“The silica sand vibrating screen is great. It not only has high screening accuracy, but also has large output, which greatly improves our production efficiency.” Abhishek said – manager of the Indian glass manufacturing industry.

Overview

As one of the leading companies in the glass manufacturing industry in India, it has been committed to providing the highest quality glass products since its inception in 2005. Silica sand is one of the main raw materials for glass production due to its high silica content and high purity. To enhance the transparency, clarity, and chemical stability of glass, silica sand is often finely screened to remove impurities such as clay, organic matter, and iron oxides before manufacturing.

Silica sand vibrating screens are also used to control the particle size distribution of silica sand used in glass manufacturing. Different types of glass require specific particle size ranges to achieve the desired optical properties, strength, and surface finish.

In glass manufacturing, in addition to silica sand, various raw materials such as soda ash, limestone, and cullet (recycled glass) are mixed in precise proportions to form a glass batch. The preparation of these raw materials requires grading and screening to ensure uniform particle size distribution and improve batch uniformity.

Customer requirements

Material: Silica sand

Material size: 1.18/0.8/0.6/0.3/0.15mm

Feeding size: 0-2mm

Particle size distribution: +1.18mm accounts for 23%, 0.8-1.8mm accounts for 20%, 0.6-0.8mm accounts for 14%, 0.3-0.6mm accounts for 14%, 0.15-0.3 accounts for 9.5%, -0.15mm accounts for than 19.5%

Accuracy requirement: 95%

Production requirements: 70 tons/hour

Solutions

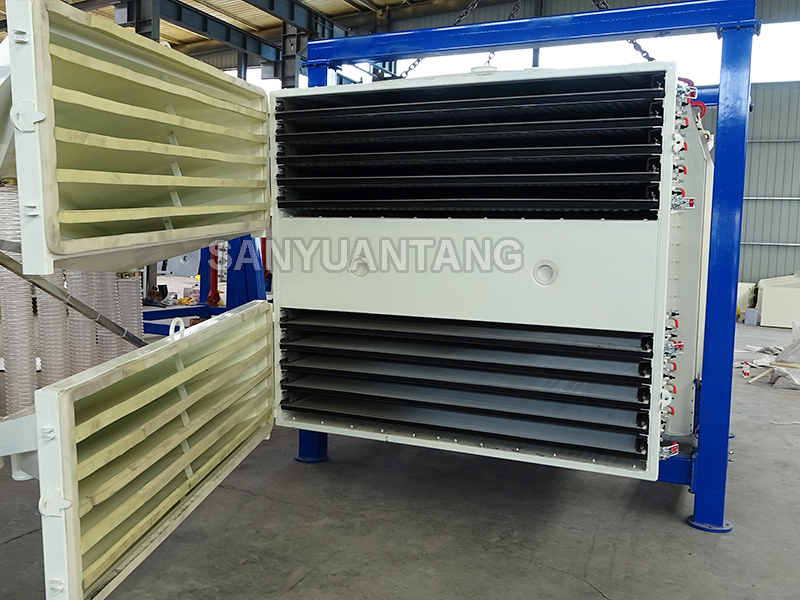

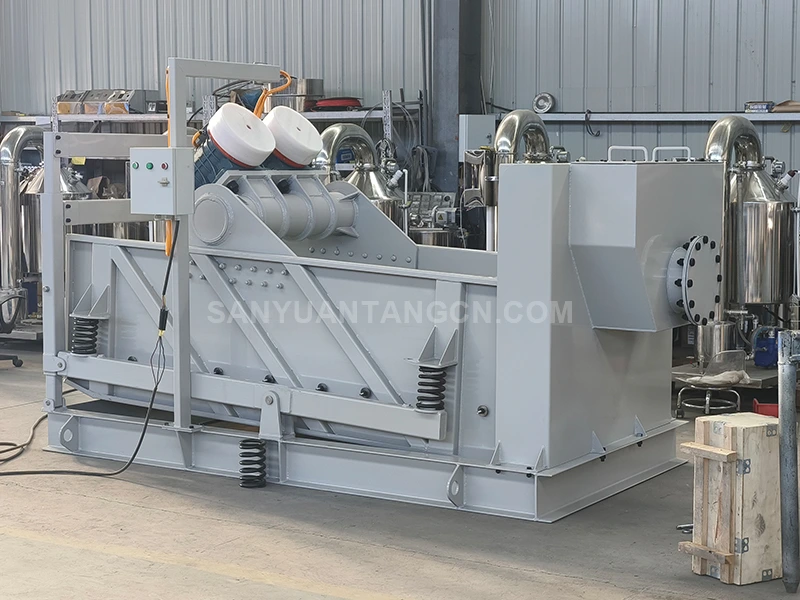

- Product: Gyratory Sifter

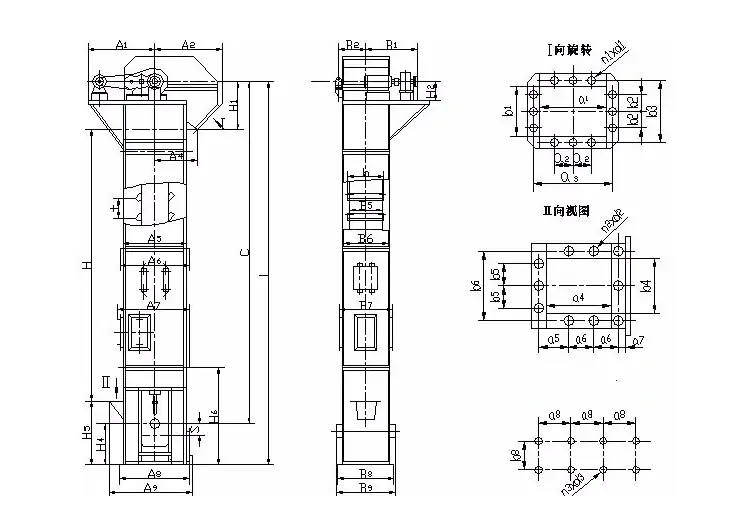

- Model: FYBS2040

- Layers: 5*2 (6 discharge openings in the upper row and 6 discharge openings in the lower row)

- Mesh: 30-100 Mesh

- Motor: Medium vibration motor

- Capacity: 15 Tons/hour

- Quantity: 5 Sets

- Location: India

- Time: September,2021

Advantages of Silica sand vibrating screen

- Exquisite design and unique structure are beneficial to extending the service life of the equipment and reducing operation and maintenance costs.

- Using low frequency and small load operation, the power system has little effect on equipment and materials.

- The installation is simple, the screen is easy to replace, the maintenance is convenient, the power consumption is low, and the operation noise is low.

- Large processing capacity, high screening efficiency, and the screening accuracy of the swing screen are generally above 95%.

- Fully enclosed structure, good sealing effect, and no dust pollution.

- It can meet the dry and wet classification requirements of general materials.

- Equipped with a bouncing ball screen cleaning device, which can effectively solve the problem of screen surface clogging.

outcome

During the communication process, the customer was very satisfied with our customized Silica Sand vibrating screen solution, price, and timely response service. On September 4, 2021, the Indian Glass Manufacturing Company ordered 5 silica sand vibrating screens from Sanyuantang. In addition, we have equipped customers with sufficient spare parts for wearing and also provided two screens as gifts. After 15 days, we completed production and shipment.

After the customer received the goods, the assembly of the silica sand vibrating screen took very little time and went smoothly. Because all parts of the gyratory screen are modular, installation can be completed quickly by following the steps. So far, all devices are working fine. We will continue to provide lifelong service to this customer.