The rotary airflow sifter machine is an ultra-fine powder screening equipment. It uses the combined effect of airflow and centrifugal force to screen powder materials within 80-530 mesh, and the screening rate can reach 85-95%. It has the characteristics of large output, high efficiency, no sticking to the net, no blocking of mesh holes, fineness, etc. The output is 5-10 times or even higher than that of ordinary vibrating screens. The rotary sifter machine is suitable for screening and processing ultra-fine powders and special materials with light-specific gravity, high viscosity, high fiber content, static electricity, and easy agglomeration.

- Model: WQS18-85/WQS30-100/WQ70-180/WQ50-130

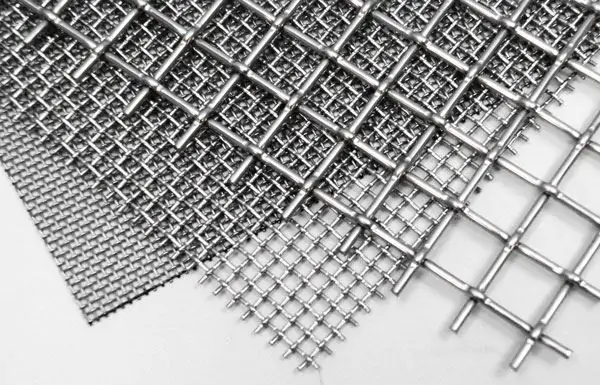

- Material: Stainless Steel 304

- Mesh Size: 5-500 mesh

- Voltage: 220V/380V/415V/450V

- Capacity: 100Kg-5tons/hour

- Customized: Acceptable

Price: $2250 – $5900 /Set

working principle

The working principle of the horizontal rotary airflow sifter machine is the screening process of the material under the combined action of airflow and centrifugal force. The specific working principle is as follows:

The body of the horizontal airflow screening machine is designed with specific airflow channels and centrifugal wind wheel blades. The screen is cylindrical. The material to be screened is sent into the screening machine through the screw conveyor system and enters the cylindrical screen. When the material passes through the wind wheel blades in the screen, it is subjected to the combined action of centrifugal force and cyclone propulsion, and the material is ejected through the screen, so that the fine material is discharged from the fine material outlet, while the material that cannot pass through the mesh slides along the screen cylinder wall and is discharged from the coarse material outlet.

Specifications

| Model | Materials | Power |

|---|---|---|

| WQS18-65 | Q235A | 2.2KW |

| SUW304 | ||

| WQS30-100 | Q235A | 4KW |

| SUW304 | ||

| WQS50-130 | Q235A | 5.5KW |

Details

Airflow Sifter Features

Application

The airflow rotary sifter is used in metallurgy, mining, pharmaceutical, food, chemical industry, metal powder, and nonmetal, among other industries.

The rotary airflow sifter is widely used in all kinds of fine powder which is difficult to screen, fine powder in the range of 50-500mesh can be very well screened. Such as light calcium powder, active calcium powder, active carbon powder, starch, medicine powder, fly ash, zinc powder, graphite powder, quartz sand powder, gold powder, pottery clay powder, hawthorn powder, fruit thinning powder, calcium hydroxide powder, pesticide powder, konjac powder, fluorescent powder, wood powder, flour, epoxy resin powder, manganese dioxide, sulfur powder, alumina powder, bakelite powder, magnesium oxide, perlite powder, iron powder, cotton linters, etc.

Metal Powder

Metal Powder Paint Coating

Paint Coating chemical powder

chemical powder Tapioca Flour

Tapioca Flour Milk Powder

Milk Powder Medicine Powder

Medicine Powder Sugar Powder

Sugar Powder Light calcium powder

Light calcium powder