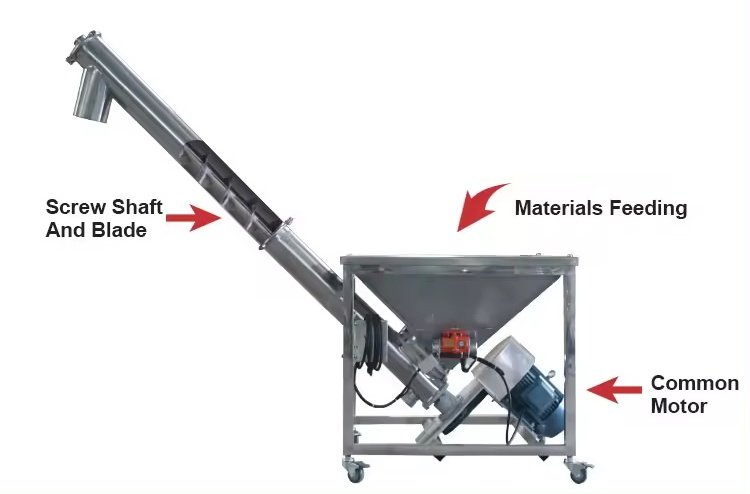

The screw feeder hopper is an automatic feeding machine suitable for various mechanical equipment. It can be customized according to the needs of the equipment that requires feeding operations, height, feeding speed, and other parameters.

The screw feeder conveyor with hopper is widely used in the transportation of powdery and granular materials in food, medicine, chemicals, plastics, feed, and other industries. It can be used with rotary vibrating screen, various crushers, mixers, and packaging machines to achieve matching material level tracking and automatic feeding, or it can be used alone on other occasions.

Materials: Stainless steel/ Carbon steel

Select angle: Tilt/Vertical

Hopper volume: 70-350 kg

Conveying capacity: 550-3300KG/hour

Conveying height: 2-70 meters (special requirements can be customized)

Feeding speed: 1 cubic meter/hour

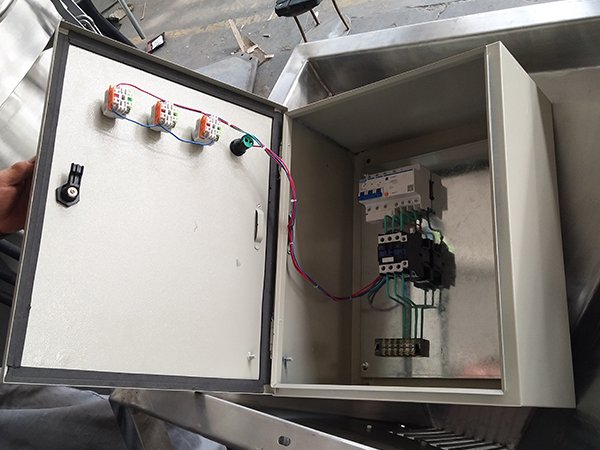

Power supply: 380V/220V

Power: 1.5KW/2.2KW/5.5KW

Weight: 80KG

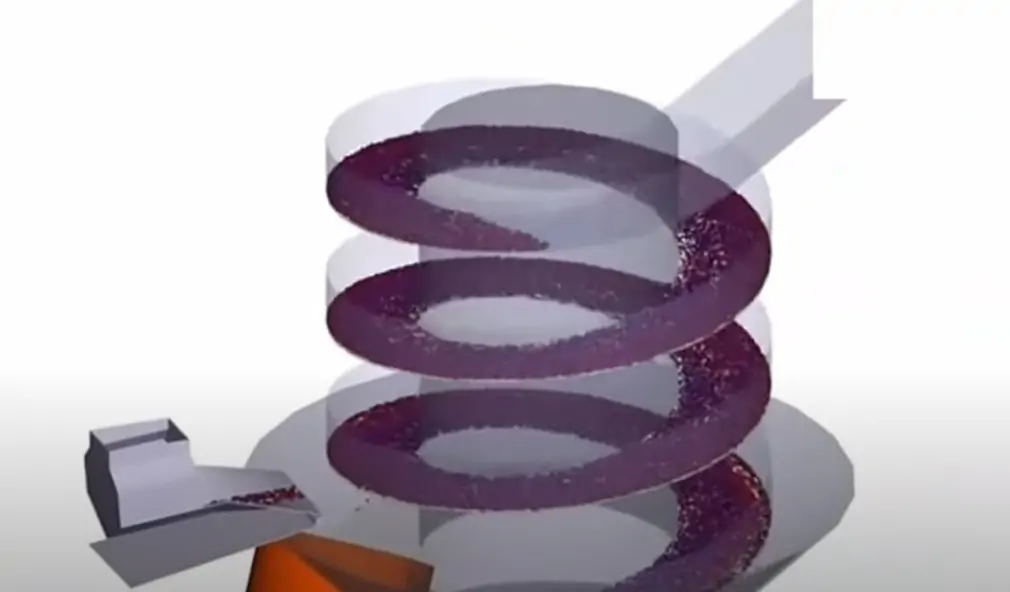

Working principle

The screw feeder hopper forms a closed conveying system in the pipeline through the combination of spiral body and spiral groove. When the motor drives the spiral body to rotate, the spiral groove also rotates. With the help of centrifugal force, materials are pushed and moved forward along the pipeline to achieve efficient material transportation. This design not only ensures the continuous flow of materials, but also effectively prevents leakage and pollution. It is suitable for a variety of industrial applications, such as chemical industry, metallurgy, food processing, etc.

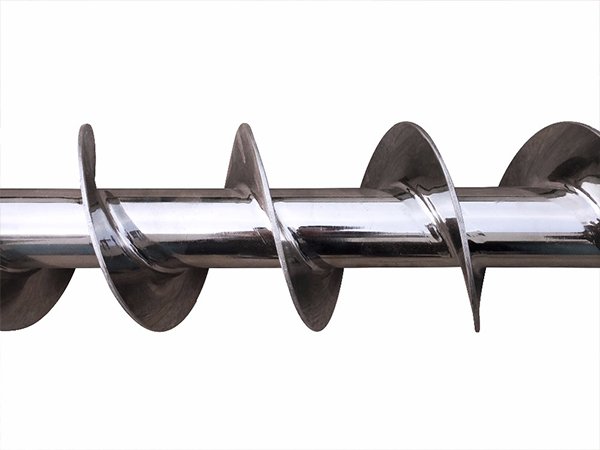

Spiral Shaft:

made of SUS 304 stainless steel, formed in one piece, and the blade angle and spacing can be customized according to needs. Horizontal Screw Feeder:

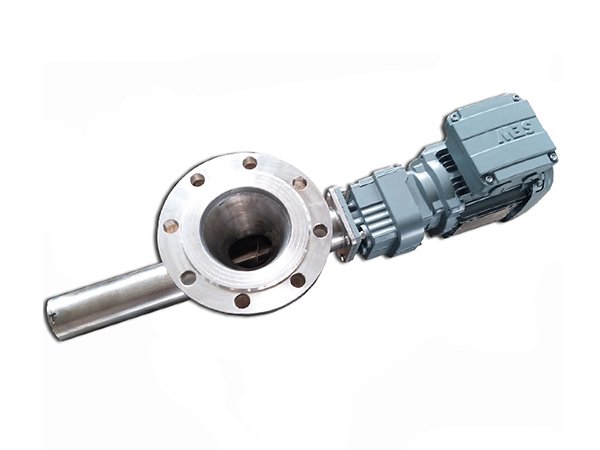

Horizontal Screw Feeder:

can make a horizontal screw feeder, that quickly connects with the machine. Hopper:

Hopper:

The size and shape of the hopper can be customized, usually round or square, and a screen can also be added to prevent debris from entering the hopper. Motor:

Motor:

pure copper motor, vibration motor switch control, adjustable amplitude, low noise. Frequency Converter:

Frequency Converter:

Can be equipped with frequency converter for speed regulation

Application

The screw feeder hopper is widely used in conveying a variety of materials, including but not limited to the following types:

- Powdered materials: flour, cement, gypsum powder, chemical powder, etc.

- Granular materials: grains, fertilizers, plastic particles, sand, etc.

- Small lump materials: coal, ore, feed, beans, etc.

These materials are widely in demand in agriculture, construction, chemical industry, metallurgy, and others. The efficient conveying capability of the screw conveyor hopper makes it an ideal choice for handling all types of materials. Whether horizontal or inclined conveying is required, screw feeders can provide reliable solutions to ensure the continuity and efficiency of the production process. Please read this article for details: How To Choose An Right Inclined Screw Conveyor Model?

Technical parameters of screw feeder hopper

| Model | Screw diameter(mm) | Screw pitch (mm) | Rotational speed of screw(r/min) | Convey measure(m3/h) | Motor power(kw) | Max dip angle(o ) |

|---|---|---|---|---|---|---|

| LS-100 | 100 | 100 | 140 | 2.2 | 2.2~18.5 | ≤20 |

| LS-125 | 125 | 125 | 125 | 4 | ||

| LS-160 | 160 | 160 | 112 | 8 | ||

| LS-200 | 200 | 200 | 100 | 11 | ||

| LS-250 | 250 | 250 | 90 | 22 | ||

| LS-315 | 315 | 315 | 80 | 34 | ||

| LS-400 | 400 | 355 | 71 | 64 | ||

| LS-500 | 500 | 400 | 63 | 95 | ||

| LS-630 | 630 | 450 | 50 | 150 | ||

| LS-800 | 800 | 500 | 40 | 210 |

Features of Screw Feeder Hopper

- Wide range of applications: suitable for decorative building materials, chemical industry, electric power, metallurgy, coal, food and other fields.

- Material compatibility: The screw conveyor hopper is suitable for horizontal or inclined conveying of powdery and granular materials. Generally, the material temperature should be below 200°C, and it is not suitable for transporting materials that are prone to mildew, agglomeration or high viscosity.

- Efficient design: The connection between the spiral shaft and the shaft adopts tongue-shaped fitting style, which is easy to install, disassemble and maintain, and has a low equipment failure rate.

- Long service life: It adopts a large and small head structure, and the hanging bearing does not come into contact with the material, so it has a long service life.

- Smooth transportation: It is not easy to get jammed or blocked during transportation. The headband seat bearing is located outside the shell, with good sealing performance and can be used for a long time.

- Compact structure: simple design, small size, and takes up less space.

- Flexible layout: multiple inlet and outlet designs, flexible layout.

- Two-way conveying: The conveying direction is irreversible and materials can be conveyed in two directions at the same time.

- Multifunctional operation: The operation is safe and reliable, and can realize various functions such as conveying, mixing, stirring, loosening, heating and heat dissipation.