The pneumatic vacuum feeder machine is an automated feeding equipment that uses vacuum generation facilities to generate a vacuum to realize the conveying of powdered materials. It is mainly suitable for materials such as powdered materials, granular materials, powdered granular materials, and mixed materials. This equipment is often used in conjunction with vibrating sifters, tablet presses, capsule filling machines, mixers, packaging machines, and crushers, and is widely used in various industrial production lines.

The vacuum feeder can deliver up to 6T/H, with a maximum horizontal distance of 50m and a maximum vertical distance of 30m.

Working principle

- The vacuum pump generates a vacuum through the separation container of the vacuum conveying equipment. The material is sucked in from the feed port through the suction hose and the suction port.

- The air and material are separated in the filter bin of the separation container and the material is collected in the silo. The cyclone separator prevents fine powder from entering the filter to improve the filter’s efficiency.

- When the silo is full of material, the vacuum pump automatically shuts down and the pressure in the conveying equipment reaches equilibrium. The discharge valve opens, and the material flows out through the discharge port and falls directly into the storage container.

- During discharge, the filter chamber is automatically cleaned by the recoil airbag. Its special vibrator can assist in unloading to improve the efficiency of conveying viscous materials.

- The discharge chamber is closed and the entire conveying process starts again.

Structures

The pneumatic vacuum feeder machine is composed of a vacuum pump, filter, back-blowing device, vacuum tube, suction tube, hopper, discharge valve, feeder connection, bottom silo (with the level meter installed, optional), etc. The structures are connected by a quick-open clamp + sealing ring, which is airtight, leak-proof, and very easy to disassemble, with relatively low maintenance cost.

Special note: Since the vacuum feeding machine is a customized product, please consult our technical team for the specific product size, material, and model.

Specifications

| Model | Motor Power(kw) | Capacity(kg/h) |

|---|---|---|

| ZKS-1 | 1.5 | 80-200kg |

| ZKS-2 | 2.2 | 200-300kg |

| ZKS-3 | 3 | 300-600kg |

| ZKS-4 | 5.5 | 500-1000kg |

| ZKS-6 | 5.5 | 1000-2000kg |

| ZKS-7 | 7.5 | 2000-3000kg |

| ZKS-10-6 | 7.5 | 4000(Conveying distance10m) |

| ZKS-20-5 | 11 | 4000(Conveying distance20m) |

vacuum feed systems

Pneumatic Vacuum Feeder Machine

Pneumatic Vacuum Feeder Machine Electric Vacuum Feeder Machine

Electric Vacuum Feeder Machine Electric Vacuum Feeder Machine

Electric Vacuum Feeder Machine

Features

- Closed conveying, no dust leakage, no cross-contamination, energy saving, and environmental protection.

- Simple operation, intelligent control, high automation, low operation and maintenance costs.

- Modular design, small size, easy to install and disassemble for cleaning

- SS304 or SS316L material, polished inner wall to prevent material adhesion, in line with GMP standards.

- Wear-resistant titanium filter, anti-clogging, long service life, eliminate static electricity.

Application

Medicine: raw materials, powders, granular materials, mixed materials (no stratification during the transportation process), tablets, capsules, etc.

Food: additives, raw materials, candy, flour, cocoa powder, monosodium glutamate, crystals, etc.

Chemicals: carbon powder, metal powder, dyes, pigments, etc.

Agriculture: transportation of bulk materials such as crop granular seeds, urea fertilizers, etc.

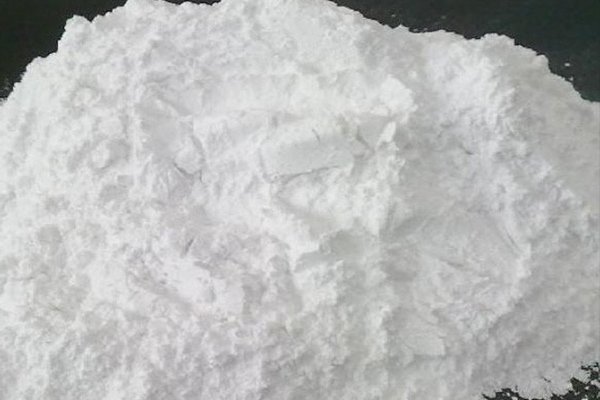

Starch Powder

Starch Powder Medicine Powder

Medicine Powder Paint Coating

Paint Coating Tungsten Powder

Tungsten Powder Abrasives

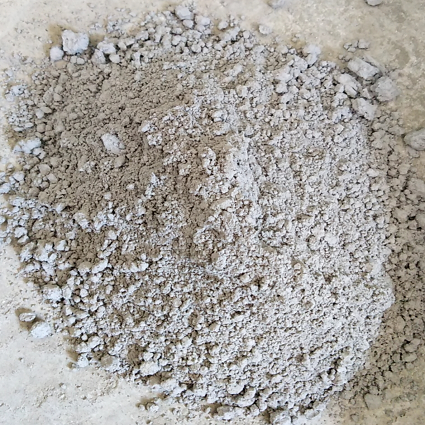

Abrasives Fly Ash

Fly Ash