The high frequency filter vibrating screen is a high-quality vibrating screening equipment, mainly used for screening, filtering, drying, dehumidification and other processes of granular materials. Its working principle is to separate the materials into particles of different sizes through the vibrating screen surface, and then classify them according to the particle size.

High-frequency filter vibrating screen has the advantages of high efficiency, high precision, and low noise, and is widely used in chemical, food, pharmaceutical, building materials, metallurgy, mining, and other industries.

Working principle

- Generate high-frequency vibration through vibration excitation: The screen surface of the high-frequency screen is excited by the high-frequency vibration generated by the vibration motor. The vibration motor is connected to the screen box through a connecting rod. By adjusting the speed and axial angle of the vibration motor, the vibration frequency and amplitude can be changed to achieve the screening of the material.

- The stressed material is screened on the screen surface: The screen surface of the high-frequency screen is covered with screen meshes, and the material is evenly placed on the screen surface through the feeding device. Excited by high-frequency vibration, the material moves on the screen surface and is screened through the screen mesh of the screen hole. Smaller particles are screened through the screen holes, while larger particles are blocked above the screen mesh.

- Collection and processing of screening results: Through the movement of the material on the screen surface, the material can be graded according to different particle sizes. Smaller particles are screened through the screen holes, while larger particles are retained above the screen surface. According to the screening results, corresponding processing can be carried out, such as collecting the screened particles or directing the screening results to the next processing unit.

Structures

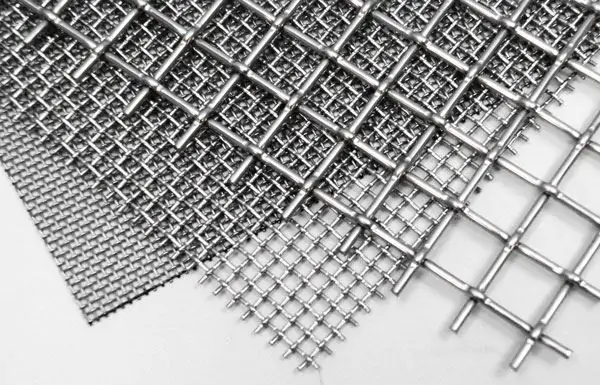

The high-frequency vibrating screen is mainly composed of a vibration generator, screen frame, screen mesh, rebound ball, spring, bracket and other parts. Among them, the vibration generator is the core component of the high-frequency screen, which screens the materials in the screen frame by generating high-frequency vibration. The screen frame and screen mesh are responsible for carrying and filtering materials, while the rebound ball, spring and bracket play the role of shock absorption and support.

Technical Data

| Model | Power Of Motor | Valid Diameter Of Screen | Material | Volume | Weight |

| SYT-600 | 0.35KW | 550mm | 100% SS304 | 610mm*610mm*660mm | 65kg |

| SYT-800 | 0.55KW | 760mm | 100% SS304 | 810mm*810mm*760mm | 78kg |

| SYT-1000 | 0.75KW | 930mm | 100% SS304 | 1010mm*1010mm*860mm | 130kg |

| SYT-1200 | 1.5KW | 1130mm | 100% SS304 | 1210mm*1210mm*960mm | 170kg |

Features

- Compact and Portable Design: The screen’s compactness enables easy transportation and setup, ideal for versatile work environments.

- Precise Screening Efficiency: High-frequency vibration ensures accurate screening of powders, granules, and liquids, enhancing overall efficiency.

- Blockage-Free Mesh Design: The screen prevents mesh blockage, ensuring smooth material flow and minimizing powder dispersion.

- Rapid Vibration Frequency: The screen efficiently separates particles at up to 3,000 vibrations per minute.

- Quick Installation: With a streamlined mesh structure, installation takes only 3 to 5 minutes, enhancing convenience and reducing setup time.

- Effortless Cleaning: The design facilitates thorough cleaning, leaving no residue on the screen surface after operation.

- User-Friendly Maintenance: Easy operation and minimal maintenance requirements contribute to the screen’s reliability and usability.

- Corrosion-Resistant Construction: Stainless steel 304 contact parts make the screen suitable for various materials, including those in food and pharmaceutical industries, ensuring durability and compliance with hygiene standards.

Application

- Chemical Processing: In chemical plants, high-frequency filter vibrating screen is used for various processes like classifying, dewatering, and separating solid materials from liquid streams. They help ensure product quality and reduce waste in chemical production.

- Pharmaceuticals: In pharmaceutical manufacturing, high-frequency vibrating screen is used to separate and classify different pharmaceutical powders, ensuring consistent product quality.

- Ceramic Industry: High frequency screen is employed in the ceramic industry to separate and classify ceramic materials, ensuring uniform particle size distribution.

- Pulp and Paper Industry: High frequency vibrating screen is used for screening and separating pulp and paper fibers during the papermaking process.