In industrial production, vibrating feeder is the key equipment for material conveying and quantitative feeding. According to the different power source, vibrating feeder is mainly divided into electromagnetic vibrating feeder and motor vibrating feeder. Although the two functions are similar, but in the structure, working principle, performance characteristics and application scenarios have obvious differences. In this article, we will compare these two types of equipment to help you choose the most suitable feeder according to the actual needs.

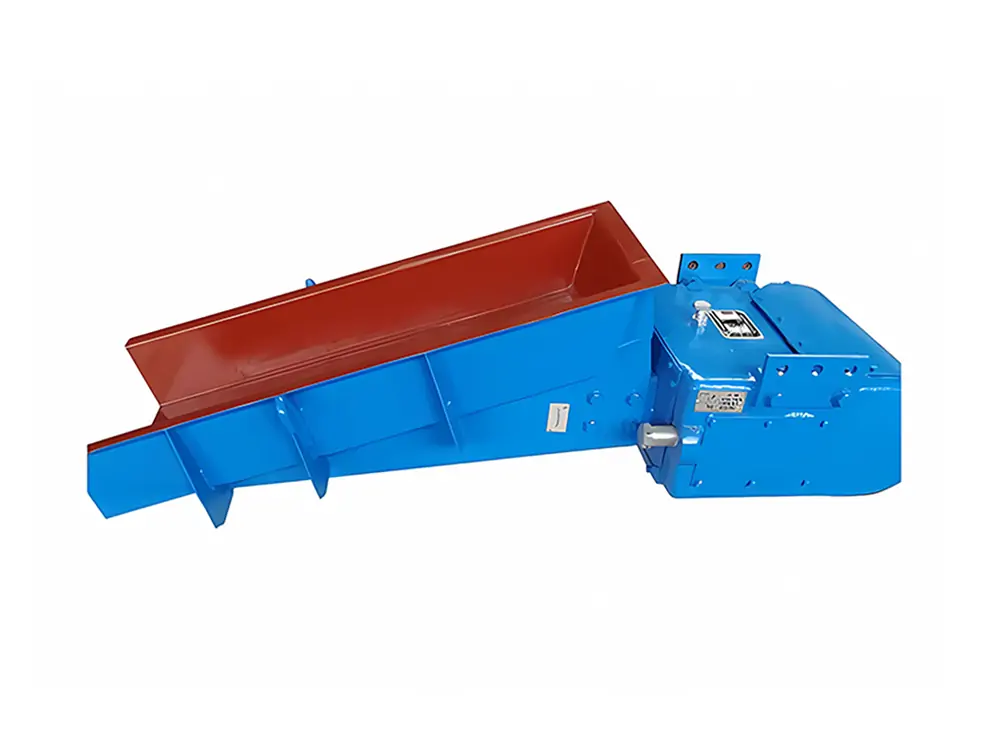

Electromagnetic Vibrating Feeder

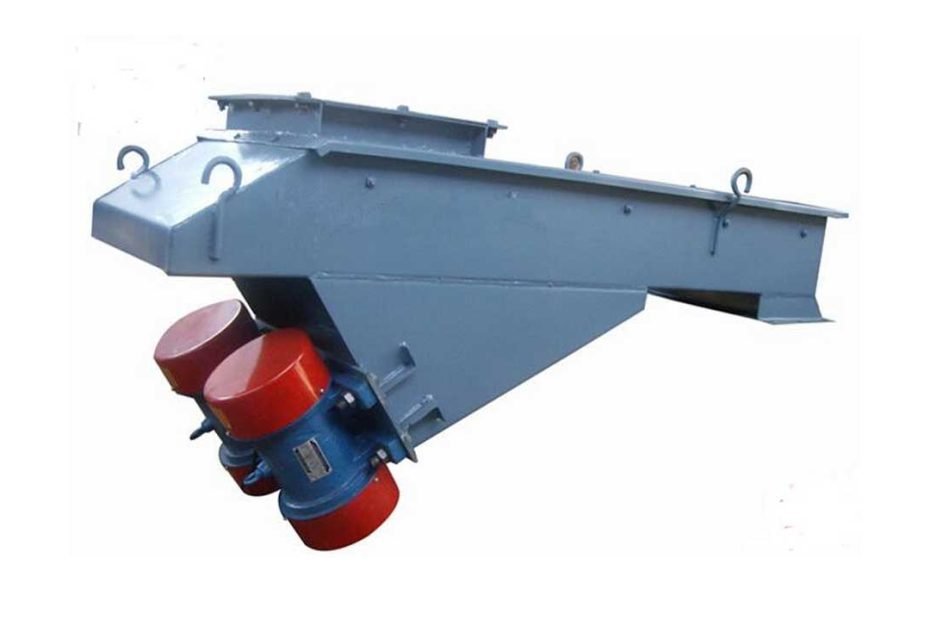

Double Motors Vibrating Feeder Conveyor

Structure comparison

Electromagnetic vibrating feeder

- Core components: electromagnetic exciter, feeding trough, elastic components (such as springs).

- Structural characteristics: compact structure, fewer moving parts, mainly driven by electromagnets and coils, the overall design is more precise.

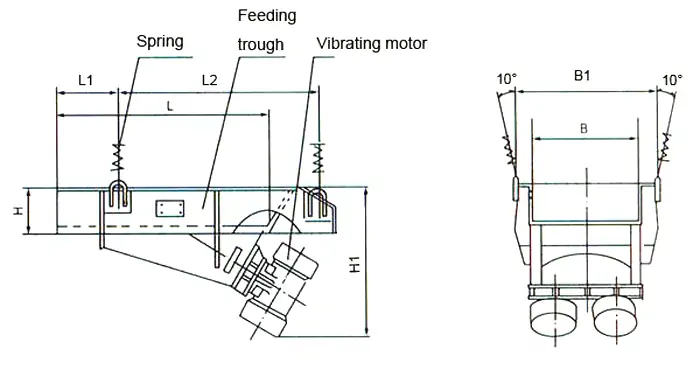

Motorized Vibrating Feeder

- Core components: vibration motor, feeding trough, shock absorbing spring.

- Structural characteristics: relatively simple structure, mainly driven by vibration motor, more mechanical parts, but easy maintenance.

Power source comparison

Electromagnetic vibrating feeder

- Power source: driven by electromagnetic force, through the electromagnet and coil to produce excitation force.

- Vibration frequency: higher, usually 1500 times / min (half-wave rectification after crossover frequency) or 3000 times / min (half-wave rectification).

- Amplitude: smaller, usually 1.5-3mm, suitable for fine feeding.

Motor vibrating feeder

- Power source: motor-driven, generating excitation force through vibration motor.

- Vibration frequency: lower, usually 700-3000 times/minute.

- Amplitude: larger, usually 2-5mm, suitable for large flow feeding.

Comparison of working principle

Electromagnetic vibrating feeder

The working principle of electromagnetic vibrating feeder is based on electromagnetic induction. When the electromagnetic exciter is energized, the electromagnet generates periodic magnetic force, which drives the feeding trough to work in a low critical resonance state. The trough body reciprocates at a certain inclination angle, so that the material moves forward under the effect of vibration. Its high vibration frequency and small amplitude are suitable for fine and uniform feeding.

Motor Vibrating Feeder

Motor vibrating feeder drives the trough body to carry out sliding and throwing motion through the combined linear excitation force generated by two vibrating motors. The vibration is transmitted to the trough body through the shock absorbing spring to realize the material conveying. Its low vibration frequency and large amplitude make it suitable for feeding large flow and coarse and heavy materials.

Comparison of performance characteristics

Electromagnetic vibrating feeder

- Precise control: support stepless adjustment of feeding speed, can realize instant stop and start, suitable for quantitative feeding and batching.

- Soft feeding: high vibration frequency, small amplitude, small damage to the material, suitable for fragile or fine materials.

- Maintenance Difficulty: Precise structure, high maintenance difficulty, but the failure rate is low.

Motor vibrating feeder

- Large flow feeding: large amplitude, large feeding volume, suitable for coarse and heavy material transportation.

- Easy maintenance: simple structure, easy to replace mechanical parts, low maintenance cost.

- Strong applicability: suitable for harsh working conditions, such as mines, building materials factories, etc.

Comparison of application

Electromagnetic vibrating feeder

- Fine industry: commonly used in food, medicine, chemical industry, etc., for quantitative feeding, batching or with the weighing system.

- Automated production line: suitable for use with packaging machines, weighing equipment, etc., to achieve high-precision feeding.

Motorized Vibrating Feeder

- Heavy industry: widely used in mining, metallurgy, building materials and other industries for conveying coarse and heavy materials such as ore, coal, sand and gravel.

- Large flow scenario: suitable for occasions requiring large flow feeding, such as stone factory, cement factory, etc.

Suggestions for selection

what circumstances is it suitable to choose electromagnetic vibrating feeder?

Scenarios requiring high precision, small amplitude and soft feeding, such as fine chemicals, food processing, pharmaceutical production, etc.

what circumstances is it suitable to choose motor vibrating feeder?

Scenarios that require large flow, large amplitude and strong durability, such as mining, building materials, metallurgy and other industries.

Summarize

Electromagnetic vibrating feeder and motor vibrating feeder have their own unique advantages and application scenarios. Electromagnetic vibrating feeders are characterized by high precision and gentle feeding, which is suitable for fine industries; while motor vibrating feeders are known for large flow and durability, which is suitable for heavy industries. According to your specific needs, choosing the right feeder can significantly improve productivity and reduce operating costs.

If you still have questions about the selection of vibrating feeder, please feel free to contact us, we will provide you with professional technical support and solutions!