The double vibration source gyratory screener is a large-capacity, high-precision screening equipment developed and customized for the sand and gravel industry, based on the single-vibration source square swing screen and with comprehensive customer on-site application feedback for technical upgrades.

- Model: FYBS-2040

- Mesh Size: 2-180 mesh

- Capacity: 1- 25 ton/h

- Applicable materials: Quartz sand, silica sand, fracturing sand, machine-made sand, plate sand, ceramsite sand, calcite, mica powder, calcium carbonate, bentonite, petroleum coke, etc.

Price: $18900.0 – 29600.0 / Set

Gyratory Screener Introduction

This equipment integrates multiple motion trajectory modes, and the processing capacity and screening accuracy of a single device are 2 times higher than that of the same type of single-vibration source equipment, with an output of up to 30 tons per hour.

The double vibration source gyratory screener entire device has been granted U.S. patents and multiple domestic patents in 2021, and is the leader in industry technology. In terms of screening levels, the dual-vibration source gyratory screener usually adopts a 10-layer structure design and can complete fine screening tasks of 6 different granularity levels at one time.

Gyratory Screener Features

Multi-layer grading design

The multi-layer grading design can accurately screen and grade materials of different particle sizes.

One machine is divided into two groups

One machine is equivalent to multiple machines, which is equivalent to the efficiency of multiple ordinary screening equipment, doubling the output.

adopts riveted fully enclosed structure

Effectively prevent dust from flying. At the same time, the screen machine has small vibration and low noise, which meets environmental protection requirements.

Flexible screening, longer life

Adopting flexible screening technology, the acceleration is 4-5 times lower than that of ordinary vibrating screens, which prolongs the service life of the equipment and reduces maintenance costs.

Innovative grid and mesh design

The unique grid and mesh installation method make the mesh replacement more convenient and simple to operate.

Large-scale electrostatic spraying process

Makes the appearance of the equipment more beautiful, enhances wear resistance and rust resistance, and prolongs the service life of the equipment.

Working Principle

The double vibration source gyratory screener adopts an elliptical reciprocating motion with a continuously decreasing transverse diameter, and has higher processing capacity and screening efficiency than general inertial vibration screens.

During use, the movement trajectory and retention time of the material on the screen surface can be adjusted by increasing or decreasing the spindle speed and the size of the exciting force within a certain range, so that the material follows a movement trajectory with a nonlinear curve of speed and acceleration in a limited screening space, increasing the contact rate between the material and the screen surface, thereby effectively improving the screening rate and ensuring the efficiency and accuracy of the screening process.

Structures

The double-vibration source gyratory screener adopts a hanging structure and is mainly composed of several key components:: inlet for feeding material, screening box, driving unit, sieve frames, supporting frames, vibration damping devices, and outlet for discharging material. The following is gyratory screener diagram:

Details Show

Specifications

| Model | Screen size | Screening area | Screen inclination | Layers | Power | Number of turns | Case travel |

|---|---|---|---|---|---|---|---|

| FYBS2040 | 2.0*4.0 m | 8-9 m2 | 5-8 | 1-10 | 7.5 | 180-260 | 25-60 mm |

Different Models of Double Vibration Source Gyratory Screeners

The double vibration source gyratory screener can be customized to design the number of screening layers and the configuration of the discharge port according to the required particle size. For details, please refer to the attached figure for examples:

Application

The gyratory swing screen is mainly used for screening materials such as petroleum fracturing sand, quartz sand (silica sand), machine-made sand, plate sand, glass sand, ceramic sand, drying sand, pearl sand, mica powder, garnet, brown corundum, recarburizer, calcium carbonate powder (limestone), petroleum coke, industrial salt, bentonite, dry mineral powder, talcum powder, etc.

Oil Fracturing Proppant

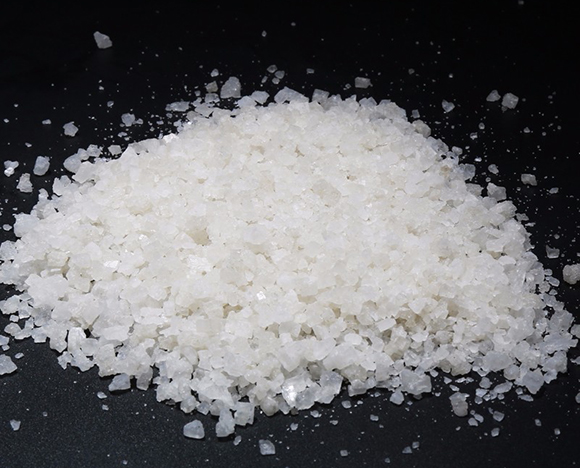

Oil Fracturing Proppant Quartz sand

Quartz sand Ceramic Sand

Ceramic Sand Perlite

Perlite Petroleum Coke

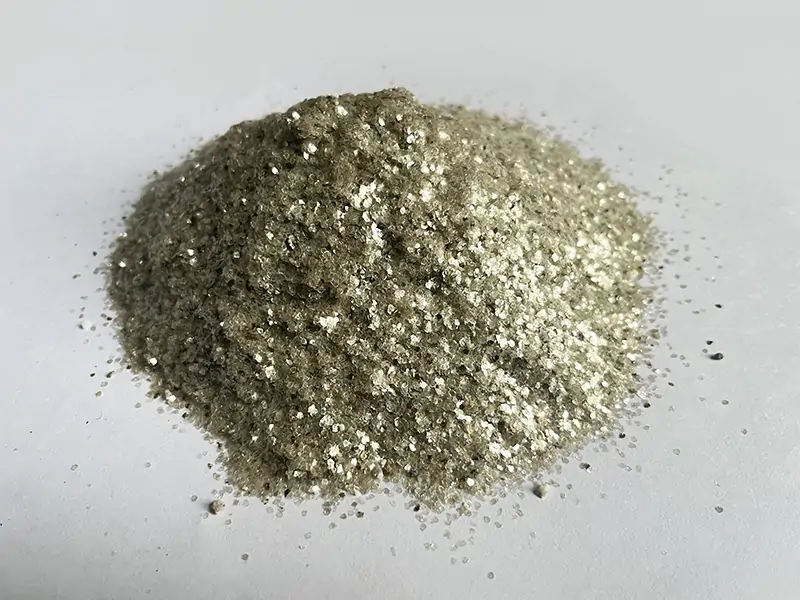

Petroleum Coke Mica Powder

Mica Powder Calcium Carbonate

Calcium Carbonate Industry Salt

Industry Salt Cork powder

Cork powder Soda Ash

Soda Ash

Videos

Cases

In the field of fine screening of sand and gravel, we have rich project experience, especially for the screening of quartz sand and fracturing sand. We have tailored many efficient sand screening production lines for many customers. If you also want to customize a one-stop sand screening solution, please feel free to contact our team to get the details and quotation of the gyratory screener. The following are actual feedback photos of the customer site for your reference:

Custom Your Production Line

One-stop customized screening solutions

Submit a Quick Quote

Gyratory Screener Manufacturer

We are a professional gyratory screener manufacturer, focusing on overall screening and conveying solutions for 30 years. With continuous research and innovation in technology, we have successfully developed and launched a number of efficient gyratory screener products. So far, gyratory screener equipment has won more than 40 patent certificates.

- In 2017, we upgraded the conventional screening product process, independently developed the single vibration source gyratory screener, entered the market, and obtained multiple patents.

- In 2019, we optimized the general-purpose “square gyratory screen” and innovated the “one-line arrangement” discharging method.

- In 2020, we innovatively launched the “double-channel” and “double five-layer” square swing screens, and the linear swing screen was patented.

- In 2021, we developed the “double vibration source gyratory screener” to double the screening efficiency and obtained multiple patents.

- In 2022, we obtained multiple certifications such as “high-tech enterprise”. In the same year, the square gyratory vibrating screen obtained a US patent.

- In 2023, gyratory screener has covered many quartz sand and fracturing sand production lines across the country. The company successfully developed the swing probability screen and obtained a patent.

- In 2024, the “Ease Sieve” brand concept was established, and the four-vibration source square gyratory screener entered the marke.