PFL Vertical compound crusher, also known as compound sand making machine, is a highly efficient fine crushing and coarse grinding equipment, widely used in ore crushing, cement production, artificial sand making, and other fields. This equipment combines the advantages of traditional crushers, has a high crushing ratio, low energy consumption, and good processing capacity, and is especially suitable for crushing medium hardness and below ores, such as river pebbles, granite, basalt, etc.

- Model: PFL

- Feed size: 100~240mm

- Discharging particle size: <3 (mm) , 70-90%

- Production capacity: 8-120t/h/hour

- Application: Cement raw materials, clinker, ore dressing and crushing, construction sand, lead-zinc ore, iron ore, sandstone, gypsum, coal gangue, lump coal, limestone, dolomite, granite, basalt, etc.

Price: US $6,300.00 -$ 150,00.00 / Set

Vertical Compound Crusher Working Principle

The working principle of the vertical shaft compound crusher is to accelerate the material through the high-speed rotating rotor. After the material hits the plate hammer on the rotor, it is thrown at high speed to the liner or other counterattack device in the crushing chamber, and is impacted and squeezed again, thereby achieving material crushing. Since the crushing process adopts multiple action modes such as impact, extrusion and grinding, the crushing effect is more uniform and the particle size is finer. The unique design of the equipment enables the material to be fully crushed in a shorter time, and can effectively reduce the phenomenon of over-crushing, so that the particle size and shape of the final product are stable.

Structure

The main components of Vertical Shaft Compound Crusher include frame, rotor, hammer head, liner, feed port, discharge port, etc. It has the characteristics of large crushing ratio, low energy consumption, stable operation, simple structure, and convenient operation and maintenance.

The equipment provides two structural forms: upper transmission and lower transmission, and is highly efficient and energy-saving. When used in conjunction with a mill, it can increase the mill’s output by about 40% and reduce system power consumption by about 30%.

Details

Technical Parameter

| Model | Feed opening | Input size(mm) | Finished product size | r/min(t/h) | Power(kw) | Capacity(t/h) | Number of linings | Number of hammer heads | Overai dimensions | Weight(t) |

|---|---|---|---|---|---|---|---|---|---|---|

| 700-5700-6700-8 | 890/570/450 | >50 | 4-804-1004-120 | 1400 | 11-1518.522 | 3-5 | 242832 | 151824 | 1410/740/16301410/730/17401410/730/1900 | 11.21.5 |

| 800-4800-6800-7 | 985/670/420 | >60 | 4-804-1204-150 | 1100 | 22-3037-4545 | 8-15 | 244048 | 121821 | 18500/830/17601500/830/19801800/830/2420 1800/1020/2410 | 1.51.82.3 |

| 1000-41000-51000-6 | 1280/700/580 | >70 | 4-804-1004-120 | 1100 | 455555 | 15-30 | 406070 | 122518 | 1800/1120/19401800/1120/20701800/1120/2230 | 2.533.5 |

| 1250-41250-51250-6 | 1600/900/725 | >70 | 4-804-1004-120 | 960 | 757590-110 | 30-50 | 4848140 | 162018 | 2500/1400/24102500/1400/24102500/1380/2370 | 4.756 |

| 1500-41500-51500-6 | >70 | 4-804-1004-120 | 860 | 110132160 | 40-70 | 98 140 | 162024 | 3000/1670/24303000/1670/27803000/1700/3270 | 7.58.511 | |

| 1750-41750-6 | >80 | 4-804-120 | 650 | 185220 | 80-120 | 112160 | 1624 | 3410/2000/30903410/2000/3440 | 1214.5 | |

| 2000-4 | >100 | 4-100 | 560 | 315 | 100-150 | 16 | 20 |

* Note: 1. The production capacity of this equipment is a reference value. The production capacity is affected by factors such as compressive strength, breakability, corrosiveness, capacity, gradation, moisture content, crystal structure, and processing technology of the raw materials.

Features

High wear resistance, easy to adjust

Wear-resistant and consumable parts, adjustable crushing process, suitable for different materials. Feed 240mm, discharge <3mm, finished product rate of 70%-90%.

Straight-through crushing chamber, large output

No partition or grate design, the crushing process is through-type crushing, large material throughput, high output, low energy consumption.

Throwing plate structure, cost saving

The throwing ribs and linings are cross-distributed, and the worn throwing ribs can be used as throwing linings to improve material utilization and reduce costs.

water-cooling structure, can break high-temperature materials

Can break high-temperature materials below 150°C, and heat-resistant bearings and grease can reach 260°C.

High efficiency and energy saving, stable operation

The equipment runs smoothly, with low noise, low vibration, and good sealing. Easy to operate, small footprint, easy to install and maintain.

The chassis can be equipped with a protective plate

Suitable for crushing high-hardness and highly abrasive materials (such as quartz, silica, river pebbles and highly abrasive dolomite), effectively preventing the chassis body from being worn.

Application

The Vertical Compound Crusher boasts strong compressive strength and adaptability, making it suitable for a wide range of production environments. It is particularly widely used in sand making production lines, aggregate plants, and cement factories, where it efficiently crushes medium-hard materials such as cement raw materials, clinker, iron ore, sandstone, dolomite, bauxite, lead-zinc ore, talc, blast furnace slag, coal gangue, phosphate rock, gypsum, and lump coal.

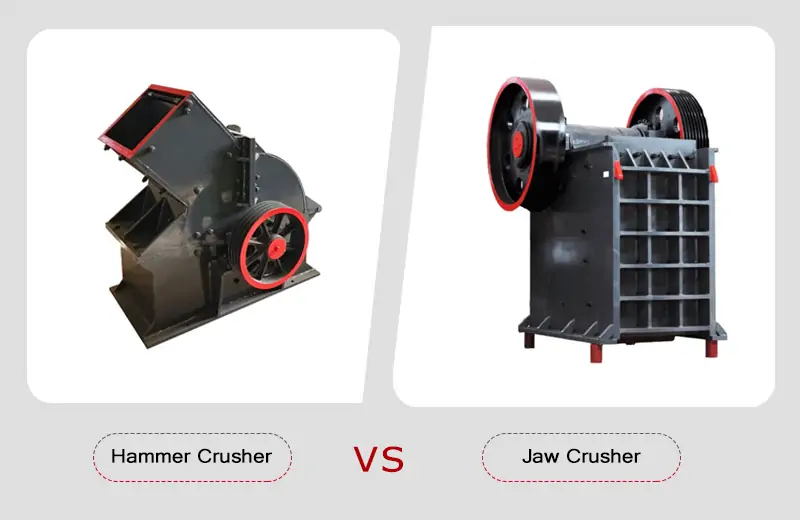

In sand production lines, the compound crusher can replace jaw crushers for crushing tasks. The processed material is then conveyed via a sand belt conveyor to a bucket elevator, which transports it to a sand screening machine for further classification or grading.

River Pebbles

Quartz

Lime Stone

Granite

Basalt

Coal Gangue

Plaster

Oil Shale

Custom Vertical Compound Crusher

Send Inquiry Now

China Vertical Compound Crusher Manufacturer and Supplier

Sanyuantang is a leading manufacturer of Vertical Compound Crushers in China, specializing in the sand and gravel crushing and screening industry for 30 years. With years of experience and a wealth of successful project cases, we offer comprehensive solutions, including crushing equipment selection, installation, commissioning, and after-sales support. Contact us today, and our team will provide you with personalized crushing solutions designed.