Jaw crushers are one of the most important pieces of equipment in the mining, construction and aggregate industries, with their rugged durability and ability to handle large amounts of material. However, like any heavy machinery, equipment wear is inevitable. To ensure continued efficiency and productivity, jaw crusher parts need to be replaced regularly.

The jaw crusher parts that are replaced regularly include jaw plates, tooth plates, liners, bearings of movable and static jaws, eccentric shafts, and seals of the lubrication system. Because these parts will experience greater wear and fatigue during long-term work, especially when processing materials with higher hardness, they are more prone to damage. Regular inspection and replacement of these key parts can effectively avoid equipment failures, reduce downtime, thereby improving production efficiency and extending the service life of equipment.

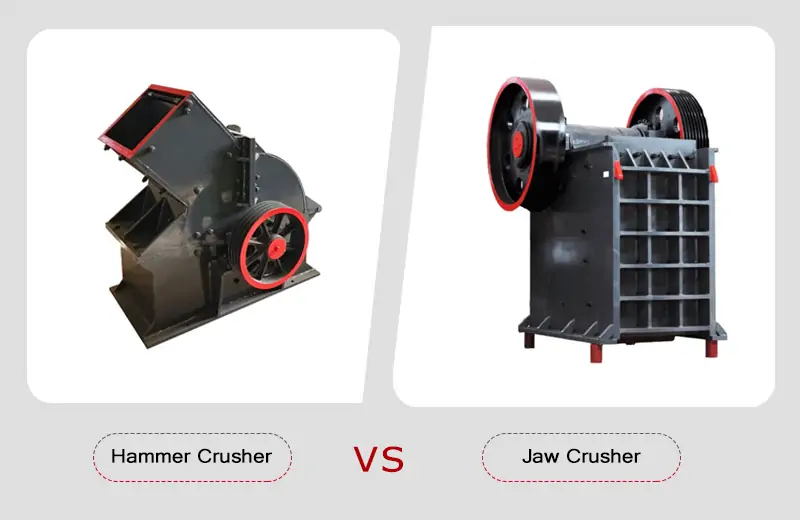

Jaw Crusher Machine Structures

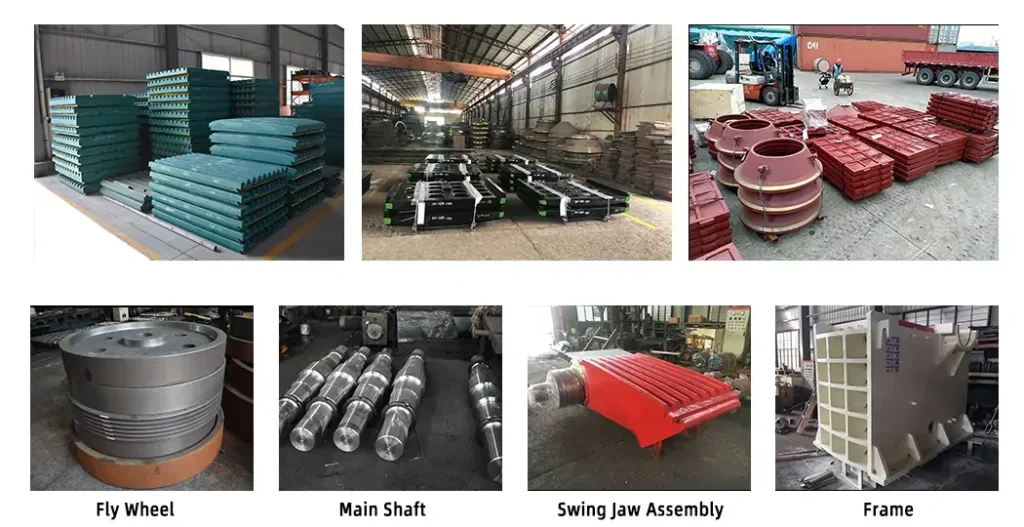

Jaw crusher is a kind of industrial crusher equipment used for coarse crushing of ore, rock and other materials. It has a compact structure design and high working efficiency. It is widely used in mining, metallurgy, construction and other industries. Its main components include frame, fixed jaw liner, suspension bearing, suspension shaft, movable jaw liner, eccentric shaft, eccentric bearing, connecting rod, flywheel, thrust plate support, front and rear thrust plates, top seat, pull rod, spring, pulley, pad, side wall liner, fixed steel plate, lifting lug (spring support plate), gasket and other parts.

Regular inspection and maintenance of these key components is the key to ensure long-term operation of equipment, improve production efficiency and reduce maintenance costs.

Jaw Crusher Parts and Their Functions

Frame (Frame)

The frame is the main structural component of the jaw crusher and is made of steel or cast iron to withstand the high pressure and forces generated during the crushing process.

Fixed Jaw (Fixed Jaw)

The fixed jaw is a fixed component mounted on the frame. It forms half of the crushing chamber and connects with the moving jaw to crush the material. It is usually made of high manganese steel to resist wear caused by contact with the material being crushed.

Moving Jaw (Swinging Jaw)

The moving jaw is mounted on the moving jaw and is driven by the eccentric shaft. This component moves back and forth in the crushing chamber, pressing the material against the fixed jaw. Like the fixed jaw, it is made of durable, wear-resistant material, usually high manganese steel.

Eccentric Shaft

The eccentric shaft is the driving force for the jaw’s movement. It is located at the top of the jaw crusher and rotates to make the swinging jaw move in a circular motion.

Eccentric Shaft Bearing

The eccentric shaft bearing supports the eccentric shaft and allows it to rotate smoothly. It reduces friction and ensures that the shaft runs with minimal wear, thereby extending the life of the jaw crusher.

Toggle Plate

The toggle plate is a key component that connects the movable jaw to the eccentric shaft. It is a safety mechanism that absorbs shock loads and protects other components such as the drive and bearings from damage when overloaded.

Toggle Plate Seat

The toggle plate seat is where the toggle plate is placed. It is used to maintain the correct position and alignment of the toggle plate and movable jaw, ensuring smooth operation and efficient crushing.

Flywheel

The flywheel helps store energy during the crushing cycle and releases energy during the return stroke of the jaw plate. It ensures smooth operation of the jaw crusher by maintaining a constant speed. The flywheel also acts as a counterweight to reduce vibration during operation.

Jaw Crusher Pulley (V-Pulley)

The pulley, also known as the V-Pulley, is mounted on the flywheel and is responsible for transmitting power from the motor to the jaw crusher. It is connected to the motor through a V-belt, allowing the machine to operate efficiently.

Spring

The spring is used to absorb shocks and provide necessary tension to certain components such as the toggle plate. In some jaw crushers, the spring helps adjust the discharge opening and can be used to apply additional pressure to the material being crushed.

Discharge opening

The discharge opening is the gap between the fixed jaw and the moving jaw. The size of this gap determines the output size of the crushed material. It can be adjusted to accommodate different material sizes and achieve the desired output level.

Side guards (side liners)

The side guards or side liners are located on the sides of the jaw crusher to protect the frame from wear caused by the crushed material. They help extend the life of the machine by preventing direct contact between the frame and the material.

Bearings

The bearings in the jaw crusher are mainly used to support the movement of the eccentric shaft, flywheel and other rotating parts.

V-belts

V-belts are used to connect the motor to the jaw crusher, transmitting power and making the crusher operate.

Liners (side liners)

The liners are installed on the sides of the jaw crusher to protect the frame from wear. They are made of durable materials, such as high manganese steel, and help reduce the impact of the crushed material on the machine.

Customize Jaw Crusher Wear Parts: Applicable to multiple international brands

we produce jaw crusher spare parts that are compatible with many internationally renowned brands, including Metso, Sandvik, Terex, Nordberg, Trlo, Symons, Svedala, Pegson, Telsmith, Shanbao, Shibang, Gatory, etc., which can meet the needs of different equipment.

Available Models for Jaw Crusher Parts

| Product Series | Models |

|---|---|

| PE & PEX Series | PE150*250, PE200*300,PE250*400,PE400*600,PE500*750, PE600*900, PE750*1050, PE900*1200, PE100*1200, PE1200*1500, PE1500*1800, PEX250*750, PE250*1000, PE250*1200, PE300*1300, PE10″*16″ |

| CJ Series | CJ211, CJ409, CJ411, CJ412, CJ612, CJ613, CJ615, CJ8115 |

| C Series | C80, C96, C106, C116, C120, C130, C150, C160, C200 |

| CT & CTHT Series | CT1030, CT1040, CT1048, CT1252, CT2036, etc. |

Customize Jaw Crusher Parts Advantages

- Accurate dimensions to ensure complete consistency with original part numbers and design drawings.

- Effectively reduce jaw crusher downtime and improve production efficiency.

- With higher cost-effectiveness, helping you save 40-60% of costs.

- Adopting advanced manufacturing technology, strictly following the requirements of original process and drawings.

Jaw Crusher Parts Supplier and Manufacturer

Sanyuantang is a leading manufacturer and supplier of crushing equipment, vibrating screens and conveying equipment in China, with advanced production equipment and technology, strict quality control system, and rich accessories supply. We are committed to providing high-quality cast liners and jaw crusher wear parts to meet your highest requirements for equipment performance and durability. If you need to customize or replace jaw crusher parts, please feel free to contact us.

The following is the processing flow of our factory:

1.Process design

2.Pattern Making

3.Modeling

4.Coating

5.Casting

6.Pouring

7.Clean

8.Heat Treatment

9.Grinding workshop

10.Machining

11.Inspection

12.Packing&Delivery