The pharmaceutical vibro sifter is a screening device specifically used in the pharmaceutical industry. It is mainly used to grade and screen materials such as pharmaceutical raw materials, preparations, and intermediates. The pharmaceutical vibro sifter uses the vibration generated by the vibration force to separate and classify the materials on the sieve to ensure the uniformity and quality of the drugs. In this blog, we will explore the sifting in pharmaceutical industry, covering its working principles, uses, types, and other relevant aspects.

Types of Sifters in the Pharmaceutical Industry

Pharmaceutical vibrating screens can be divided into many types according to their working principles and structural characteristics. The common types of pharmaceutical vibrating screens are as follows:

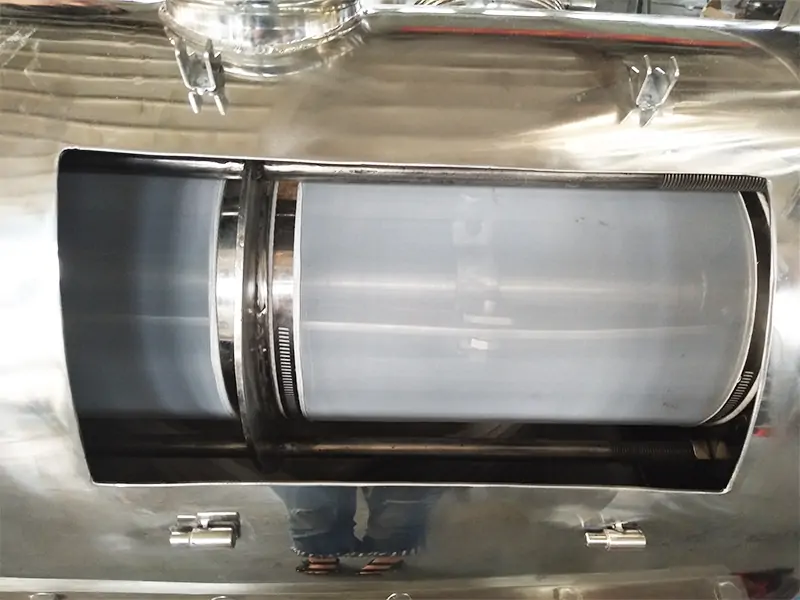

Rotary Vibrating Sifter

The working principle and characteristics of the rotary vibrating sifters are as follows:

- Motor drive: The motor transmits power to the screen frame through the shaft, causing the screen frame to vibrate periodically.

- Forced vibration: The vibration of the screen frame causes the material on the screen surface to be forced to vibrate, and the material forms a rotating forward motion trajectory on the screen surface.

- Screening effect: The material continuously rotates and moves forward on the screen surface, forming a small vortex, causing the material to repeatedly flip and disperse, thereby achieving accurate screening and screening. The screened fine material falls through the screen into the collection device below, while the coarse material is blocked above the screen and finally discharged from the edge of the screen surface.

The advantages of the rotary vibrating sifters are high screening efficiency and wide application range, especially for materials with high screening accuracy requirements.

Airflow Sifter

The airflow sifter (also called air-solid separation screen or airflow classifier) is a device that uses the combined action of airflow and screen to perform screening. Its working principle is mainly based on the following points:

- Airflow mixing: The material is first mixed with the airflow, and the material is suspended in the screen by the action of the airflow.

- Centrifugal force and cyclone propulsion force: Inside the screen, the rotation of the wind wheel blades causes the material to be simultaneously subjected to centrifugal force and cyclone propulsion force, which push the material toward the screen.

- Screening process: The material is ejected through the screen under the impetus of the airflow, and the fine material falls through the screen into the collection device below, while the coarse material slides along the screen wall and is discharged from the coarse material port.

The airflow sifter is particularly suitable for powdery materials that are easy to fly and have good fluidity, as well as occasions that require high-precision screening.

Linear Vibrating Screen

Linear vibrating screen (also called linear vibrating screen) achieves material screening through linear vibration. Its working principle is mainly based on the following points:

- Vibrator drive: Linear screen is usually driven by a vibrator (such as a vibrating motor) to generate linear vibration force.

- Material screening: When the material enters the feed port of the screening machine, the linear vibration force generated by the vibrator causes the material to move linearly on the screen. Larger particles are blocked by the screen and remain above the screen, while smaller particles fall through the screen into the outlet below.

- Continuous screening: The material is screened continuously on the screen until the desired screening effect is achieved. The screened fine and coarse materials are discharged through different outlets respectively.

Linear vibrating screen has the advantages of simple structure, stable operation, and high screening efficiency. It is particularly suitable for occasions with high screening efficiency requirements.

The main features of pharmaceutical vibro sifter

- High-precision screening: The pharmaceutical vibro sifter adopts high-precision screen, which can realize fine grading and screening of drug raw materials and preparations, ensure that the drug particles meet the predetermined size requirements, and ensure product quality and consistency.

- High-efficiency processing: The pharmaceutical vibrosifter has high screening efficiency and large processing capacity, which can meet the pharmaceutical industry’s requirements for production efficiency.

- Excellent hygienic performance: The pharmaceutical vibro sifter is usually made of corrosion-resistant and easy-to-clean materials such as stainless steel, which meets the high standards of the pharmaceutical industry for equipment hygienic performance.

- Compact structure: The structural design of the pharmaceutical vibro sifter is compact and reasonable, which is convenient for installation and use in the pharmaceutical workshop.

Pharmaceutical Vibro Sifter Uses

- The pharmaceutical vibro sifter has a wide range of applications in the pharmaceutical industry. Some of the key pharmaceutical vibro sifter uses include:

- Powder Grading: Ensuring that powders used in tablet and capsule production are of uniform size.

- Granule Screening: Separating granules by size to ensure consistent product quality during production.

- Contaminant Removal: Eliminating foreign particles or contaminants from raw materials before further processing.

- Mixing: Achieving uniform mixing of different components by breaking up agglomerates and ensuring even distribution.

- Wet/Dry Sifting: Suitable for both wet and dry materials, the pharmaceutical vibro sifter can handle a variety of products at different stages of production.

Factors Affecting Pharmaceutical Vibro Sifter Price

- The pharmaceutical vibro sifter price can vary based on several factors, including the machine’s specifications, brand, and additional features. Some of the key factors that influence the pharmaceutical vibro sifter price are:

- Material of Construction: Sifters made from high-quality stainless steel are more expensive but offer better durability and hygiene, which is essential in pharmaceutical applications.

- Screen Size and Number of Decks: The number of screens and their sizes can impact the price. A machine with multiple decks (layers of screens) allows for more precise separation but may be more costly.

- Motor Power and Efficiency: Machines with more powerful motors or advanced vibration technology may come at a higher price, but they offer improved efficiency and performance.

- Customization: Custom-built sifters tailored to specific manufacturing needs may be more expensive than standard models.

When considering the pharmaceutical vibro sifter price, it’s important to weigh the initial cost against the long-term benefits of investing in a high-quality machine that will provide reliable performance and durability.

Pharmaceutical Vibro Sifter Manufacturer

Sanyuantang is a leading pharmaceutical vibration screening equipment manufacturer and factory, focusing on the production of high-quality vibration screening machines, which are widely used in the pharmaceutical industry. The pharmaceutical vibration screens we produce are famous for their excellent quality and stable performance. The following are our strengths and service advantages:

- Technology leadership: Sanyuantang has strong design and development capabilities and can provide customized vibration screening solutions for the special needs of the pharmaceutical industry. Our products have reached the industry-leading level in screening accuracy, efficiency and processing capacity.

- Excellent quality: The company adheres to the quality concept of “quality first, customer first” and has passed CE, ISO9001 international quality management system certification to ensure that every piece of equipment shipped out of the factory has undergone strict quality inspections to meet the pharmaceutical industry’s high-quality requirements for equipment.

- Perfect service: Sanyuantang provides full-range support from pre-sales consultation, solution design, installation and commissioning to after-sales service. Our professional technical team can provide customers with timely and effective technical support and solutions to ensure the stable operation of the equipment during the pharmaceutical production process.

- Wide applicability: Sanyuantang’s vibration screening equipment is suitable for a variety of material screening needs in the pharmaceutical industry, including particles, powders, etc. The screening range is wide and can meet the requirements of different pharmaceutical processes for material particle size.

- High efficiency and energy saving: The company focuses on the energy efficiency ratio of the product. Through optimized design and the use of advanced manufacturing processes, the vibration screening equipment has low energy consumption and high efficiency during operation, which helps pharmaceutical companies reduce production costs and improve economic benefits.

Conclusion

The pharmaceutical vibro sifter is an essential piece of equipment in the pharmaceutical industry, whether you are sifting powders, granules, or other materials, the pharmaceutical vibro sifter produced by Sanyuantang produces the precision and efficiency needed to meet the highest standards of the industry.

For more information about pharmaceutical vibro sifter, please email us at info@sanyuantang.com