Bucket elevators are essential in industries such as agriculture, mining, construction, and food for the vertical transport of bulk materials. Operating bucket elevators at optimal capacity is essential to maintaining efficiency and productivity. In this article, we will walk you through the steps to accurately calculate bucket elevator capacity so that you can make an informed decision for your operation.

Understanding Bucket Elevator Capacity

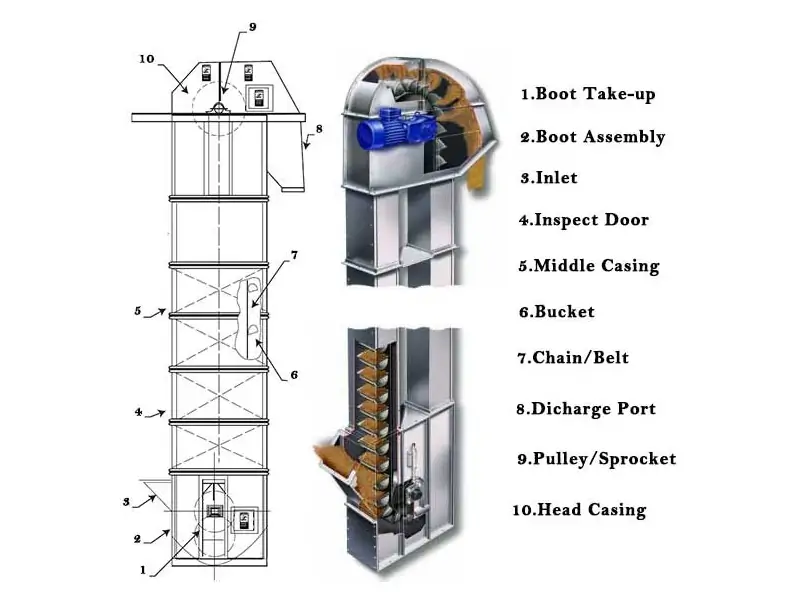

Before making a calculation, it is important to understand what bucket elevator capacity means. Capacity refers to the amount of material a bucket elevator can transport in a given time frame, usually measured in tons per hour (tph) or cubic feet per hour (cfh). Several factors affect this capacity, including bucket size, belt speed, material characteristics, and the design of the elevator.

Key Factors Affecting Bucket Elevator Capacity

- Bucket Size and Shape: The size and shape of the bucket directly affects the amount of material that can be carried. Larger buckets can hold more material, but they also require a more powerful system to handle the increased load.

- Belt Speed: The speed at which the belt moves determines how fast the material is transported. Faster speeds can increase capacity, but can also cause spillage or material degradation if not managed properly.

- Material properties: The type of material being transported (density, particle size, and flowability) affects how much it can carry and how efficiently it can be moved.

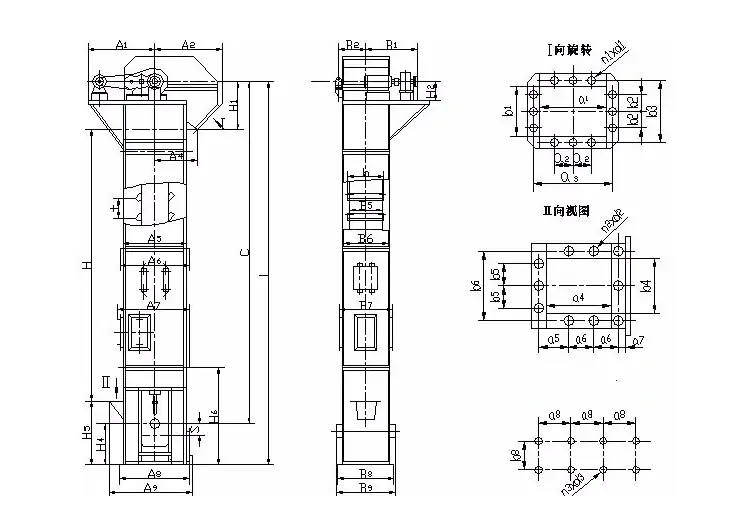

- Elevator design: The design of the elevator, including the spacing between the buckets and the angle of the elevator, also plays a role in determining capacity.

Step-by-step calculation of bucket elevator capacity

To calculate the capacity of a bucket elevator, follow these steps:

Step 1: Determine bucket capacity

First, calculate the capacity of a single bucket. This can be done using the volume formula for the bucket shape. For a standard rectangular bucket, its volume (V) is:

V=Length x Width x Height

For cylindrical buckets, use the formula for the volume of a cylinder:

V=π x r² x Height

where r is the radius of the bucket.

Step 2: Calculate Material Density

Next, determine the bulk density of the material being transported. Bulk density (ρρ) is the weight of the material per unit volume, typically measured in pounds per cubic foot (lb/ft³) or kilograms per cubic meter (kg/m³).

Step 3: Determine Belt Speed

Measure the speed of the belt in feet per minute (fpm) or meters per second (m/s). This can usually be obtained from the elevator’s specifications or by using a tachometer.

Step 4: Calculate Bucket Spacing

Bucket spacing is the distance between the centers of two consecutive buckets. This spacing affects how many buckets will pass a given point in a certain time frame.

Step 5: Compute Capacity

Finally, use the following formula to calculate the bucket elevator capacity (C):

C=(V × ρ × S × 60)/D

where:

V = Bucket volume (ft³ or m³)

ρ = Material bulk density (lb/ft³ or kg/m³)

S = Belt speed (fpm or m/s)

D = Bucket spacing (ft or m)

60 = Conversion factor to get the capacity in tons per hour (tph)

Example Calculation

Let’s say you have a bucket elevator with the following specifications:

Bucket volume (V) = 0.1 ft³

Material bulk density (ρ) = 50 lb/ft³

Belt speed (S) = 100 fpm

Bucket spacing (D) = 1 ft

Plugging these values into the formula:

C=(0.1 × 50 × 100 × 60)/1=30,0001b/h

To convert to tons per hour (tph):

C=30,000/2,000=15tph

Conclusion

Accurately calculating the capacity of your bucket elevator is essential to optimizing your operating performance and efficiency. By understanding the key factors and following the step-by-step calculation process outlined above, you can ensure your bucket elevator meets your material handling needs.

If you have any additional questions or need assistance with your bucket elevator system, please feel free to contact us. Our team of experts will help you achieve optimal operating performance. Contact us today to learn more!