Select The Appropriate Mesh Size

Learn how to increase production by optimizing the use of rotary vibrating shaker screens. This article will share 6 effective ways to help you improve screening efficiency, including strategies such as choosing the right screen size, adjusting vibration frequency and amplitude, optimizing feeding methods, adding screen cleaning devices, and regular maintenance, thereby reducing downtime and maintenance costs.

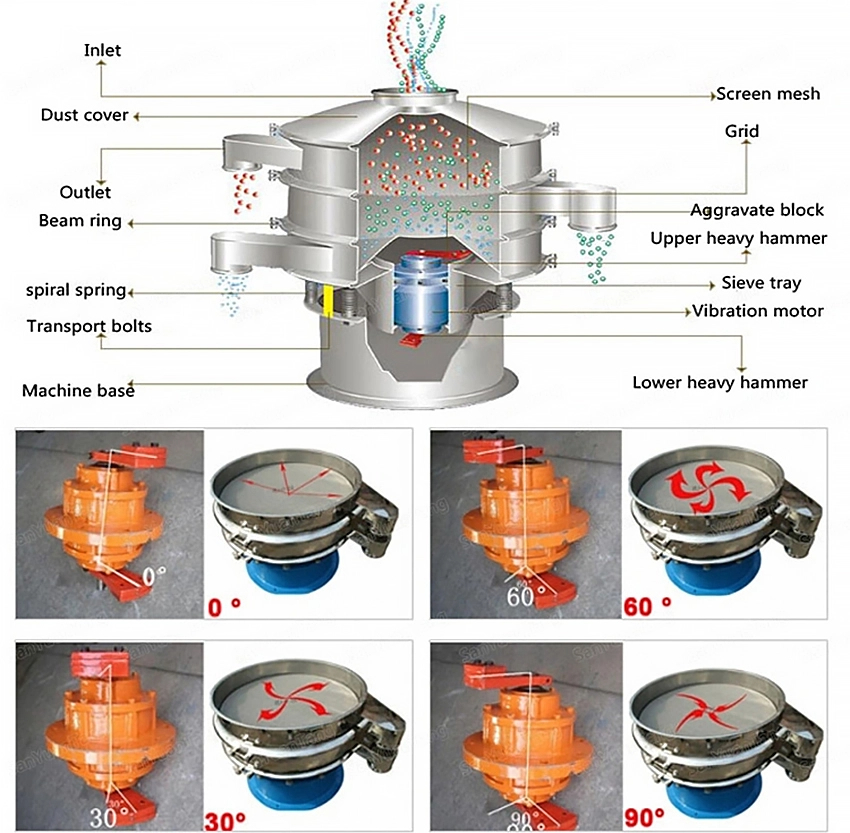

Adjust The Vibration Frequency And Amplitude

The vibration frequency and amplitude directly affect the screening efficiency. Adjust the position of the eccentric block of the vibration motor or replace the vibration motor to change the vibration parameters and improve screening efficiency.

Increase The Number Of Screen Layers

Using multiple screen layers can increase the screening frequency of the material, thereby improving the screening output. Each layer of the screen can perform additional screening, enhancing overall efficiency.

Optimize Feed Quantity And Feeding Method

Control the uniformity and speed of feeding to avoid overfeeding or underfeeding. Use an even feeding device to ensure that the material is evenly distributed on the screen surface.

Regularly Clean And Maintain The Screen

Screen clogging can significantly reduce screening efficiency. Regularly clean the screen to remove clogged particles and maintain the permeability of the screen. Also, check the wear condition of the screen and replace severely worn screens in a timely manner.

Choose The Right Vibrating Screen Model And Configuration

Select the appropriate vibrating screen model based on the material characteristics and output requirements. Different models of vibrating screens have different screening capacities and efficiencies. A reasonable selection can significantly improve screening output.

Use Auxiliary Equipment

Install automatic screen cleaning devices on the screen, such as bouncing balls or ultrasonic cleaning systems, to effectively prevent screen clogging and improve screening efficiency and output.

By implementing these methods, you can effectively increase the screening output of the rotary shaker screen and improve production efficiency.