Circular vibrating screen machine is fit for dry and wet sieving, classification of powdery, granular, and filamentary materials, and dehydration of materials. If fine sieving is required it can be satisfied by adopting a high-efficiency screen mesh-cleaning device to improve the sieving. For wet sieving, it is especially fit for the separation of sludge (wastewater) and preliminary compression of mixed matter of solid and liquid materials.

Different Types of Circular Vibrating Screen

We have different types of products to suit unique needs, and when selecting configurations and models, we will provide detailed guidance and suggestions based on your application needs.

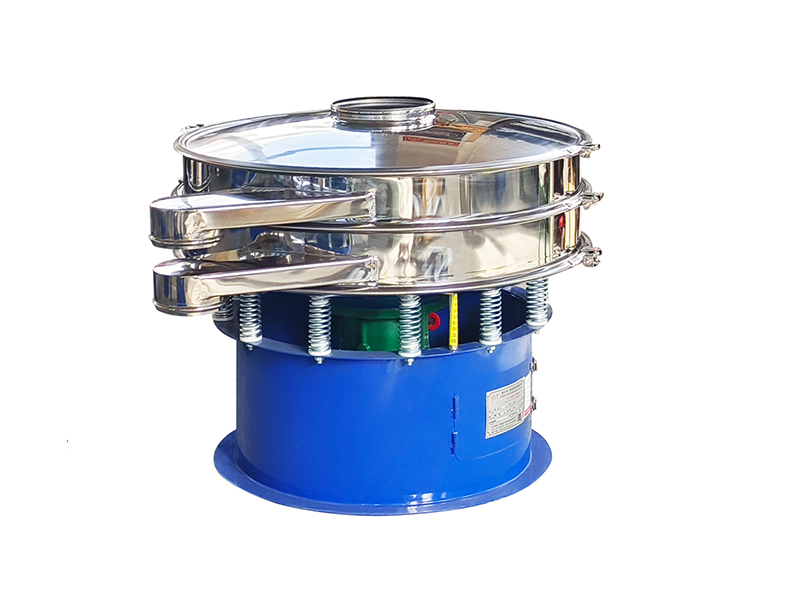

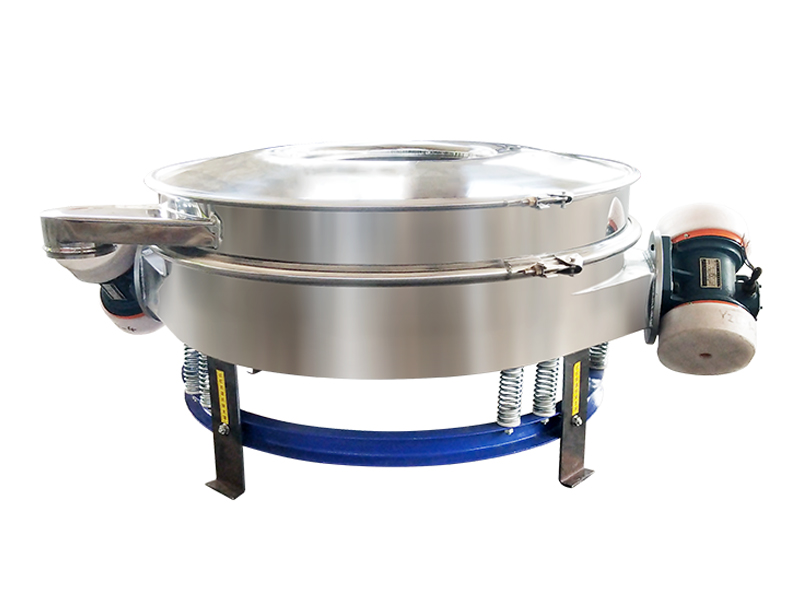

Rotary Vibrating Screen

Sieving and separating materials with finer particle sizes, down to 20 microns, with minimal blocking.

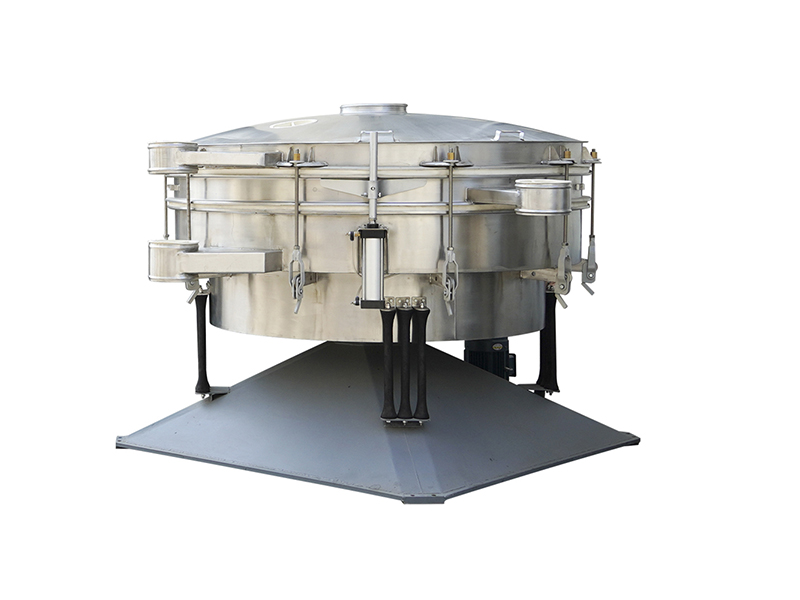

Tumbler Screener

It is suitable for screening and grading various dry powdery and granular products, with large output and high efficiency.

Inline Vibratory Screener

Add context to your column. Help visitors understand the value they can get from your products and services.

Application

- Chemical industry

- Resin, coating, industrial drug, cosmetics, paint, and so on

- Food industry

- Sugar powder, starch, salt, rice flour, milk powder,soya-bean milk, egg powder, soy sauce, fruit juice, palm oil.

- Metal metallurgy mining

- Aluminum powder, lead powder, copper powder, ore, alloyed powder, kaolin, lime, quartz sand, etc.

- Pollution treatment

- Waste oil, waste water, dyeing wastewater, auxiliaries, activated carbon, etc.

Wheat Flour

Wheat Flour Milk Powder

Milk Powder Oil Fracturing Proppant

Oil Fracturing Proppant Grain Pellets

Grain Pellets Medicine Powder

Medicine Powder PP/PE Granules

PP/PE Granules Paint Coating

Paint Coating Metal Powder

Metal Powder Emery

Emery

Videos

Features

Small size, lightweight, and easy to move. The direction of the discharge port can be adjusted at will, and thick and fine materials are automatically discharged and can be operated automatically or manually.

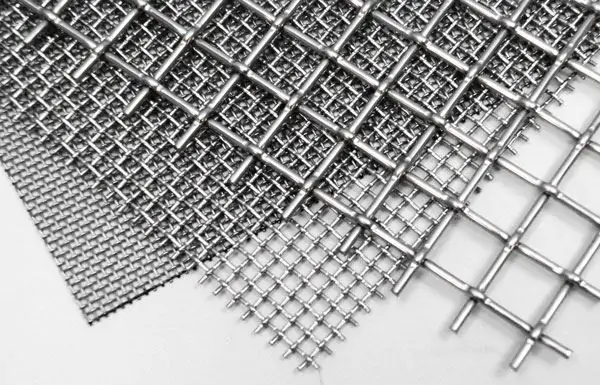

The screening precision is high, the screening is as fine as 600 mesh or 0.02mm, and the filtration is as small as 5 microns. Any powder, granule, or slime can be used.

Classified screening

Classified screening, which can screen one to five layers of mesh, and can perform two to six levels of sorting or filtration at the same time.

screen not easily clogged

The screen is not easily clogged and the powder does not fly. Equipped with a screen cleaning device, it can reduce the blocking of materials during the screening process.

Easy to change the screen

Special grid design (mother-and-child type). The screen lasts a long time. Easy to change the screen. It only takes 3-5 minutes. Easy to operate and easy to clean.

high power Motor

It adopts a flange motor, which has high power, high screening efficiency, and low noise, there is no mechanical action. Easy to maintain.

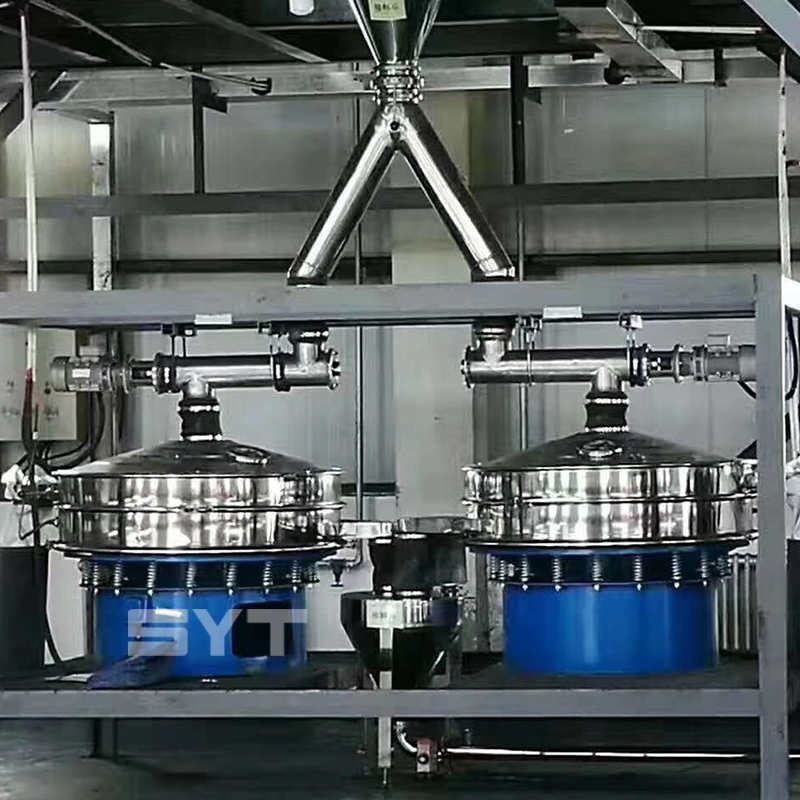

Customer Site

Why Choose US?

China Circular Vibrating Screen Manufacturer & Supplier

Sanyuantang Machine is a manufacturer of direct sale circular vibrating screens, is committed to providing factory price and high-quality products. We offer various types of rotary vibrating screen and can customize the design and production according to customers’ needs. Our aim to provide effective screening and separating solutions, and we can help customers solve practical problems in time, whether it is selection consultation or troubleshooting.

We will provide you with the following services:

- 1. Material and parts warehouse management services, which can help customers manage their inventory.

- 2. Spare parts supply program management services to ensure that our customers can obtain the parts they need promptly.

- 3. We also provide machine repair and packaging services for full support.

- 4. Our goal is to provide you with products with excellent performance and reasonable prices. If you have any further questions or need more information, we’d be more than happy to help. Please feel free to contact us, we will reply as soon as possible and give you the most professional guidance.