Bucket elevators are essential machines in industries that require vertical transport of bulk materials. From agriculture to mining and construction, these devices play a vital role in efficiently transporting materials such as grains, powders, and pellets. If you want to know more about the working principle of bucket elevators, please read the article carefully and you will gain a lot.

What is a bucket elevator?

Bucket elevator is a continuous conveying equipment used for vertical or near-vertical conveying of bulk materials. His main function is to move materials vertically or at a steep incline. It consists of a series of buckets connected to a belt or chain that rotates around two pulleys or sprockets, one at the bottom and one at the top. The bucket scoops up the material from the lower layer, transports it to the top, and discharges it to the desired location.

Key Components of Bucket Elevator

1. Buckets: These are containers that hold and transport materials. They come in various shapes and sizes, such as deep buckets, shallow buckets, triangular buckets, etc., depending on the type of material being handled.

2. Belt or chain: The bucket is attached to the belt or chain, which acts as the drive mechanism to move the bucket.

3. Pulleys or sprockets: Located at the top and bottom, they guide the belt or chain and keep the system moving.

4. Inlet: The point where material is fed into the elevator.

5. Outlet: The point where material is discharged after being lifted.

6. Drive: Provides the power to move the belt or chain.

7. Tensioner: Keeps the traction member properly tensioned to prevent slipping or derailment

8. Enclosure: Closes the system to prevent material spillage and ensures safety.

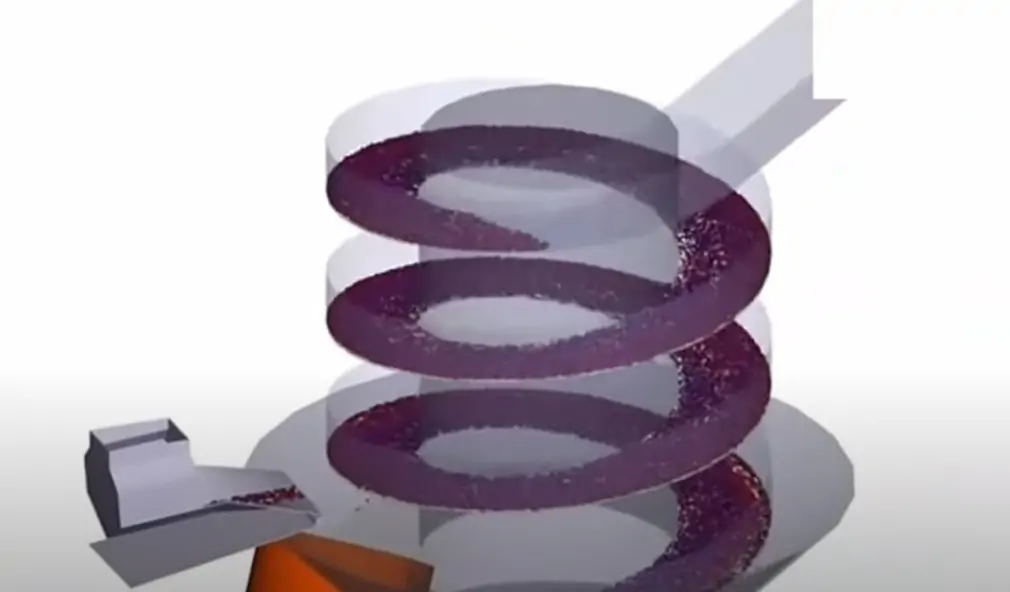

How does a bucket elevator work?

The operation of a bucket elevator can be divided into three main stages:

1. Loading

Material is fed into the elevator through an inlet at the bottom (bucket section). The bucket is attached to a moving belt or chain, which scoops up the material as it passes through the bucket. There are two feeding methods: digging and injection. The digging method is suitable for powdery and small particles, and the injection method is suitable for large and abrasive materials.

2. Lifting

After the hopper is filled, it is transported upward by a belt or chain. The closed shell ensures that the material remains safe and prevents dust or spillage during the lifting process. The speed of the belt or chain can be adjusted to handle different volumes of material. The running speed should be moderate. Too fast may cause material to be thrown, and too slow will affect efficiency.

3. Discharging

At the top of the elevator, the hopper reaches the head pulley or sprocket. As they rotate on the pulley, the material is discharged from the hopper due to centrifugal force or gravity. The material is then discharged through the outlet, ready for the next stage of processing or storage.

4. Return

Empty bucket return: The empty bucket after unloading goes down with the traction member and returns to the bottom, ready to be loaded again.

5. Circular operation

Continuous cycle: The hopper is constantly circulating to achieve continuous conveying of materials.

Advantages of using bucket elevators

- Efficiency: Bucket elevators operate continuously and can transport materials uninterruptedly, improving efficiency. Because of their large capacity and diverse bucket designs, they can carry a wide variety of materials, greatly improving conveying efficiency.

- Space saving: Its vertical design minimizes the floor space requirements.

- Versatility: They can transport a variety of materials, such as powder, granules, blocks, etc.

- Durability: Bucket elevators are designed to withstand heavy-duty use, are durable, simple in structure, have a low failure rate, stable operation, and extremely low maintenance costs.

- Safety: The enclosed design reduces dust and prevents material spillage, ensuring a cleaner and safer working environment. At the same time, it is equipped with a variety of safety devices, such as overload protection, emergency shutdown, etc. So the operation is safe, the operation is smooth, and the risk of operators is reduced.

Application of bucket elevators

Bucket elevators are widely used in the following industries:

- Agriculture: used to transport grain, seeds and fertilizers.

- Mining: used to transport ore, coal and minerals.

- Construction: used to handle cement, sand and aggregates.

- Food Processing: Used to convey flour, sugar, and other foods.

Conclusion

Bucket elevators are a simple but highly effective solution for vertical material handling. By understanding their components and working processes, it is easy to see why they are popular across industries. Whether you are transporting grain on a farm or cement on a construction site, bucket elevators ensure efficient, reliable, and safe material transportation. If you are looking for a cost-effective way to simplify your material transportation problems, please contact us. We have a professional team to provide you with a more complete solution. If you have questions about the operation and use of bucket elevators, we also have detailed operating manuals and training programs for your reference.

Related Articles

- What is a Bucket Elevator?

- How To Calculate Bucket Elevator Capacity

- 3 Common Types Of Bucket Elevator, Advantages And Disadvantages

- Stainless Steel Bucket Elevator In Food Industry

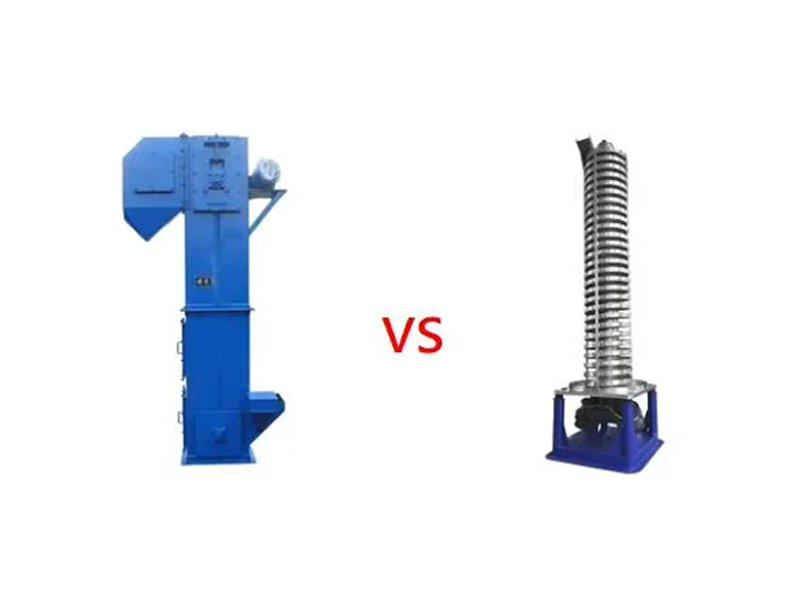

- Vertical Vibrating Elevator vs Bucket Elevator: How to Choose?

- How Does a Vibrating Spiral Conveyor Work?