The industrial flour sifter machine is an Inline sifter machine, mainly used to filter and remove impurities from flour in food factories, including bran, particles, insect eggs, and stones, to loose the sieved flour for fluffy pastries, ensuring the wheat flour remains light and free from caking.

It uses one or two vibration motors as the excitation source, and the powder is directly discharged under the screen. This kind of circular vibrating screen has high working efficiency and high screening accuracy and is suitable for large-scale production needs.

- Model: SYM-1500/1200/1000/800/600mm

- Material: Stainless Steel 304/316

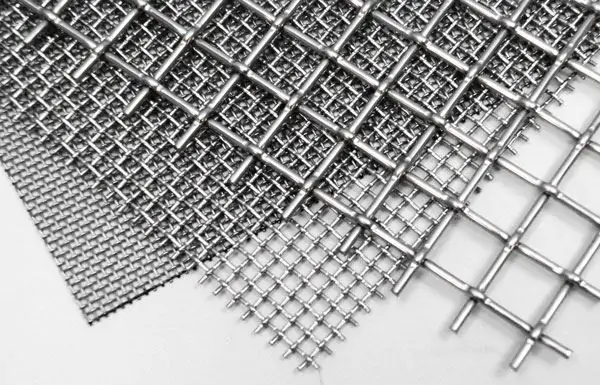

- Mesh Size: 2-100 mesh

- Layers: 1-2 layers

- Motor: single or double motor

- Capacity: 1-3 tons/hour

- Customized: Acceptable

Price: $750.00 – $1,899.00/Set

Features

- The structure is simple and compact, small in size, does not take up space, and is easy to move.

- All stainless steel design, beautiful appearance, and durability.

- Low working noise, ultra-low silent design; low energy consumption, and high efficiency.

- Automated operation, capable of 24-hour continuous production;

- Fully enclosed structure to prevent flying dust and is environmentally friendly.

- The large-flow discharge port is at the bottom, which facilitates the installation of equipment for assembly line operations.

- The upper discharge port can be adjusted arbitrarily within 360°, which is convenient for installation and use.

- New mesh frame structure, the mesh has high tension and long service life, and customers can quickly replace the screen themselves.

Working Principle

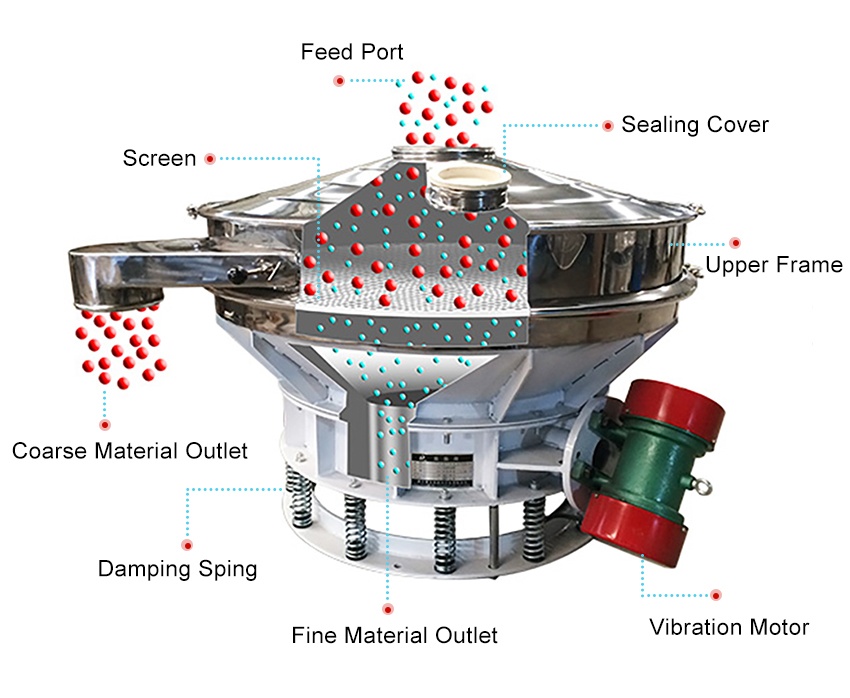

The working principle of the vibrating flour sifter is to vibrate the screen frame through the excitation force generated by the vibration motor, thereby screening the raw material particles on the screen.

The specific process is: after the raw materials are evenly distributed in the screen frame, they are affected by the vibration force. The large particles move to the front edge under the action of the vibration force and are gradually discharged from the equipment outlet, while the small particles pass through the screen and are discharged from below.

The material outlet is discharged, thus realizing the separation of materials with different particle sizes.

Structures

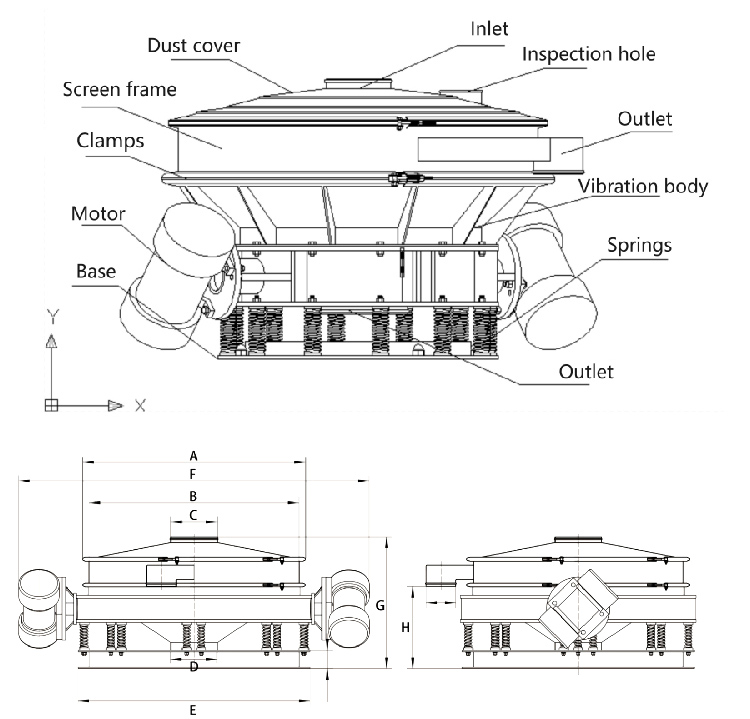

The flour sifting machine consists of a vibration plate, a vibration motor, a shock-absorbing spring, a screen frame, a sealing cover, rubber products, and a bottom frame.

The inlet and outlet are designed in the same vertical direction, and the large flow outlet at the bottom allows materials to be discharged directly.

The discharge speed is fast, and the output is 2-5 times that of ordinary round screens. The detailed structure is shown in the figure below.

To meet food safety and hygiene standards during the flour production process, industrial flour sifters are generally made of all stainless steel to avoid contamination of the parts in contact with the flour. The seals of flour sieves are usually made of special silicone materials for the food industry to ensure compliance with the hygienic requirements of the food industry.

Details

Screen Support

Screen Support Feeding Port

Feeding Port Motor

Motor Valve

Valve

Specifications

| Model | SYM600 | SYM800 | SYM1000 | SYM1200 | SYM1500 |

|---|---|---|---|---|---|

| Single motor power | 0.18 | 0.18 | 0.25 | 0.55 | 0.55 |

| Dual motor power | 0.12*2 | 0.18*2 | 0.18*2 | 0.25*2 | 0.55*2 |

| Screen diameter | 550mm | 750mm | 970mm | 1170mm | 1470mm |

Single Motor

Suitable for screening small particle materials, small output, and low price.

Dual Motor

It is suitable for screening powdery materials, with large output and finer quality.

Custom according to Your Needs

The industrial flour sifting machine is mainly used to remove impurities, so usually makes one layer of screen. Common mesh sizes for industrial flour sifters: 12 mesh, 20 mesh, 24 mesh, 30 mesh, 40 mesh, 60 mesh, etc. It can be designed and manufactured according to user requirements, such as heightening the feed port and installing a butterfly valve at the discharge port.

Open type

Open type Add 2 observation ports

Add 2 observation ports Add discharge port

Add discharge port

Raised edges

Raised edges

Application

The industrial flour sifting machine is a coarse screening equipment among fine screening equipment. It can filter powders and granules within 200 meshes. They have a large processing capacity and are easy to integrate into production lines. It is widely used in washing powder, chemical fertilizers, medicinal powders, salt, monosodium glutamate, seasonings, milk powder, starch, flour, rice noodles, carbon powder, graphite powder, etc.

Industrial Flour Sifter Machine Solutions

| Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr t/hr) |

|---|---|---|---|---|---|

| Flour | 0.6 | 24 | SYM-1000-1S | Dry | 1500㎏ |

| Rice Flour | 0.5 | 100 | SYM-1000-1S | 300kg | |

| Corn Starch | 0.6 | 40 | SYM-1000-1S | 1600kg | |

| Degreased toner | 0.57-0.7 | 24 | SYM-1000-1S | 3000kg | |

| Milk powder | 0.51-0.8 | 12 | SYM-1200-1S | 1600kg |

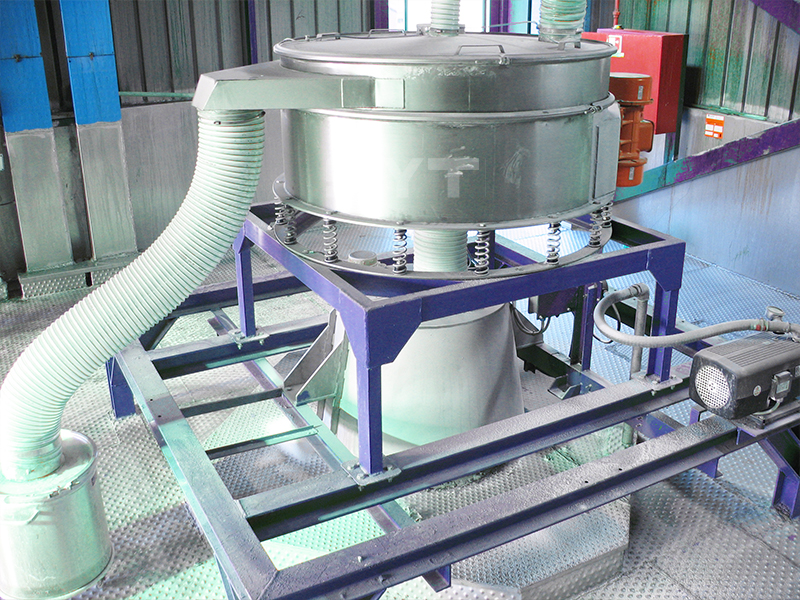

Customer Site

Difference Between Single Motor and Dual Motor

Due to the difference in the number of motors, in-line screens are divided into single-vibration source flour sifter machine and dual-vibration source flour sifter machine.

The single vibration source vibrating flour sifter has only one vibration motor, which only performs elliptical motion on the screen. The excitation source is relatively single, and the materials passing through the screen are limited. It is suitable for screening materials with small output requirements.

The bottom of the dual-vibration source industrial sifter machine has a straight-discharge design, and the screened materials are discharged more smoothly. In the application of coarse screening of materials, it has a higher throughput than a rotary vibrating screen of the same diameter. The dual-motor direct-discharge screen The running trajectory can be adjusted in a variety of ways. Compared with the same period, the single vibration source straight screen can screen a wider range of materials and has a larger processing capacity.