Vertical material conveying is a key aspect of industrial production in many industries. Vertical vibrating elevator and bucket elevators are two common types of conveying equipment. Although they are both used to convey materials vertically, there are significant differences in their definitions, structures, operating principles, features and applications. This article will analyze both types of equipment in depth to help you choose the most appropriate solution for your specific needs.

Bucket Elevator Conveyor

Vibrating Spiral Elevator

Definition

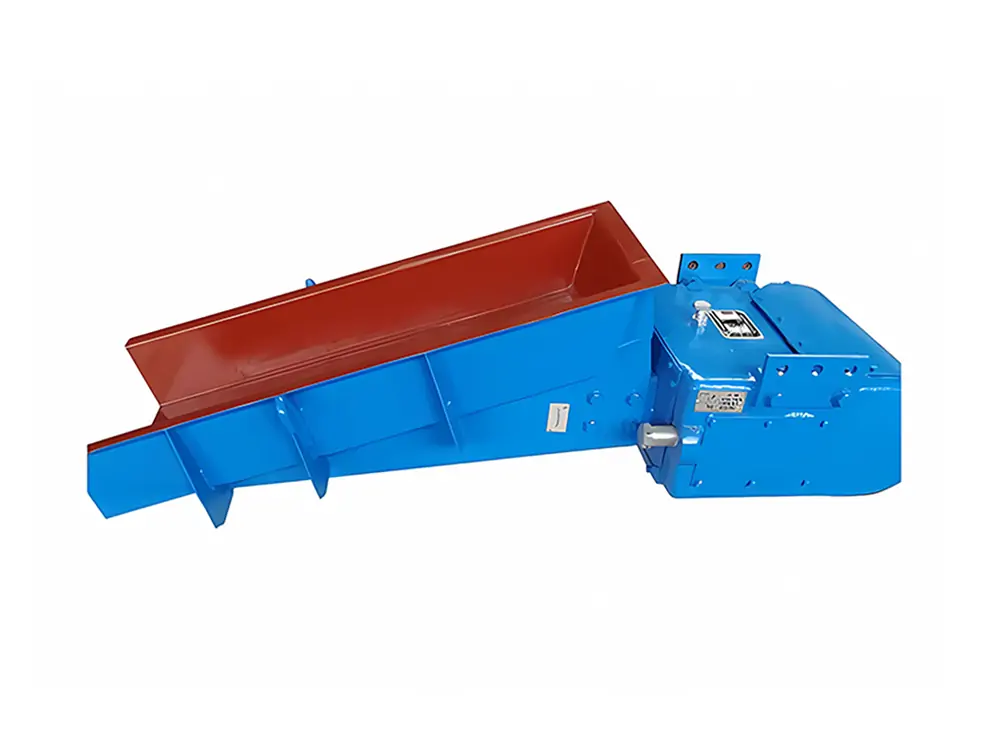

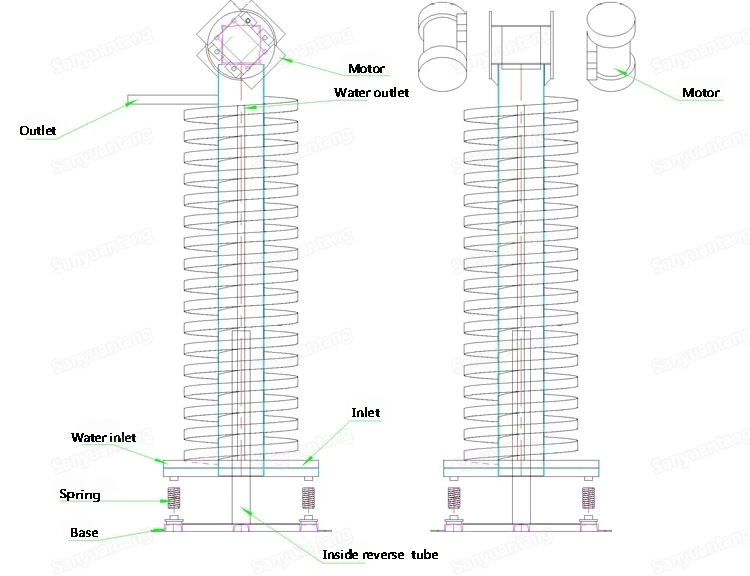

Vertical Vibrating Elevator

It is a kind of equipment that uses double vibrating motors as the vibration source and conveys materials upward or downward through vibration. It can not only lift materials vertically, but also complete the drying and cooling functions simultaneously, which is very suitable for handling lumpy, powdery and short-fibrous solids in a compact space.

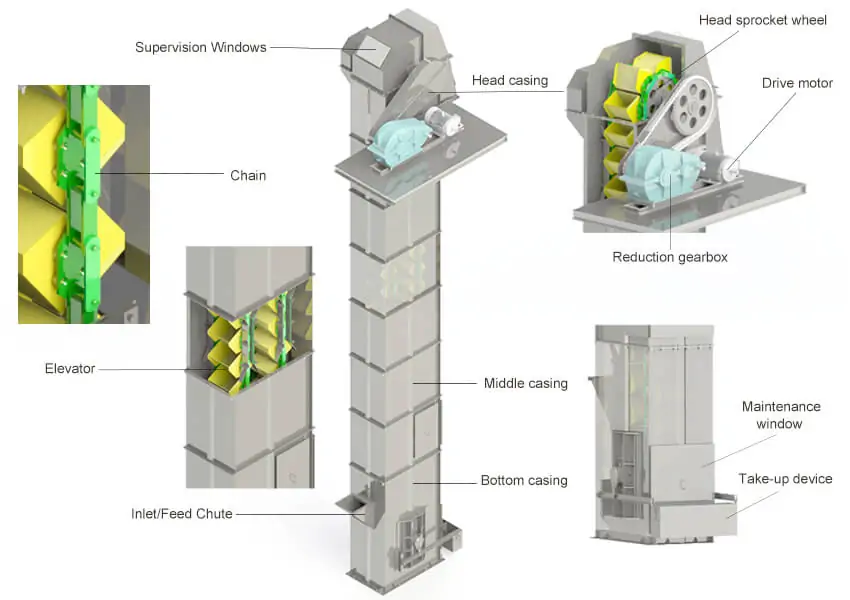

Bucket Elevator

It is a kind of mechanical equipment that shovels, handles and discharges materials vertically through a hopper fixed on a belt or chain. It is widely used for conveying bulk materials, including heavy or abrasive materials, and is suitable for vertical lifting with high capacity and large height.

Structure

Vertical vibrating elevator

- It is composed of lifting trough, vibrating motor, vibration damping system and base.

- Simple structure, easy maintenance, quantitative delivery of materials, continuously adjustable conveying capacity.

- Divided into open and closed two kinds of structure, according to user needs for special design.

Bucket elevator

- It consists of a series of hoppers mounted on belts or chains, which run on pulleys or sprockets.

- It consists of a guide section for loading, a vertical housing for lifting and a head section for unloading.

- More space is required due to the vertical housing and hopper arrangement.

Principle of operation

Vertical Vibrating Elevator

- Adopting vibration motor as the vibration source, two vibration motors are fixed on the lifting chute at a certain cross angle for reverse self-synchronized rotation.

- The centrifugal force generated by the rotation of the eccentric block causes the material to be thrown up and move upward in the lifting tank, and at the same time, fully contact with the air to realize the function of lifting, drying and cooling.

- It is suitable for vertical conveying of powdery, lumpy and short-fibrous solid materials (except for viscous or easily caked materials).

Bucket Elevator

- The material is scooped up from the bottom storage area through the hopper and lifted to the top with the conveyor belt or chain.

- After winding around the top drive wheel, the hopper turns downward and dumps the material into the designated receiving chute.

- It is suitable for efficient vertical conveying of powder, granular and bulk materials.

Features

Advantages of Vertical Vibrating Elevator

- Multi-functionality: not only realizes vertical lifting of materials, but also synchronously completes drying and cooling to meet a variety of process requirements.

- High-efficiency performance: vertical lifting height up to 6 meters, conveying capacity up to 4 tons / hour, suitable for medium and high strength material conveying.

- Bi-directional conveying: supports upward lifting and downward conveying of materials, flexible operation and strong adaptability.

- Environmental protection design: the closed structure effectively prevents dust diffusion and harmful gas spillage, in line with environmental protection requirements.

- Simple structure: compact structure, space-saving, fewer parts, easy to maintain.

Advantages of bucket elevator

- High efficiency and energy saving: small driving power, adopting inflow feeding and induced discharging, there is almost no return and digging phenomenon in the process of material lifting, which reduces the ineffective power.

- Wide applicability: It is suitable for powder, granular and bulk materials, including heavy or abrasive materials, with strong adaptability.

- Stable and reliable operation: advanced design and precision processing technology ensure stable operation of the equipment, with more than 20,000 hours of trouble-free operation.

- Large height and large capacity lifting: the range of lifting height is usually 5-40 meters, and the lifting capacity can reach 25-148 m3/hour, which meets the needs of various industrial scenarios.

Applications

Vertical Vibrating Elevator

Applicable materials: lumpy, powdery and short-fiber solid materials (except those with high viscosity or easy to caking).

Mining, metallurgy, machinery, building materials, chemical industry, rubber, medicine, electric power, grain and other industries.

Suitable for material conveying scenarios that require drying, cooling or environmental protection treatment.

PP plastic granules

PP plastic granules Masterbatch

Masterbatch PVC resin powder

PVC resin powder Xylitol

Xylitol Carbon particles

Carbon particles Chicken Essence

Chicken Essence Chinese Medicine Granules

Chinese Medicine Granules Cereal Grains

Cereal Grains

Bucket Elevator

Applicable materials: powder, granular and bulk materials, including heavy or abrasive substances.

Agriculture: Elevation of materials such as grain and feed.

Mining: transportation of coal, ore and other materials.

Building materials: vertical lifting of cement, gravel and other materials.

Chemical industry: transfer of materials such as fertilizers, plastic granules, etc.

Quarz Sand

Quarz Sand Ceramic Sand

Ceramic Sand Refractory Materials

Refractory Materials Clay

Clay Steel Grit

Steel Grit Hardware Accessories

Hardware Accessories Grains

Grains

Conclusion

The choice between a vertical vibratory elevator or a bucket elevator depends on your specific material handling needs:

- A vertical vibratory elevator is ideal if you need a compact, low-maintenance machine for materials that are light, friable, or need to be dried and cooled.

- A bucket elevator is a more suitable solution if you are handling heavy, abrasive, or bulk materials and need a high-capacity, large-height vertical lift.

By understanding the definition, construction, operating principles, features and applications of both types of equipment, you can make an informed choice that optimizes productivity and reduces costs. For professional selection advice or customized solutions, please contact our technical team and we will provide you with the best service!

Related Articles

- What is a Bucket Elevator?

- Bucket Elevator Installation and Operation Instructions

- 3 Common Types Of Bucket Elevator, Advantages And Disadvantages

- Stainless Steel Bucket Elevator In Food Industry

- How Does a Vibrating Spiral Conveyor Work?

- How To Clean The Spiral Conveying Layer When Changing Materials?

- How To Maintain A Vibrating Spiral Elevator Conveyor?

- Vibrating Spiral Elevator For Cooling Plastic Pellets