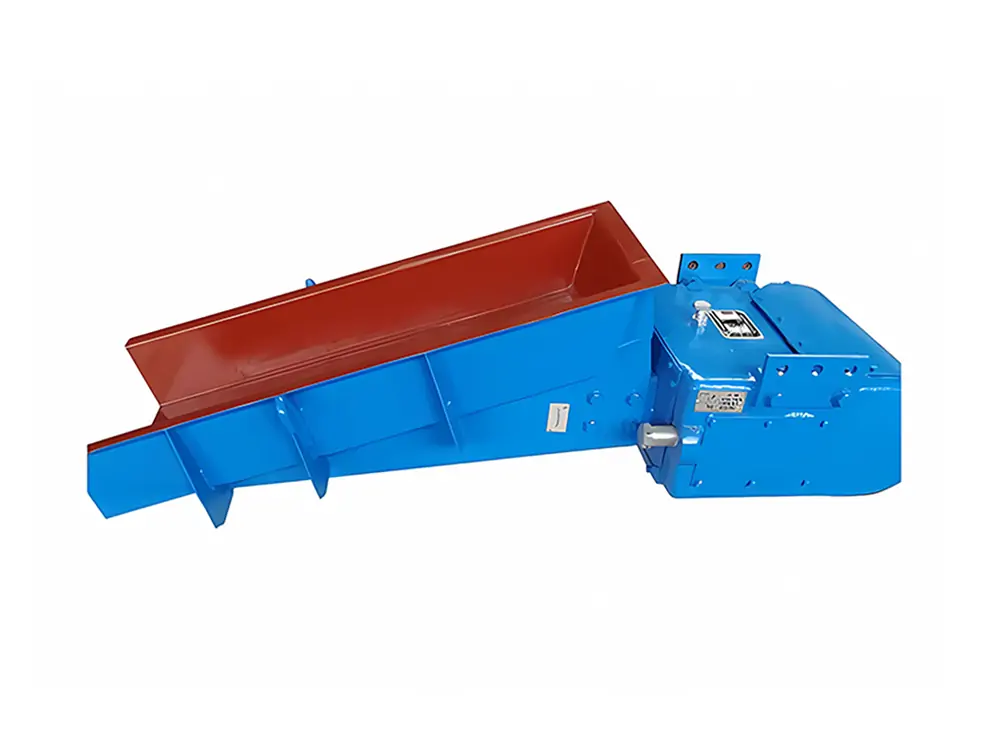

GZG series double motors vibrating feeder conveyor is mainly used to transport block, granular, and powder materials from storage bins or other storage equipment to receiving equipment evenly, continuously, or quantitatively, such as feeding and batching to crushing equipment, screening machine, conveyor feeder, packaging machinery, etc. The equipment has a small size, low noise, lightweight, high energy efficiency, simple installation, and maintenance, and is widely used in automatic batching, quantitative packaging, and automatic control production lines.

- Select type: open, closed, hanging, seated

- Feed size: ≤ 400mm

- Applicable materials: block, granular materials

- Production capacity: horizontal: 30-600t/h downward 10 degrees: 40-1400t/h

- Application areas: metallurgy, coal mining, mineral processing, building materials, chemical industry, abrasives and other industries.

Price: US $425 -$ 2,200 / Set

Double Motors Vibrating Feeder Conveyor Working Principle

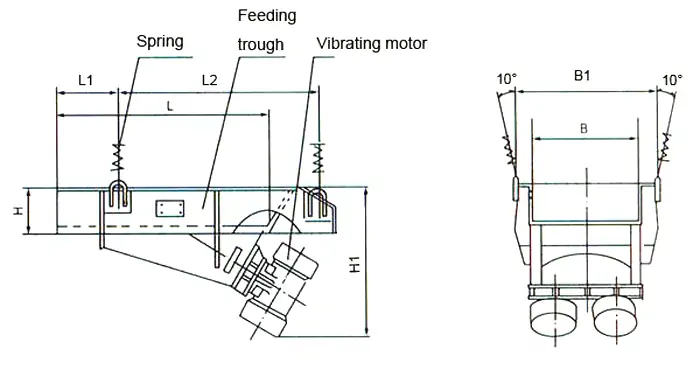

GZG series motor vibrating feeder conveyor drives the exciter through a vibration motor or two motors to make the feeding trough vibrate periodically in a straight line along the inclined direction. When the vertical component of the vibration acceleration of the feeding trough exceeds the gravity acceleration, the material in the trough is thrown up and jumps forward along a parabolic trajectory. The throwing and falling process of the material is completed quickly, and due to the continuous excitation of the excitation source, the feeding trough maintains continuous vibration, and the material in the trough continuously jumps forward, realizing stable transportation and feeding of the material.

Structures

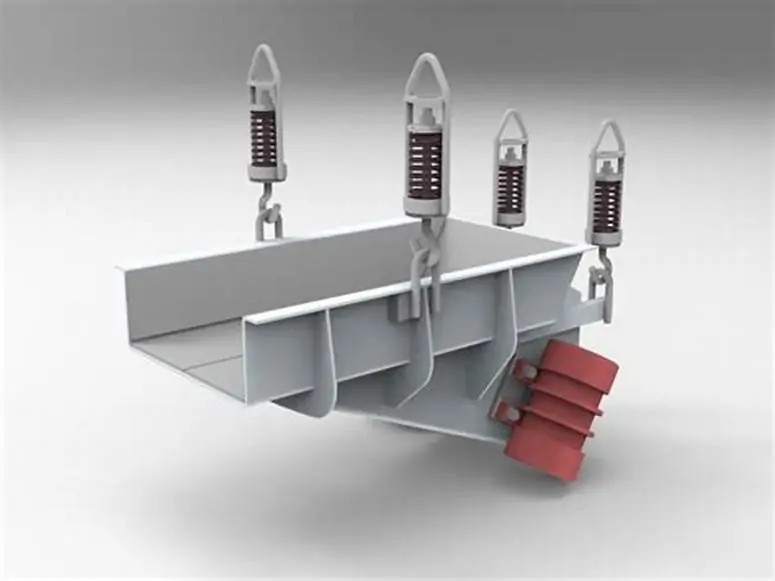

GZG vibrating feeder is mainly composed of feeding trough, exciting motor, motor base, main vibration spring, vibration isolation spring, etc. The following are the functional characteristics of each component:

- Trough: Carrying and conveying materials, directly in contact with materials. The trough body is designed to be smooth, reduce material residue, and facilitate cleaning and maintenance.

- Vibration Motor: Provides vibration force, drives the feeding trough to vibrate, and realizes material transportation. The exciting force is adjustable, the operation is smooth, and the energy consumption is low. It is suitable for dusty environments and has overheating protection function.

- Motor Base: Fixes the exciting motor to ensure stable connection with the feeding trough. It has a vibration reduction effect.

- Main Vibration Spring: Supports the feeding trough and transmits the vibration force of the exciting motor, so that the feeding trough produces directional vibration. It can withstand high-frequency vibration to ensure long-term stable operation of the equipment.

- Vibration Isolation Spring: It has a good vibration isolation effect and reduces the impact of noise and vibration on the surrounding environment. Made of high-quality rubber or spring steel, it is wear-resistant and aging-resistant, and can effectively extend the service life of the equipment.

Details Show

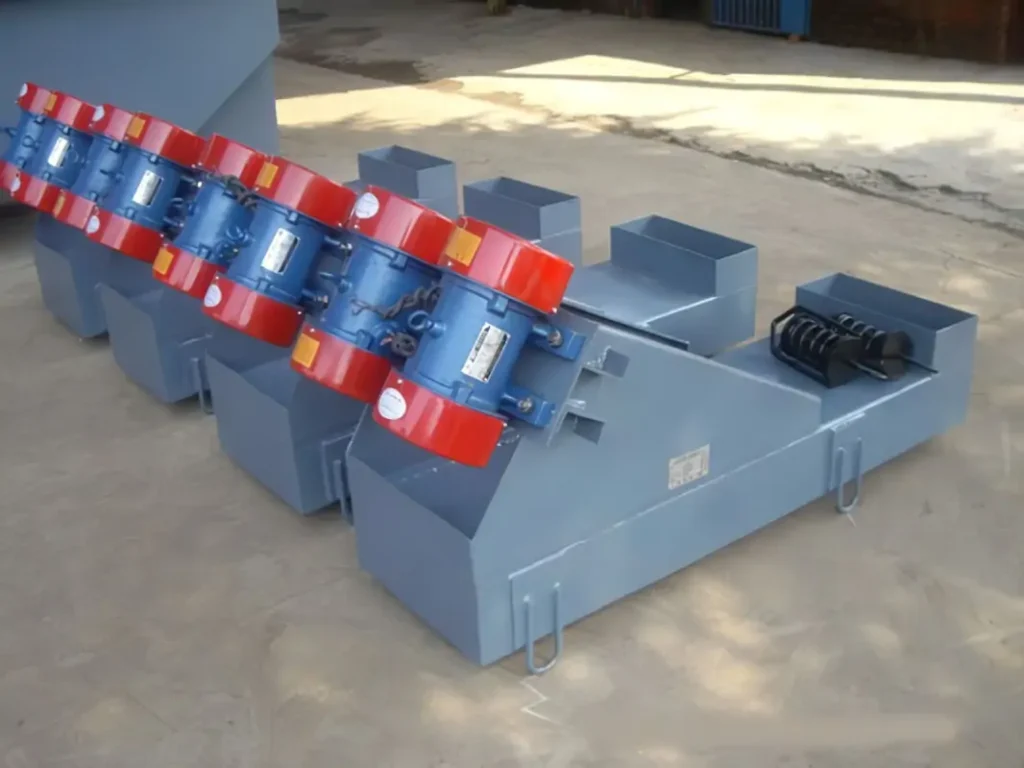

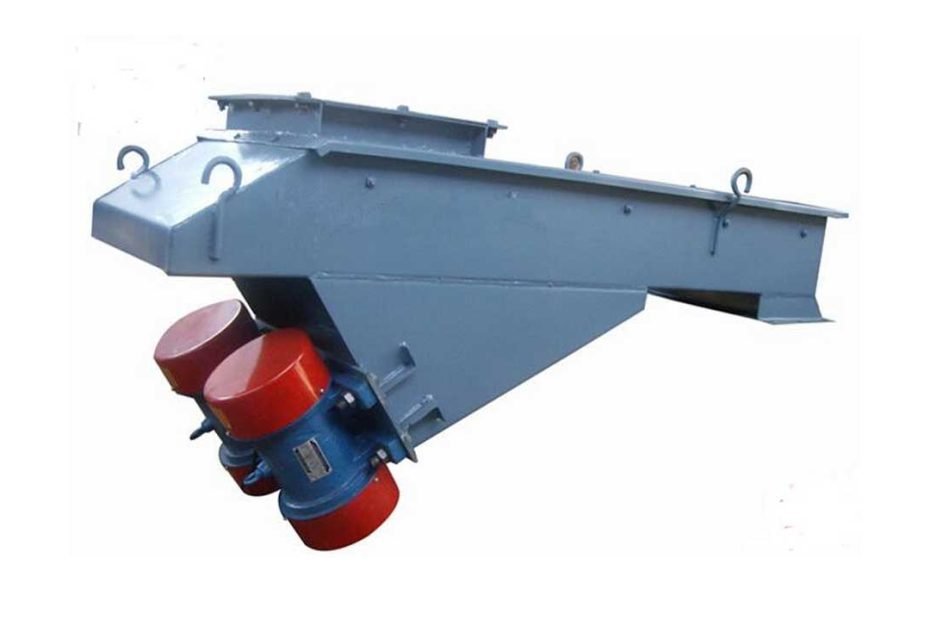

Hanging Vibrating Feeder Conveyor

Feed Port of Vibrating Feeder Conveyor

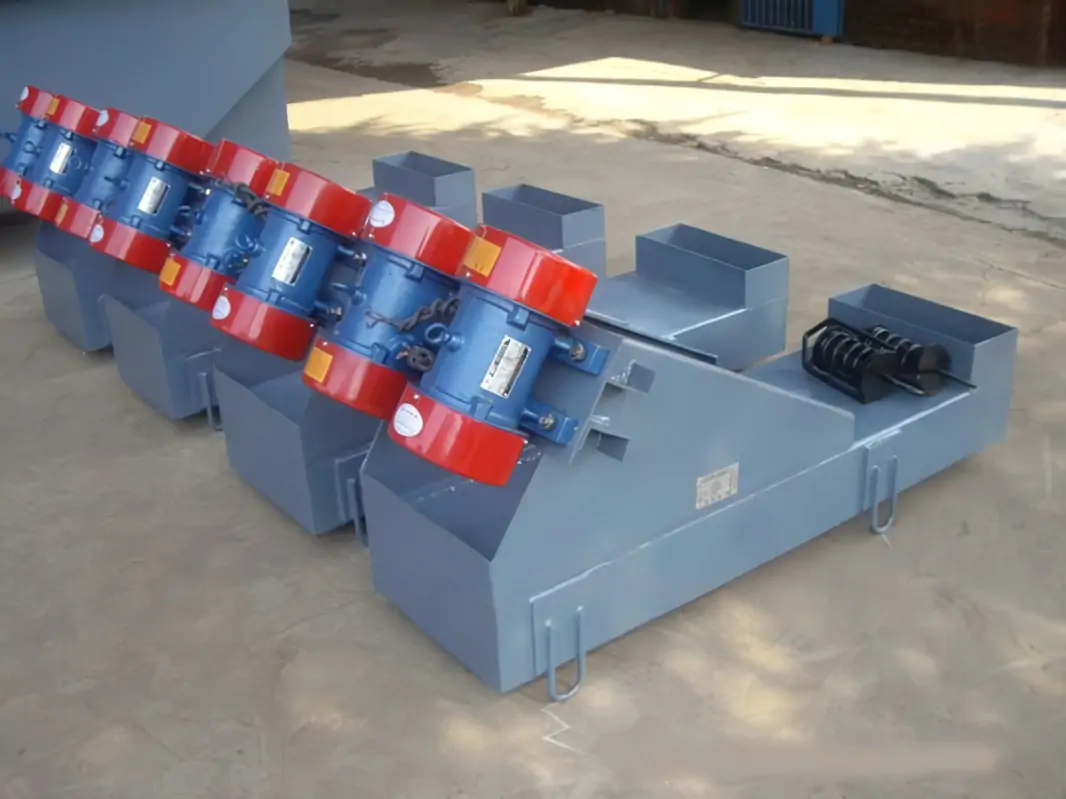

Vibration Motors of Vibrating Feeder Conveyor

Vibration Motors of Vibrating Feeder Conveyor

Specifications

| Model | Feeding Size (mm) | Processing Capacity (t/h) | Model of Vibrating Motor | Power (kW) | RPM (r/min) | Double Amplitude (mm) | Vibrating Force (N) |

|---|---|---|---|---|---|---|---|

| GZG-25 | 60 | 25 | YZO-2.5-4 | 0.25×2 | 1500 | 2-3 | 5000 |

| GZG-30 | 60 | 30 | YZO-2.5-4 | 0.25×2 | 1500 | 2-3 | 5000 |

| GZG-60 | 90 | 60 | YZO-5-4 | 0.4×2 | 1500 | 2-4 | 10000 |

| GZG-80 | 160 | 80 | YZO-5-4 | 0.4×2 | 1500 | 2-4 | 10000 |

| GZG-100 | 210 | 100 | YZO-8-4 | 0.75×2 | 1500 | 2-5 | 16000 |

| GZG-200 | 270 | 200 | YZO-8-4 | 0.75×2 | 1500 | 2-5 | 16000 |

| GZG-300 | 300 | 300 | YZO-17-4 | 0.75×2 | 1500 | 2-5 | 34000 |

| GZG-400 | 300 | 400 | YZO-17-4 | 0.75×2 | 1500 | 3-5 | 34000 |

| GZG-500 | 300 | 500 | YZO-17-4 | 0.75×2 | 1500 | 3-5 | 34000 |

| GZG-750 | 400 | 750 | YZO-30-6 | 2.5×2 | 1000 | 4-6 | 60000 |

| GZG-1200 | 400 | 1200 | YZO-30-6 | 2.5×2 | 1000 | 4-6 | 60000 |

| GZG-1800 | 420 | 1800 | YZO-75-6 | 5.5×2 | 1000 | 5-8 | 150000 |

| GZG-2000 | 420 | 2000 | YZO-75-6 | 5.5×2 | 1000 | 5-8 | 150000 |

Customize Vibrating Feeder Conveyors

Vibrating feeder conveyors are available in a variety of models and designs, including open, closed, hanging and pedestal. We can provide customized solutions based on our customers’ production needs, material characteristics and installation space. Please feel free to contact us, we will provide you with professional technical support and personalized advice.

Open vibrating feeder

Open vibrating feeder Closed vibrating feeder

Closed vibrating feeder Pedestal Vibrating Feeder Conveyors

Pedestal Vibrating Feeder Conveyors

Open vibrating feeder: This design is open at the top and is suitable for bottom vibration applications. It is usually used to convey larger particles or block materials, such as small ores, sand and gravel. The open structure makes the material flow smoother and reduces the friction between the material and the equipment. It is suitable for fast and efficient transportation of bulk materials.

Closed vibrating feeder: This design is completely sealed except for the inlet and outlet. It is suitable for handling fragile particles, dusty or volatile materials, such as chemical raw materials or active ingredients in the pharmaceutical industry. The closed design can effectively prevent dust leakage and ensure the cleanliness and safety of the operating environment. It is particularly suitable for production environments that require strict control of material leakage or prevention of pollution.

Hanging vibrating feeder: This type of vibrating feeder is suitable for production lines that need to save ground space. It is installed in the air by hanging, which effectively reduces the ground area occupied by the equipment. It is suitable for high-level installation and space-constrained environments.

Pedestal vibrating feeder: The pedestal design has stronger stability and is suitable for production environments with high requirements for equipment stability. This design is easy to install on the basic platform, ensures the smoothness of vibration transmission, and reduces the impact of vibration on the surrounding environment.

features

- The product is small in size, low in noise, light in weight, low in power consumption, and easy to install and maintain.

- High feeding efficiency. It can be installed horizontally or tilted, the feeding particle size is 120~360mm, and the output can reach 40~600 tons/hour.

- The feeding and discharging of the material trough can also be made into single-point/multi-point feeding, single-point/multi-point discharging and other forms according to needs.

- The exciting force can be adjusted to change and control the flow rate without material rushing.

- The machine can be equipped with a reverse brake control box to quickly stop the feeder in a short time.

Application

- In chemical production, motor vibrating feeders are widely used to continuously and stably supply powders, granules and other bulk materials, and can work with equipment such as mixers and reactors.

- In foundries and metal processing plants, motor vibrating feeders are used to convey raw materials such as metal scrap, castings, and metal powders.

- In the ceramic and glass industry, motor vibrating feeders can be used to accurately convey raw materials such as powders and granules during the ceramic and glass manufacturing process.

- In the mining and quarrying industry, motor vibrating feeders are used in mines and quarries to accurately and efficiently convey bulk materials such as ore, coal, and aggregates from storage bins to crushers, screens, or other processing equipment.

- At construction sites and aggregate processing plants, motor vibrating feeders are used to convey building materials such as sand, gravel, and concrete.

- In waste recycling and management processes, motor vibrating feeders are used to efficiently convey and separate various types of recyclable materials, such as paper, plastics, and metals.

- In the food and pharmaceutical industries, motor vibrating feeders are used to precisely control the feeding of raw materials, ingredients, and additives.

Conveying Flour

Conveying Flour Conveying Cay

Conveying Cay Conveying Fused Zirconia

Conveying Fused Zirconia Conveying Chemical Powder

Conveying Chemical Powder

Product Show

China Vibrating Feeder conveyor manufacturer and supplier

As a leading manufacturer and supplier of vibrating feeder conveyors in China, Sanyuantang has more than 30 years of industry experience. We are committed to providing customers with efficient and reliable conveying solutions. We have a professional design and R&D team that can customize according to the specific needs of customers, and provide open, closed, suspended, linear and other types of vibrating conveyors to ensure that various working conditions and production requirements are met.

In addition to vibrating conveyors, we can also provide customers with a full range of production line supporting equipment, including vibrating screens, conveyor feeders, mixers, crushers, etc. Our products are widely used in mining, chemical, pharmaceutical, food and other industries, and have been highly praised and trusted by many customers at home and abroad.

We not only follow the “Ease Sieve” design concept, but also always adhere to the principle of quality first, strictly control each production process, ensure that each equipment meets international standards, and provide comprehensive after-sales service and technical support. Whether you are designing a new production line or need to optimize an existing system, we can provide you with professional technical advice and solutions.

Please feel free to contact us, we will provide you with the best quality products and services according to your needs.

FAQs

Related Articles

Related Equipments

In addition to the vibrating feeder converyor, we also provide other processing equipment.