What is vibrating sieve for plastic pellets?

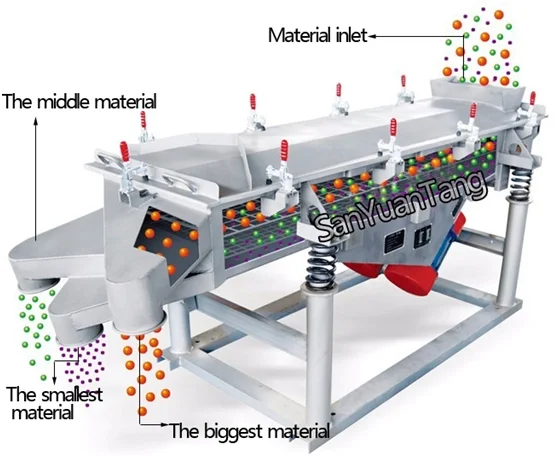

Vibrating sieve for plastic pellets is a vibrating machine used to screen, classify and remove plastic pellets. It is also an important piece of equipment in the production of plastics and is commonly found in Linear Vibrating Scree, Rotary Vibrating Screen and Ultrasonic Vibrating Screen. it is commonly used in the production of plastics where the process is located after pelletising, cooling or drying, and prior to packaging or moulding, and where the vibration is used to By vibrating the screen, plastic particles of different sizes are separated and impurities are removed, so that the fineness and purity of the finished product can be controlled.

Common Problems and Solutions in Plastic Pellet Production

In the production of plastic granules, the screening process often encounters problems such as screen clogging, particle damage, impurity residue, inaccurate grading and low efficiency. To solve these problems, the following solutions can be adopted:

- Screen clogging: Because fine particles or static particles are easy to clog the mesh, so we can use ultrasonic vibrating screen or rotary vibrating screen with a bouncing ball/ultrasonic screen cleaning device, using high-frequency micro-amplitude vibration or auxiliary screen cleaning.

- High particle breakage rate: adjust the vibrating screen excitation force size and vibration mode, such as choosing softer rotary vibrating screen instead of strong vibration linear vibrating scree, or choosing rubber screen mesh to buffer the impact of particles to reduce the breakage of brittle plastic particles such as PS, some engineering plastics.

- Impurity removal is not clean: choose a multi-layer screen combination, so that the target particles pass through smoothly and impurities such as head, oversized particles, foreign matter removal; strengthen the pretreatment of raw materials or vibrating screen before the addition of magnetic device adsorption of metal shavings.

- Insufficient grading accuracy: optimise the screen aperture configuration and vibration parameters (amplitude, frequency), so that different particle size particles are effectively separated, such as distinguishing between reuse material and new material particles; regularly check the screen wear and replace it in time.

- The output is not up to the standard or low efficiency: according to the characteristics of particles and processing capacity requirements, choose the appropriate type such as linear vibrating scree for large output of primary screening, rotary vibrating screen for fine grading.

Comparative analysis of vibrating sieve for plastic pellets solutions

| Feature/Requirement | Linear Vibrating Screen | Rotary Vibrating Screen | Ultrasonic Vibrating Screen |

|---|---|---|---|

| Screening Principle | Linear jumping motion on screen | 3D rotary motion on screen | High-frequency ultrasonic + mechanical vibration |

| Primary Advantage | High capacity, coarse screening & dewatering | High precision, wide particle size range | Exceptional anti-blinding, ideal for super-fines & high-static materials |

| Screening Precision | Medium (general grading) | High (fine grading) | Ultra-high (super-fine grading) |

| Applicable Pellet Size | Coarse pellets (>3mm) | Wide range (0.074mm – 10mm) | Super-fines/micro-powders (<0.5mm) |

| Processing Capacity | High | Medium | Medium (relative to precision) |

| Anti-Blinding Effectiveness | Standard | Good (with cleaning balls) | Excellent (especially for fines/static materials) |

| Particle Breakage Risk | Medium (controlled excitation) | Low | Minimal |

| Typical Plastic Applications | • Primary screening of virgin/recycled pellets • Post-cooling dewatering | • Precision grading post-pelletizing • Impurity removal • Recycled material sorting | • Engineering plastic powders • Easy-agglomeration additives • High-purity raw materials • High-static materials (e.g. PP/PE powders) |

| Cost Consideration | Generally lower | Medium | Higher |

Common applications of vibrating sieve for plastic pellets

Vibrating sieve for plastic pellets is the key equipment to ensure the quality in plastic pellet production, the following are the common application scenarios and advantages:

Fresh material production:

- Linear Vibrating Scree: for initial grading and cooling and dewatering of high volume pellets after extrusion pelletising.

- Rotary Vibrating Screen: Post-pelletising fine grading such as separating passes from oversize/small particles, removing unmelted particles and impurities.

- Ultrasonic Vibrating Screen: Screening of high value engineering plastics such as PEEK, PPS fines or micro-powders, removal of very fine impurities, handling of static prone raw materials such as PP fines.

Recycled Material Processing:

- Linear Vibrating Scree: Primary screening and dewatering of bulk materials after crushing and cleaning.

- Rotary Vibrating Screen: Core equipment for removing impurities and separating different quality grades by particle size.

- Ultrasonic Vibrating Screen: Processing of high purity recycled materials such as PET bottle flakes after fine crushing to remove micron-sized impurities.

Modifiers and masterbatches:

- Rotary Vibrating Screen: uniformity screening of mixed particles to remove agglomerates or undispersed pigment particles.

- Ultrasonic Vibrating Screen: Screening of fine powders of carrier resins and micronised powders of functional additives such as flame retardants and antioxidants to ensure high dispersibility.

Pre-packaging and moulding:

Rotary Vibrating Screen: Final screening before packaging or injection/extrusion to achieve particle purity and consistency of particle size and to prevent clogging of downstream equipment such as injection moulding machine screws.

Conclusion:

Through the above article content we know that vibrating sieve for plastic pellets solution in plastic pellet industry. We are a manufacturer in vibrating sieve industry with 30 years of vibrating sieve manufacturing capacity and professional solution for all kinds of vibrating sieving solutions. If you now have any vibrating sieve problems now you can contact us, we have a professional solution team for you to answer all kinds of vibrating sieve problems and how to buy and so on.