The screen mesh is a crucial component of the vibrating screen, essential for separating and grading materials to produce qualified products. However, frequent breakage of the vibrating screen mesh is a common issue due to high wear and tear. This article explains why the wire mesh for vibrating screen often breaks and provides effective solutions.

Types of Vibrating Screen Mesh Improper Selection

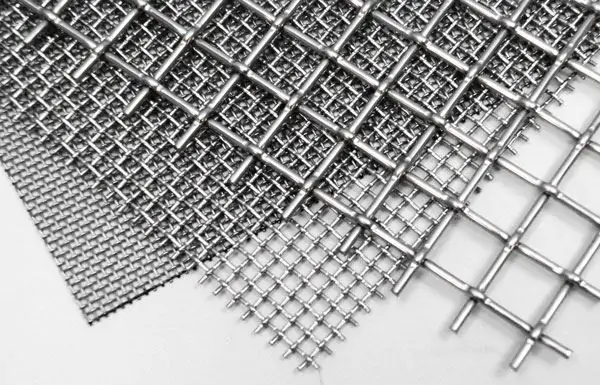

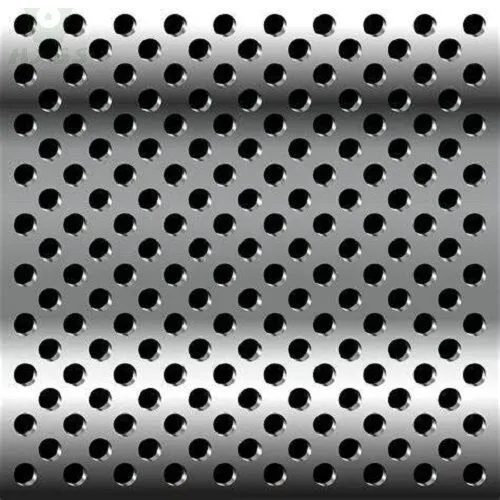

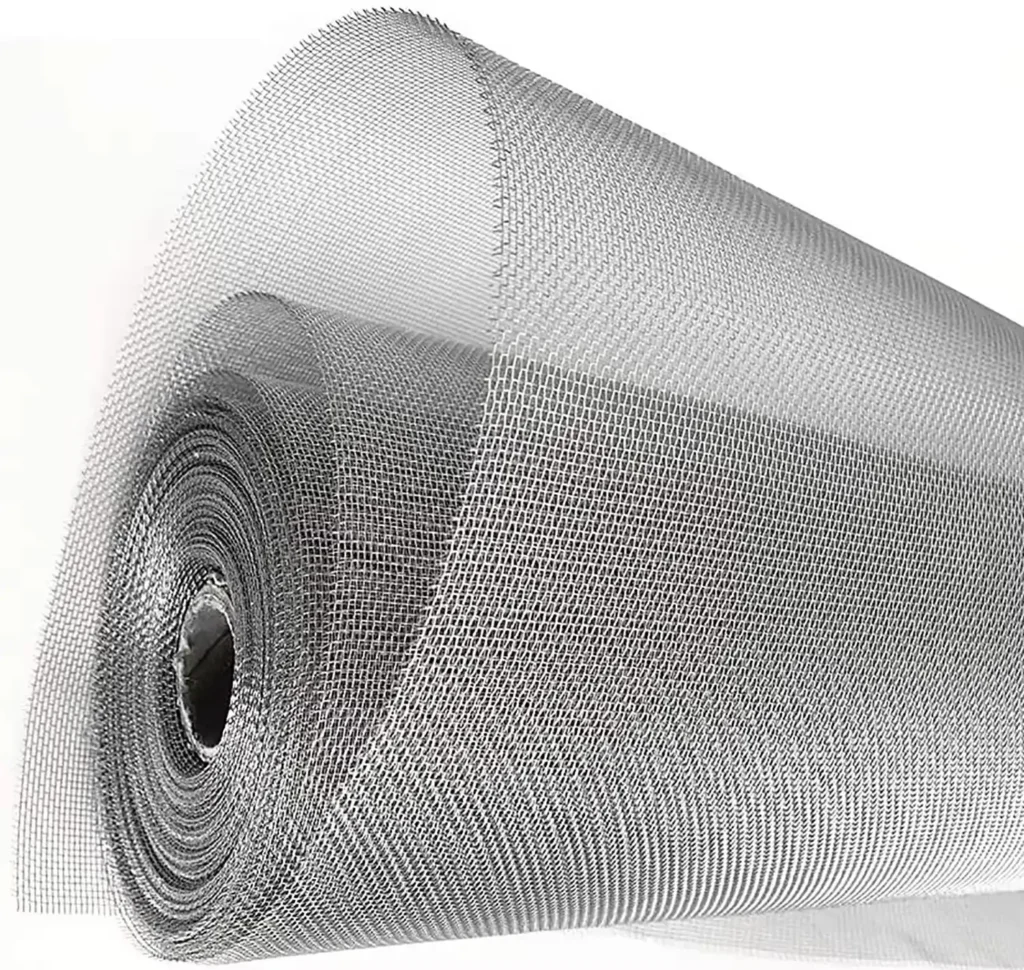

Cause Analysis: There are various types of vibrating screen meshes, including metal wire woven mesh, perforated plate mesh, electroformed mesh, and polyurethane mesh. Selecting an unsuitable type for the material can lead to mesh breakage. For instance, perforated plate mesh is required for materials with high specific gravity, while polyurethane mesh is necessary for irregularly shaped, angular materials. Metal woven mesh and electroformed mesh are suitable for screening lighter materials.

Stainless Steel Woven Mesh

Stainless Steel Woven Mesh Stainless Steel Perforated Sheet

Stainless Steel Perforated Sheet Wire Braided Mesh

Wire Braided Mesh

Solution: Select the appropriate type of vibrating screen mesh based on the specific gravity and shape of the material to ensure durability and effectiveness.

Inappropriate Vibrating Screen Mesh Material Selection

Cause Analysis: Common materials for vibrating screen meshes include 304 stainless steel, carbon steel, and polyurethane. 304 stainless steel is more durable than carbon steel, while polyurethane is the most durable but also the most expensive. If the material does not match the screening requirements, it can cause the mesh to break.

Solution: Choose the appropriate vibrating screen mesh material based on the material properties. For example, use 304 stainless steel or polyurethane mesh for materials that require high wear resistance.

Insufficient Tension on the Vibrating Screen Mesh

Cause Analysis: During the screening process, the vibrating screen mesh directly bears the weight of the material. Over time, it may become slack, leading to insufficient tension. A slack mesh can cause secondary vibration between the screen body and the mesh, leading to breakage from mutual impact.

Solution: Regularly check, replace, and adjust the tension of the vibrating screen mesh, keeping it flat to ensure it maintains proper tension during use.

How to replace the Gyratory Vibrating Screen mesh tep by step?

Please view the following video:

Overloading the Vibrating Screen with Material

Cause Analysis: If too much material is loaded onto the screen at once during the screening process, it can accumulate on the mesh surface, increasing the load and potentially collapsing the mesh. Additionally, materials with high moisture content and stickiness can adhere to the mesh, causing clogging and accelerating breakage.

Solution: Control the amount of material loaded each time to avoid accumulation on the mesh surface. Regularly clean the vibrating screen mesh to prevent clogging, especially for materials with high moisture and stickiness.

Conclusions

The issue of screen mesh breakage in vibrating screens can be effectively reduced by selecting the appropriate vibrating screen mesh size, type and material, maintaining proper tension, and controlling the amount of material loaded. Companies should regularly inspect and maintain the vibrating screen mesh, making timely adjustments and replacements to ensure smooth screening processes and enhance production efficiency. This analysis and these suggestions will help users better utilize vibrating screens, reduce mesh breakage rates, and extend the equipment’s lifespan.