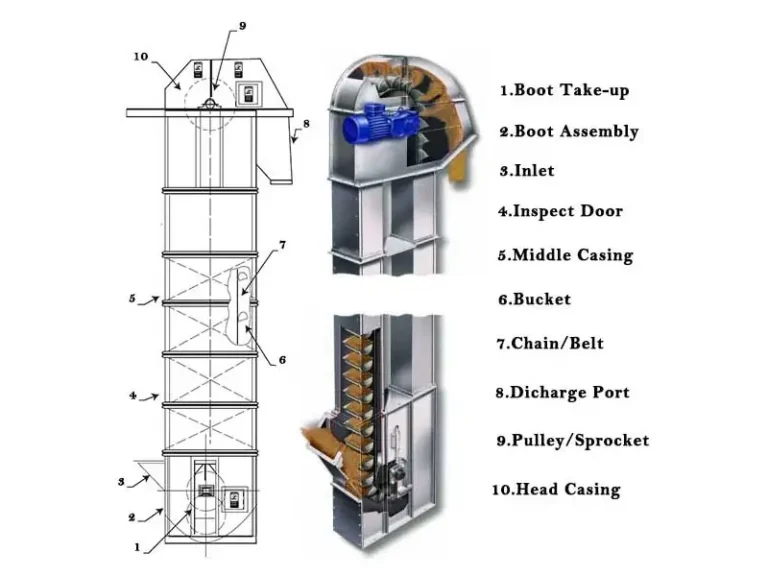

Our bucket elevators efficiently lift grains, powders, sand, cement, and clinker, with TH series models offering 19–540 m³/h capacity and handling material sizes 20–100 mm. Suitable for sand production, rice mills, cement plants, and chemical industries, they provide high efficiency, compact design, and reliable operation. We offer belt, chain, and paddle types, plus customized solutions and complete production line integration. With over 20 years of experience, we deliver durable, low-maintenance, and tailored vertical material handling solutions.

Learn the main types of industrial screeners — ultrasonic, linear, rotary, and inclined screens. Discover how each type works and find the right solution for your industry.

An Ore Gyratory Vibrating Sieve is a primary piece of equipment used in the mining industry for material classification, dewatering, de-mediation, and desliming operations.

A dewatering vibrating screen is used in sand production lines to remove excess water, recover fine sand, and ensure stable downstream processing.

Learn how to choose the right vibration screen to improve accuracy, capacity, stability, and efficiency. High-quality screening solutions from Sanyuantang.

As a leading linear vibrating screen manufacturer, Sanyuantang sp…

Learn how to choose the right vibration screen to improve accuracy, capacity, stability, and efficiency. High-quality screening solutions from Sanyuantang.

Rotary vibrating screens and tumbler screening machines (also kno…

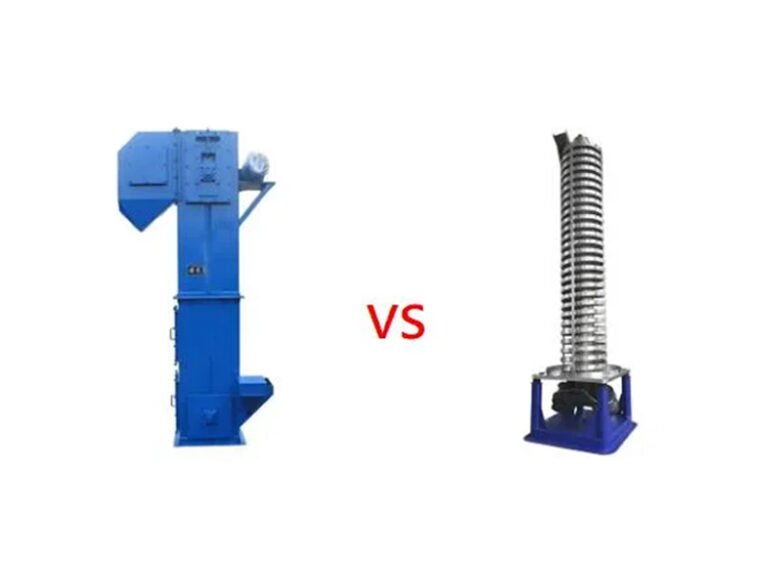

Among all vertical conveying solutions, the vibrating spiral elev…

The circular tumbler screen is a material screening device that m…

The Fully Balanced Square Gyratory Vibrating Screen Machine is a …

What is an Inline Sifter? Inline Sifter is a kind of screening eq…

Is your yeast production line facing challenges like screen …

The linear vibrating screen machine, as a critical piece of equip…

With corrosion resistance, high strength and durability, 304 stai…

Standard test sieve, also known as test sieve machine or analytic…

How to separate a solid from a liquid is a common question in man…

In the production and recycling processes of the plastics industr…

In wood processing, panel manufacturing, and the biomass energy i…

Within the contemporary aggregates industry, demand for sand and …

This mini vibrating screen is a compact, high-efficiency small-sc…

The proper installation methods and precautions for dewatering sc…

Stainless steel mesh strainers are the most common type of mesh s…

Double Decker Screen Compared to single-deck vibrating screens, d…

In carbon industry production, the screening of materials such as…

Mobile conveyor belts are indispensable equipment across industri…

What is a Large Vibrating Screen? A large vibrating screen is a h…

In modern industrial production, material screening plays a cruci…

We provide this FAQ for Ultrasonic Sieve Shakers to help you achi…

Ultrasonic sieve shakers are now widely used across various indus…

In industries such as food processing, chemical engineering, and …

In the modern food processing industry, flour quality is a critic…

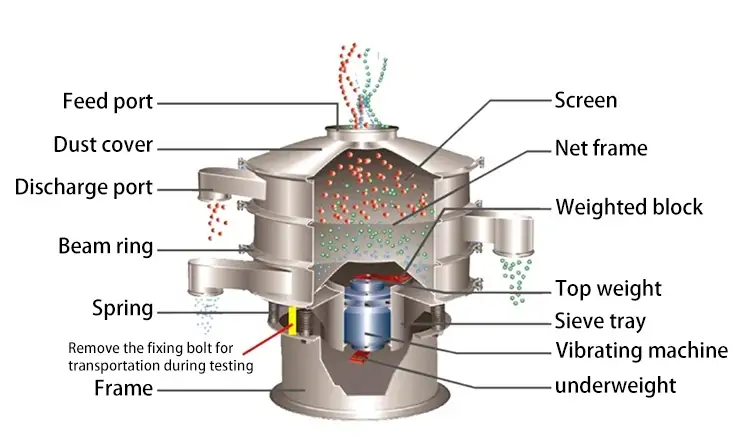

A rotary vibrating screen is a common circular screening device. …

We are a leading manufacturer of vibrating screens in China’…

What is the amplitude of a vibrating screen? The amplitude of a v…

By now, many of you are likely familiar with the applications and…

what is a screw conveyor Screw conveyors are conveying devices po…

A screw conveyor is a conveying and transportation device driven …

In the solid material screening industry, there are two highly ef…

A large-inclination swing probability vibrating screen is a tradi…

What are Coal Gyratory Vibrating Sieves? First, we need to unders…

What is a Casting Sand Vibrating Sieve? Casting Sand Vibrating Si…

What is vibrating sieve for plastic pellets? Vibrating sieve for …

What is Graphite Vibrating Sieve? Graphite vibrating sieve, also …

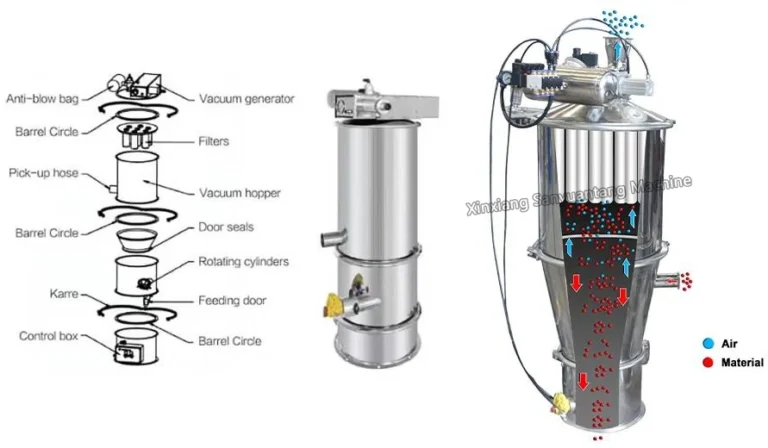

Vacuum feeding machine, also known as vacuum conveyor, negative p…

What is a vacuum feeder? In the pharmaceutical industry, material…

What is a vacuum conveyor? Vacuum Feeder Conveyor, also called va…

Standard test sieve, also called test sieving machine or called a…

Screw feeding machine is a mechanical automatic feeding equipment…

Double deck vibrating screen is one of the common and efficient s…

Grain belt conveyor is one of the main equipment used in agricult…

In industrial production, many granular materials need to be sepa…

Grain Bucket Elevator is a common vertical conveying equipment, w…

In modern industrial production, Vibro Sifter, as an important sc…

In the field of industrial screening, Gyratory Screen is an effic…

What is a wood chip screen? Sanyuantang Machinery will show you h…

Test sieve shaker (also known as standard test sieve/analysis sie…

The dewatering vibrating screen is a kind of automatic screening …

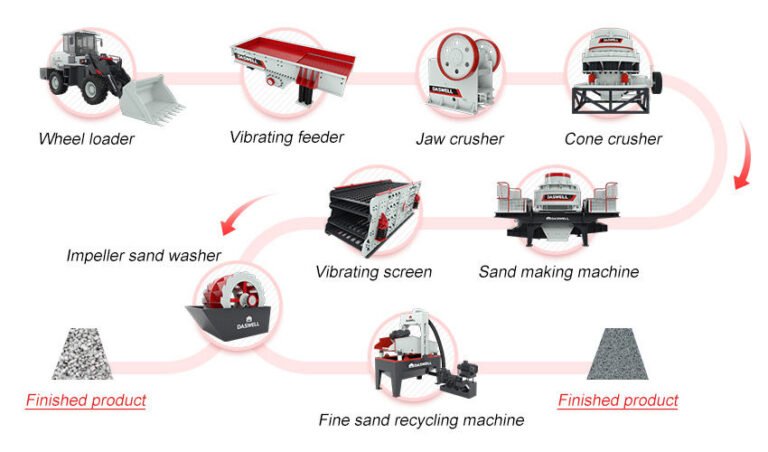

Sand production line is also called machine-made sand production …

Dewatering vibrating screen is the main equipment for industrial …

Learn the purpose of a dewatering vibrating screen, its working principle and applications in sand washing, mining, coal and tailings dewatering industries.

There are two major pain points in the sand making industry: high…

China has now become a global industrial machinery manufacturing …

Z type belt conveyor is a specially designed continuous conveying equipment, which combines the characteristics of traditional belt conveyors and elevators, and is suitable for occasions that require space turning or multi-layer conveying.

Z Type Belt Conveyor (also called “Z type elevator” or “bending belt conveyor”) is a belt conveyor used for feeding and climbing various materials.

As the main equipment for conveying a wide range of materials, th…

As a common conveying equipment, the belt conveyor has a prominen…

A bucket elevator is a mechanical device used to vertically transport bulk materials like grains, powders, and granules. It consists of buckets attached to a belt or chain, which lift materials from a lower to a higher level.

Bucket elevators are essential in industries such as agriculture,…

Bucket elevator is a highly efficient equipment for vertical tran…

Bucket elevator is a kind of mechanical equipment used for vertic…

Stainless steel bucket elevator is a kind of equipment made of st…

Vertical material conveying is a key aspect of industrial product…

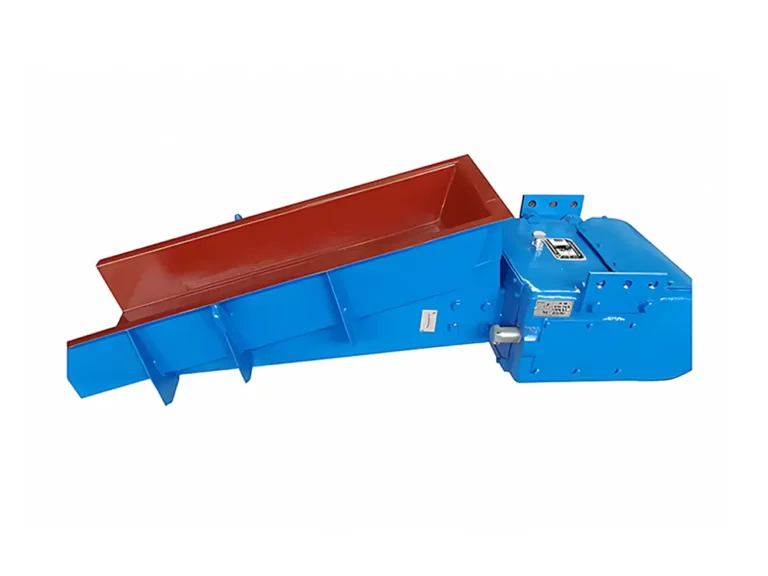

In industrial production, vibrating feeder is the key equipment f…

The electromagnetic vibrating feeder coil is a key component of t…

Electromagnetic vibrating feeder is a highly efficient material c…

V-Blender Pharmaceutical: Mixing Solutions for the Pharmaceutical…

Traditional high-temperature foundry sand cooling usually uses la…

Introduction V-type mixer is an industrial powder mixing equipmen…

V-blender machine is a commonly used equipment in powder processi…

Sand and gravel aggregates are important raw materials for the co…

To ensure a vibrating spiral elevators runs smoothly, regular ins…

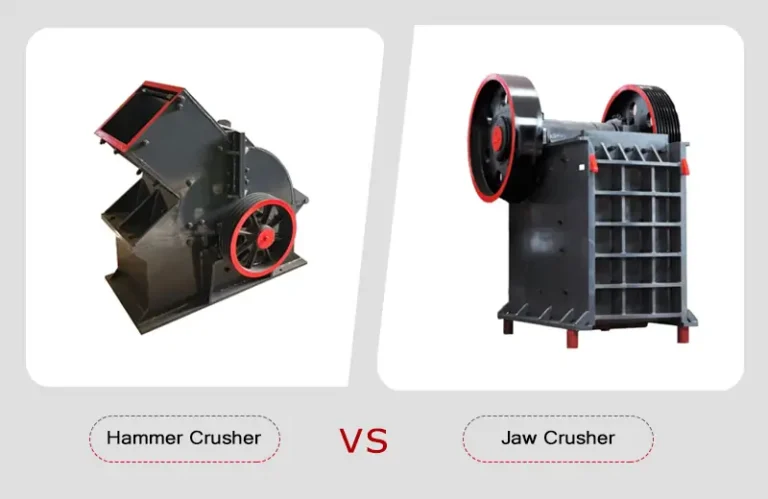

Jaw crushers are a type of crushing equipment widely used in indu…

In the mining, building materials, and metallurgical industries, …

What is the vibrating screen capacity The vibrating screen capaci…

When selecting vibrating screen models, consider the materialR…

When using an incline conveyor belt, the right fasteners can ensu…

内容结束

内容结束