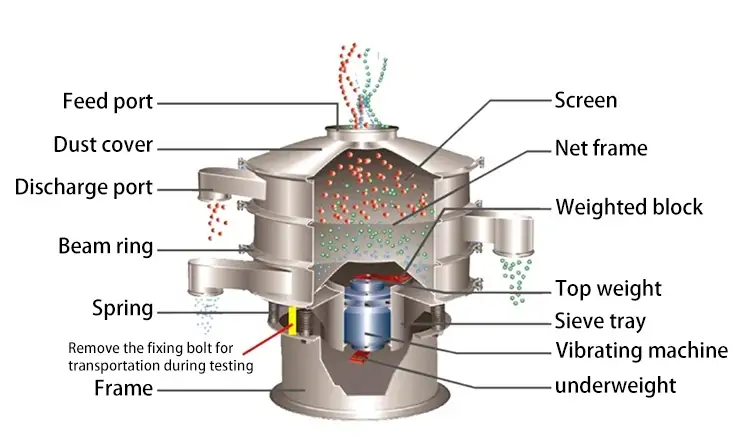

This mini vibrating screen is a compact, high-efficiency small-scale screening device widely used in food processing, small production workshops, and similar applications.

Below, we present a case study from one of our customers in the UAE to demonstrate the performance and operational effectiveness of this equipment.

Mini Vibrating Screen for Sieving Dehydrated Vegetables

This mini vibrating screen machine is made of 304 stainless steel, with a double-layer design and 10 and 12 mesh screens. It is mainly used to separate dehydrated vegetables of different particle sizes. After testing, the screening output of this mini circular vibrating screen can reach 300kg/hour, which completely exceeds the screening demand of 200kg/hour in the UAE.

Equipment details

- Equipment model: SY-400

- Destination country: UAE

- Application: Screening dehydrated vegetables

- Mesh size: 10 mesh, 12 mesh

- Number of layers: 2 layers

Features of mini vibrating screen

- Small size and light weight, low energy consumption, easy to move.

- Equipped with a bouncing ball cleaning device, the screen is not blocked and the screening efficiency is high.

- Unique mother-child mesh frame design, 3-5 fast screen changes.

- 304 stainless steel material, meets food-grade hygiene standard,s and is easy to clean.

- The screen specifications can be replaced for screening and grading of other powder particles.

Mini Vibrating Screen Price

Sanyuantang’s mini vibrating screens typically range in price from $600 to $800, with the actual cost depending on:

- Equipment material (carbon steel, stainless steel, plastic)

- Number of layers (1–5 layers available)

- Whether custom is required

If you’re looking for mini vibrating screens for sale, feel free to contact us for an accurate quote.

Wholesale mini rotary vibrating screen

Sanyuantang Machinery is a manufacturer with 30 years of experience in the R&D, production, and sales of vibrating screens, offering wholesale supply of multiple models of mini rotary vibrating screens.

We provide:

- Complete model range

- Factory-direct pricing

- Minimum order quantity: 1 unit

- Custom solutions available

For quotes or technical inquiries, we will respond within 24 hours to assist you in selecting the ideal screening equipment.

Conclusion

The mini vibrating screen is a compact, precision-screening device meeting food-grade standards, ideal for grading and sorting food materials such as dehydrated vegetables.

If you’re seeking a reliable mini vibrating screen manufacturer or supplier, Sanyuantang Machinery is your optimal partner.

Contact us today for a free quote and custom solutions!