Selecting the appropriate rotary vibrating screen models hinges on several factors that vary according to the user’s specific needs and applications. To make the right decision, consider the following steps:

Table of Contents

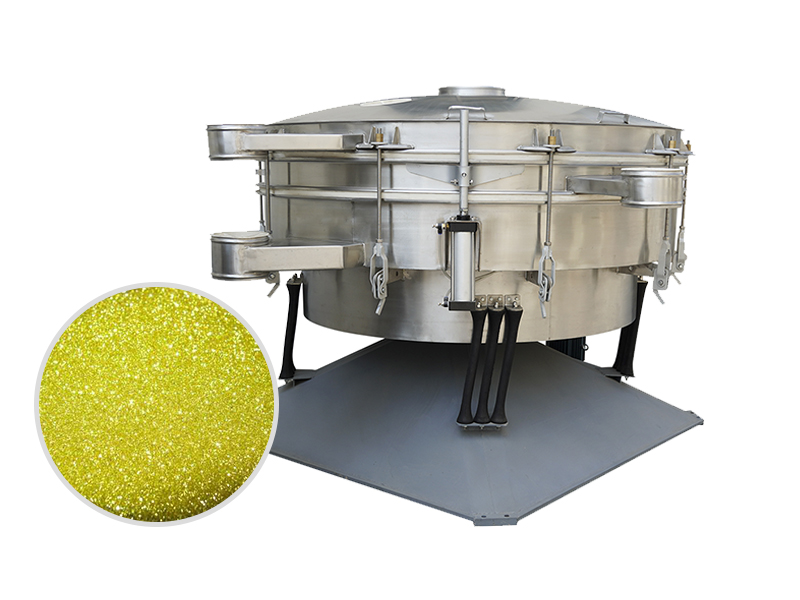

Rotary Vibrating Screen Models

| Model | Diameter (mm) | Feed Size (mm) | Frequency (rpm) | Number of Layers | Power (kW) | Capacity (kg/h) |

|---|---|---|---|---|---|---|

| SY-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| SY-600 | 600 | <10 | <1500 | 1-5 | 0.25 | 200 |

| SY-800 | 800 | <10 | <1500 | 1-5 | 0.55 | 500 |

| SY-1000 | 1000 | <10 | <1500 | 1-5 | 0.75 | 800 |

| SY-1200 | 1200 | <10 | <1500 | 1-5 | 1.1 | 1200 |

| SY-1500 | 1500 | <10 | <1500 | 1-5 | 1.5 | 1800 |

| SY-1800 | 1800 | <10 | <1500 | 1-5 | 2.2 | 2000 |

Screening Output – Model Selection

The rotary vibrating screens are categorized into three sizes: large (SY-1500, SY-1800), medium (SY-800, SY-1000, SY-1200), and small (SY-400, SY-600). Choose a screen size that aligns with your output requirements. Smaller models suit household use or low-output needs, while larger models like the 1200, 1500, and 1800 series are recommended for higher output demands. Available site space should also be considered when selecting a vibrating screen model.

Screening Material Properties – Screen Mesh

The mesh of the rotary vibrating screen can vary from fine (up to 500 mesh or 0.028mm) to accommodate different materials and purposes of use, such as grading or impurity removal. Before choosing a vibrating screen type and mesh size, determine the material properties (liquid, powder, granular) and intended use. For liquids and fine powders, opt for a high-mesh, dense screen, for granular materials, a larger mesh may be more suitable.

For classification purposes, consider multi-layer screens (up to 5 layers, 6 levels) to meet specific grading requirements. Conversely, single-layer screens are sufficient for simple impurity removal tasks.

Rotary Vibrating Screen Material Type – Screen Material

Carbon Steel

Carbon Steel Full Stainless Steel

Full Stainless Steel Anti Corrosion Plastic PP

Anti Corrosion Plastic PP

The rotary vibrating screens are available in two primary materials: carbon steel and 304 stainless steel. Choose the material based on your specific needs. Carbon steel screens are suitable for screening chemical, metal, or plastic materials, whereas 304 stainless steel is recommended for applications requiring high hygiene standards, such as pharmaceuticals, salt, or sugar.

By following these steps and considering your unique requirements, you can confidently select the right vibrating screen model for your application.