Pharmaceutical screening equipment performs the same function as filter sieves or screening machines used in the pharmaceutical equipment industry. If you are involved in the food, chemical, or pharmaceutical industries, one of your key tasks is to separate particles of different sizes, a process known as screening. During this process, larger particles must be separated from smaller ones.

What tools or equipment should be used for this purpose? There are several tools, devices, and machines capable of performing particle separation. One of the most effective solutions is the pharmaceutical vibrating screening machine, which is widely used to screen and classify pharmaceutical powders, granules, and other materials according to particle size.

Pharmaceutical screening equipment plays a critical role in ensuring product purity, particle consistency, and production efficiency throughout pharmaceutical manufacturing.

Applications of Pharmaceutical Screening Equipment

1. Application in Pharmaceutical Powders

During the screening process of pharmaceutical powders, common problems include excessive fibers, high viscosity, static electricity, and low bulk density. These issues often lead to low screening throughput, poor continuous operation, difficult cleaning, and reduced production efficiency.

By adopting an ultrasonic anti-blinding system, pharmaceutical screening equipment effectively solves these problems by significantly reducing mesh blockage. For light materials with strong adsorption properties, this system improves screening efficiency and accuracy, greatly reduces labor intensity, and minimizes material waste.

2. Application in Pharmaceutical Granules

Generally, the particle size of traditional Chinese and Western medicine granules should be able to pass through 10–50 mesh screens. Fine particles that cannot pass through 10 mesh or 65 mesh screens should not exceed 8%. Pharmaceutical screening equipment ensures uniform granule size while preventing agglomeration and moisture-related clumping during the screening process.

3. Application in Pharmaceutical Extracts

- After coarse filtration from the storage tank, liquid extracts enter the pharmaceutical screening equipment for fine filtration. The finest filtration can reach 625 mesh (20 microns). The machine features an automatic slag discharge function, allowing continuous operation while eliminating screen blockage and improving recovery rates.

- During sedimentation, without screening equipment, effective liquid products are often lost together with residue. After screening, finished slurry can be effectively recovered, and the discharged waste residue becomes drier, reducing environmental pollution.

- Extracted traditional Chinese medicines generally contain high liquid content. Pharmaceutical screening equipment is used to recover more effective finished products, reduce waste, and lower overall production costs.

Features of Pharmaceutical Screening Equipment

- The machine is made of SS304 or SS316L polished stainless steel, ensuring clean and hygienic operation. The production process does not contaminate pharmaceutical products and complies with pharmaceutical hygiene standards.

- Suitable for screening materials ranging from 36 microns to 25 mm, with processing capacities from 100 to 5,000 kg per hour, depending on product characteristics, mesh size, and feed rate.

- All rubber components comply with pharmaceutical hygiene requirements and are made of pharmaceutical-grade silicone, meeting the production standards required by the pharmaceutical industry.

- Capable of continuous filtration and separation of up to five product grades in a single operation. Multiple machine sizes are available, suitable for both small-scale and large-scale operations, with diameters ranging from Ø400 mm to Ø2000 mm.

- The sealed system effectively eliminates airborne dust, protecting operator health and ensuring a safe production environment.

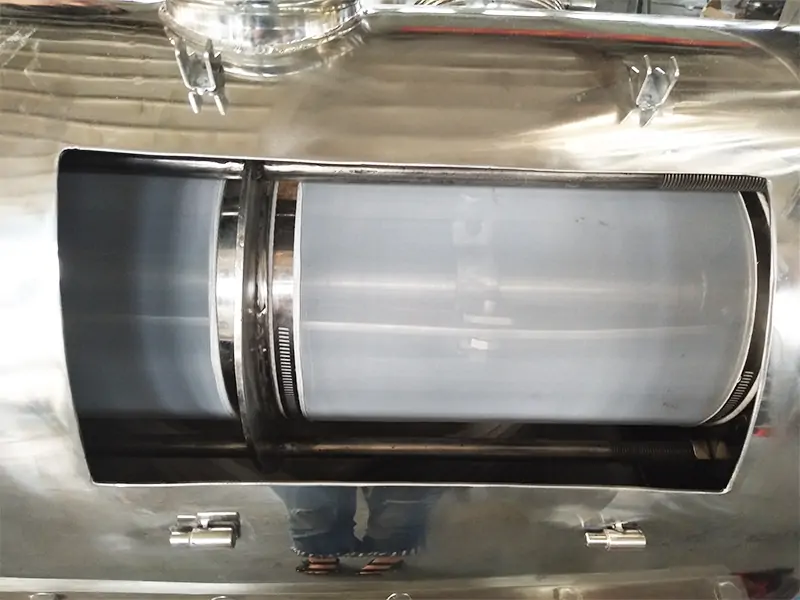

On-Site Use of Pharmaceutical Screening Equipment

Pharmaceutical screening equipment is an essential part of every pharmaceutical production process, especially in applications where product quality and integrity are critical. By removing oversized particles and contaminants, screening equipment ensures that raw materials and finished products meet quality requirements during production, storage, and before shipment or use.

Professional Manufacturer of Pharmaceutical Screening Equipment

Sanyuantang Machinery is one of the leading manufacturers located in China’s vibrating screen manufacturing hub, with over 30 years of production and manufacturing experience. We specialize in the design and manufacture of pharmaceutical screening equipment for pharmaceutical, food, and chemical industries.

If you encounter challenges in pharmaceutical screening applications, you are welcome to contact us at any time. Our professional technical team provides practical solutions and the latest screening technologies to help improve your production efficiency.

Email: info@sanyuantang.com

Phone: +86-18639095165