Electromagnetic vibrating feeder is a highly efficient material conveying equipment widely used in industrial production. It is driven by an electromagnetic exciter and can evenly, quantitatively and continuously convey materials to the designated location. Compared with traditional mechanical vibrating feeders, electromagnetic vibrating feeders have the advantages of simple structure, convenient maintenance and low energy consumption. This article will deeply analyze the structure, working principle and advantages of electromagnetic vibrating feeders in practical applications.

Core structure of electromagnetic vibrating feeder

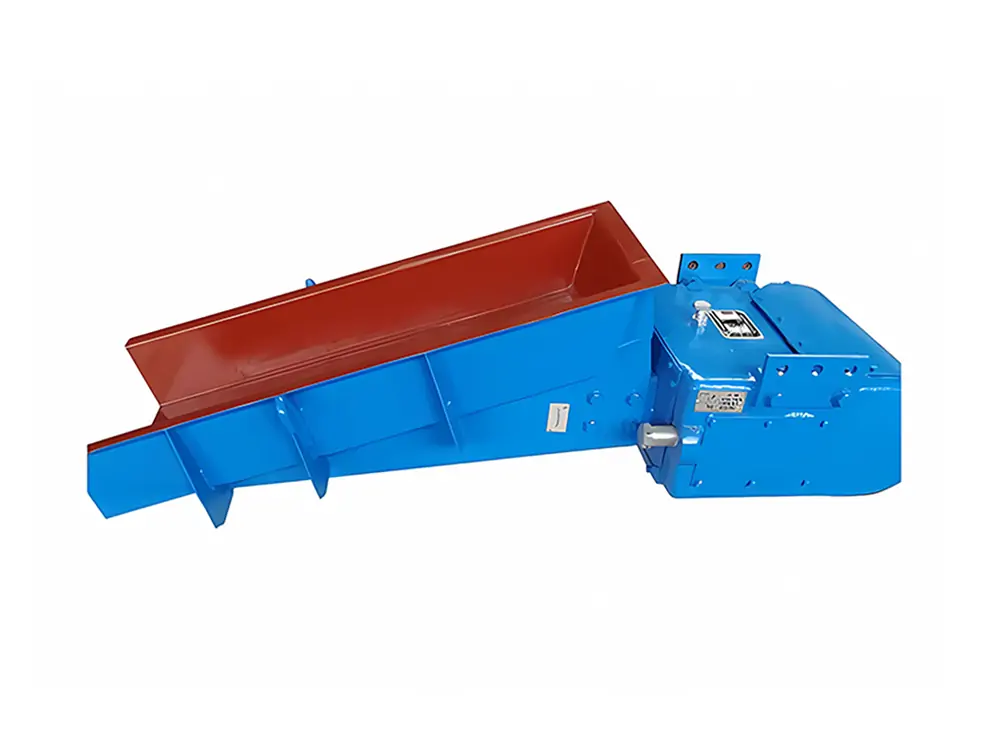

The main structure of electromagnetic vibrating feeder includes two parts: feeding trough and electromagnetic exciter. Unlike motor-driven vibrating feeders, electromagnetic vibrating feeders use electromagnets as power sources, which reduces the number of moving parts, thereby reducing the failure rate and maintenance cost of the equipment.

Feeding trough

The feeding trough is the main working part of the electromagnetic vibrating feeder, usually made of wear-resistant materials, which can withstand the impact and friction of materials. The width, length and depth of the trough can be customized according to specific application requirements to meet the conveying requirements of different materials.

Electromagnetic exciter

The electromagnetic exciter is the core driving component of the equipment. It vibrates the feed trough through the magnetic pulse generated by the electromagnet. This vibration method is not only efficient, but also can accurately control the vibration intensity and frequency, so as to achieve uniform material transportation.

Working principle of electromagnetic vibrating feeder

The working principle of electromagnetic vibrating feeder is based on the magnetic pulse drive of electromagnet. When the electromagnetic exciter is powered on, the electromagnet will generate periodic magnetic force, causing the feed trough to vibrate at high frequency. This vibration is transmitted to the material in a linear manner, causing the material to jump and throw in the trough, thereby achieving continuous material transportation.

Vibration control

The vibration frequency and amplitude of the electromagnetic vibrating feeder can be precisely controlled by adjusting the current size, which can adapt to the transportation needs of different materials, such as granular, powdery or blocky materials.

Material transportation

Under the action of vibration, the material moves forward continuously along the trough, so that the material can be evenly and stably transported to the next process, avoiding the problem of material accumulation or blockage.

Advantages of electromagnetic vibrating feeder

Compared with traditional vibrating feeders, electromagnetic vibrating feeders have the following significant advantages:

High efficiency and energy saving

Electromagnetic vibrating feeders use electromagnetic drive, which has low energy consumption, reduces mechanical wear and prolongs the service life of the equipment.

Precise control

By adjusting the current of the electromagnetic exciter, the vibration frequency and amplitude can be accurately controlled to achieve accurate material transportation.

Low breakage rate

The vibration mode of the electromagnetic vibrating feeder is gentle, which can effectively reduce the breakage rate of materials during transportation. According to statistics, its breakage rate is about 50% lower than that of ordinary vibrating feeders.

Application scenarios of electromagnetic vibrating feeders

Electromagnetic vibrating feeders are suitable for the transportation of a variety of materials, including bulk materials such as coke, quartz, minerals, cement, glass, etc., and are widely used in mining, metallurgy, chemical industry, building materials and other industries.

- Mining industry: used for transporting and feeding materials such as ore and coal.

- Chemical industry: suitable for the precise transportation of powdered or granular chemical raw materials.

- Building materials industry: used for the transportation of building materials such as cement and glass.

- Food industry: used for conveying granular or powdered food.

Summary

Electromagnetic vibrating feeder is an indispensable equipment in modern industrial production with the characteristics of high efficiency, energy saving and precise control. It has a simple core structure, is easy to operate, can significantly reduce the material breakage rate and loss rate, and is widely used in many industries. If you are looking for an efficient and reliable material conveying solution, electromagnetic vibrating feeder is an ideal choice.

Through the introduction of this article, I believe you have a deeper understanding of the structure, working principle and advantages of electromagnetic vibrating feeder. If you have more needs or questions about electromagnetic vibrating feeder, please feel free to contact us!