Industrial sieve machine is a screening machine used to separate, classify, and filter materials in industrial production processes. It allows some particles to pass through the sieve holes through the relative movement between the bulk material and the screen surface, thereby separating materials such as sand, gravel, and crushed stone into different grades according to particle size.

Types of Industrial Sieve machine

In order to meet different sizes of screening needs, Sanyuantang manufactures several types of industrial sieving equipment available with throughputs ranging from 100kg to 15 tons/hour, depending on material characteristics, equipment type, mesh size, and machine feed flow rate.

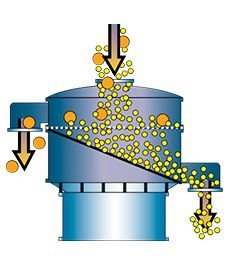

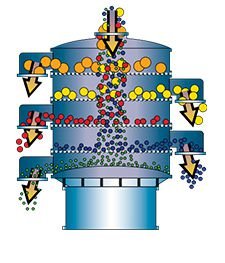

rotary vibrating sieve

The rotary vibrating sieve is small in size and can be customized with 1-5 layers. The output ranges from 100kg-3ton/hour. It is used for screening and grading solids, powders and liquids.

Application:

- Powder sieving: flour, sugar, salt, spices, powdered chemicals, pharmaceutical powders and powdered metals.

- Granule sieving: plastic granules, fertilizer granules, detergent granules and granulated sugar, sand, gravel, aggregates and various types of ores.

- Liquid sieving: pulp, juice, soy sauce, soy milk, wastewater, etc.

Ultrasonic vibrating sieve

Ultrasonic vibrating sieves are indeed highly effective in addressing various screening challenges encountered in industries. The ultrasonic vibrations help to mitigate issues such as strong adsorption, easy agglomeration, and high static electricity.

Application:

- Fine powders: pharmaceutical powders, fine chemicals, metal powders and powder additives.

- Fine particles: silica sand, alumina, calcium carbonate and talc.

- Sticky materials: powdered sugar, starch, cocoa powder and flour. Hygroscopic materials: pharmaceutical powders, food ingredients and chemicals.

- Electrostatic materials: plastic powders, polymer particles and toner powder.

- High-density materials: metal powders, ceramic powders and abrasives.

- Low-density materials: plastic beads, foam particles and lightweight aggregates.

Functions of Industrial Sieve Machine

Impurity Removal

Impurity Removal Particle Size Classification

Particle Size Classification Solid-Liquid Separation

Solid-Liquid Separation Enhanced Dewatering

Enhanced Dewatering

Impurity Removal: The industrial sieve machine is a key step in final quality assurance. It can effectively remove broken or undersized materials such as lumps and contaminants to ensure product quality.

Particle Size Classification: Precisely separate different sizes of particles from the material so that the final material is graded into different sizes. Large industrial sieves can grade up to 10 grades at the same time.

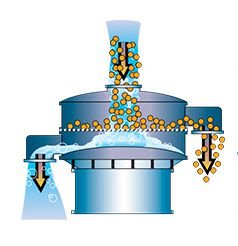

Solid-Liquid Separation: Industrial sieving machines can quickly separate insoluble solid materials from various slurries and even handle slag discharge easily. Most use single-layer sieves, but can also be configured with multiple layers for more complex separations.

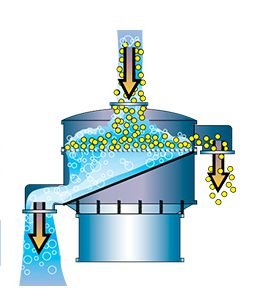

Enhanced Dewatering: For materials with high mud and water content, liquid sieving machine can be used to achieve efficient mud removal and dewatering. Up to 17-20 tons per hour can be processed.

Videos

Application

Food Products: Such as grains, rice, beans, nuts, seeds, coffee beans, and food additives.

Fibrous Materials: Such as wood chips, sawdust, pulp, and textile fibers.

Chemicals: Including various chemical powders, pellets, and crystalline materials.

Pharmaceuticals: Such as pharmaceutical powders, tablets, capsules, and medicinal herbs.

Liquid Slurries: Some rotary vibrating sieves are designed to handle liquid slurries by using special screens or configurations.

Recyclable Materials: Including plastic flakes, rubber crumbs, and other recyclable materials.

Other Materials: Depending on the specific design and configuration of the sieve, it can also handle other materials like ceramics, catalysts, animal feed, and more.

Grains

Grains Coffee Beans

Coffee Beans Flour

Flour

Medicine Powder

Medicine Powder Rubber Granules

Rubber Granules Paint Coating

Paint Coating Copper Powder

Copper Powder Quartz Sand

Quartz Sand Abrasives

Abrasives Kaolin

Kaolin Light Calcium Powder

Light Calcium Powder

industrial sieve machine manufacturer

Sanyuantang is a professional industrial sieve machine manufacturer, focusing on producing high-quality and high-efficiency screening equipment. We are committed to providing customers with customized screening solutions to meet the needs of different industries for screening equipment.

As a professional sieving machine manufacturer, Sanyuantang focuses on technology research and development and product innovation and continuously introduces advanced production processes and equipment to ensure the excellence and stability of product performance. Our vibrating sieving machine products are widely used in chemical, food, pharmaceutical, environmental protection, and other industries, providing customers with efficient and accurate screening services.

Sanyuantang has always adhered to the business philosophy of “quality first, customer first,” insisted on customer demand-oriented service, and provided customers with full-range service support. We have a professional technical team and after-sales service team that can respond to customer needs in a timely manner, provide technical support and solutions, and ensure that customers get the best experience during use.

In the future, Sanyuantang will continue to be committed to the research, development, and production of industrial sieving equipment, continuously improve product quality and service levels, provide customers with better screening equipment and services, and become a leader in the industry.