PE jaw rock crusher machine is a coarse crushing equipment specially designed for processing various ores, rocks and other hard materials with a compressive strength not exceeding 320MPa into a medium particle size range. This equipment usually forms a complete sand and gravel crushing production line system together with sand making machine, belt conveyor, bucket elevator, and screening machine. PE jaw crusher has high strength, reliability and durability, large crushing force and high production output.

- Model: PE/PEX

- Feed size: 125~1200mm

- Discharging particle size: 20-300 (mm)

- Production capacity: 5-800t/h/hour

- Application: Quartz, calcite, basalt, limestone, river pebble, granite, slag, marble, slag stone, gypsum, etc.

Price: US $4,000.00 -$ 18,000.00 / Set

Jaw Rock Crusher Machine Working Principle

The working principle of the PE series jaw crusher is mainly based on the flexural extrusion type crushing method. With the electric motor as the power source, the groove wheel is driven by the pulley and the V-belt to drive the eccentric shaft to rotate, so that the movable jaw reciprocates according to the predetermined trajectory, and the materials entering the crushing chamber are crushed by multiple actions such as extrusion, rubbing, and grinding, and the finished materials are discharged through the lower discharge port.

Structure

The PE jaw type rock crusher is mainly composed of a frame, an eccentric shaft, a large pulley, a flywheel, a movable jaw, a side guard plate, a toggle plate, a toggle plate back seat, a gap adjustment screw, a reset spring, a fixed jaw plate, and a movable jaw plate. Among them, the toggle plate not only supports the movable jaw, but also protects it when foreign objects that cannot be crushed enter the crushing chamber, that is, it cuts off the load by breaking itself and protects other parts from damage.

Details

Specifications

| Model | Max feeding size(mm) | Capacity(t/h) | Output size(mm) | Power(kw) | Weight(kg) |

|---|---|---|---|---|---|

| PE150×250 | 125 | 1-3 | 10-40 | 5.5 | 1160 |

| PE200×300 | 180 | 2-6 | 15-50 | 7.5 | 1240 |

| PE200×350 | 180 | 3-10 | 18-60 | 11 | 1520 |

| PE250×400 | 210 | 5-20 | 20-80 | 15 | 2572 |

| PE400×600 | 340 | 14-36 | 40-100 | 37 | 5800 |

| PE500×750 | 425 | 30-80 | 50-120 | 45 | 9000 |

| PE600×900 | 500 | 56-192 | 75-200 | 75 | 18900 |

| PE750×1600 | 630 | 110-320 | 80-235 | 110 | 29300 |

| PE900×1200 | 750 | 180-350 | 100-250 | 110 | 55000 |

| PE1200×1500 | 1020 | 400-800 | 150-350 | 160 | 101000 |

| PEX150×750 | 120 | 8-35 | 10-40 | 15 | 3350 |

| PEX250×750 | 210 | 15-45 | 15-50 | 30 | 5000 |

| PEX250×1000 | 210 | 15-50 | 20-50 | 30 | 6800 |

| PEX250×1200 | 210 | 20-70 | 20-60 | 45 | 9000 |

*Note: The output will vary depending on different materials, feed size, etc.

Different Types of Jaw Crusher Machine

Sanyuantang jaw crusher series covers a variety of models, with output ranging from 1~3 tons/hour to 400~800 tons/hour. There is always a model that can meet your production needs. Please note that the PE series is for coarse crushing and the PEX series is for fine crushing.

One of our main products is large and medium-sized jaw crushers. Jaw crushers can also be specially customized according to different functions and applications, such as fixed jaw crushers, mobile jaw crushers, and jaw crushers with vibrating screens. Request a free quote now!

Features

Deep cavity crushing, high efficiency and energy saving

The deep cavity crushing structure is optimized and designed without dead zone, which greatly improves the feeding and crushing efficiency.

Simplified structure, convenient maintenance

Following the concept of “Ease Sieve“, the overall structure is simple, easy to operate and maintain.

Flexible adjustment, one machine for multiple uses

The gasket-type discharge adjustment device is adopted, with a wide range of discharge adjustment and more flexible equipment use.

Low noise and environmental protection, dust controllable

The crushing equipment is designed in strict accordance with national environmental protection standards, with low noise and can be equipped with dust removal equipment to meet environmental protection requirements.

Heavy-duty design, stable and reliable

The heavy eccentric shaft, high manganese steel jaw plate and high-grade cast steel movable jaw assembly are processed with larger forging billets, which greatly improves the equipment’s carrying capacity and makes the operation more stable.

Centralized lubrication, worry-free maintenance

The specially designed centralized lubrication system makes component lubrication more convenient and efficient, and requires less maintenance.

Application

PE jaw crusher is mainly used for preliminary or intermediate crushing of ore or bulk materials to provide suitable particle size for subsequent processing. It is widely used in mining, smelting, construction, highway, railway, water conservancy, and chemical industries.

- Ore: such as iron ore, copper ore, lead-zinc ore, gold ore, etc.

- Rock: such as granite, marble, limestone, basalt, etc.

- Construction waste: such as concrete blocks, bricks, waste building materials, etc.

- Industrial waste: such as smelting copper slag, silicon-calcium alloy, ferrosilicon, ferrochrome, ferroboron, ferromanganese, etc.

Custom Jaw Rock Crusher

One-stop customized Crush and Screen solutions

Get a Quote

Custom One-Stop Sand Crushing And Screening Lines

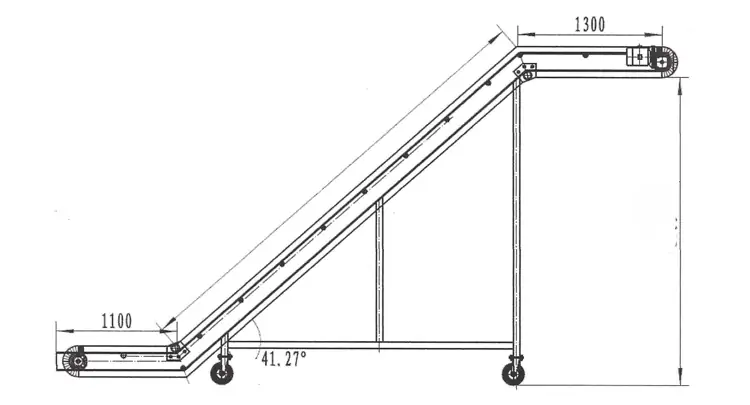

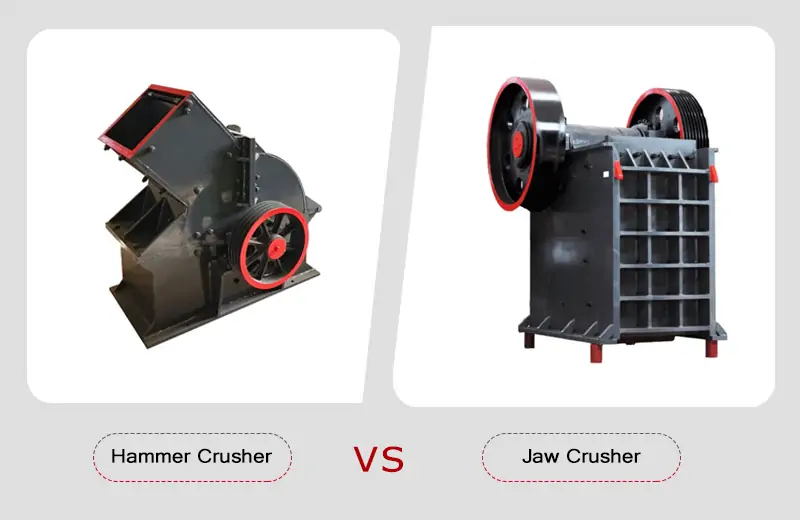

System equipment: Jaw crusher(Hammer Crusher), belt conveyor, sand making machine, bucket elevator, large swing vibrating screen

It can realize the synchronous production of machine-made sand and crushed stone. The whole production line has flexible construction and diverse output materials, which can meet the various processing requirements of customers.

China Jaw Rock Crusher Machine Supplier

Sanyuantang is China leading jaw rock crusher supplier and manufacturer, focusing on the field of sand and gravel crushing and screening for many years.

We have accumulated rich project cases and industry experience, providing customers with a full range of solutions from equipment selection, installation and commissioning to after-sales maintenance. As a professional crushing equipment supplier, we are committed to providing customers with better quality and more efficient crushing equipment and services, and promoting the development of the sand and gravel crushing and screening industry. Click to contact us, our team will quickly provide you with customized crushing or solutions.