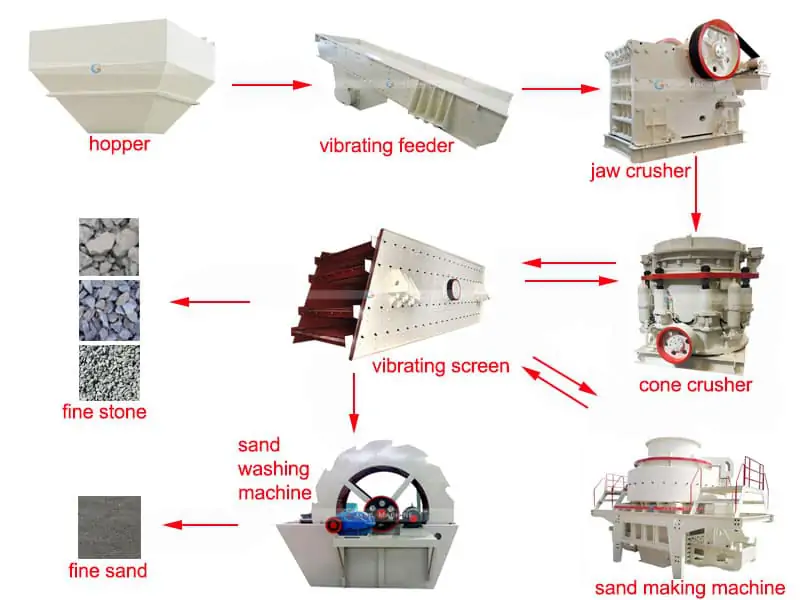

Within the contemporary aggregates industry, demand for sand and gravel production and quality requirements continue to rise. Efficient sand-making production lines can significantly enhance output, reduce energy consumption, and ensure product quality. This article provides a detailed overview of key equipment within sand-making production lines, analyses their functional characteristics, and offers practical recommendations.

So what are the main equipment in the sand production line?

In the sand making industry, there are mainly:

- Crushing equipment

- Sand making equipment

- Screening equipment

- Auxiliary equipment

- Intelligent control system

Then we will analyze and explain the corresponding five equipment according to their uses and optimization suggestions:

Crushing equipment

As the first process of the sand production line, the crusher is responsible for the initial crushing of the raw materials. In the crushing task, it is mainly divided into two types of crushing equipment according to the size of the raw materials: jaw crusher (coarse crushing) and cone crusher/impact crusher (medium and fine crushing).

The working principle of the jaw crusher is to squeeze and crush the material through the periodic movement of two jaw plates. It has the characteristics of simple structure and convenient maintenance; the cone crusher is suitable for medium and fine crushing of high-hardness materials, and the impact crusher is more suitable for medium-hardness materials and can produce better particle shape.

For their optimization

We recommend :

- Regularly check the wear of the jaw plate and plate hammer, and replace them in time to avoid reduced sales;

- According to the different import and export goods, adjust the feeding height and the size of the discharge port to balance the generation and efficiency, and reduce the damage to the machine caused by improper size and height;

- According to product requirements, adjust the parameters of the machine to adapt to the characteristics of different materials.

Sand making equipment

The core equipment of the sand production line is the impact sand making machine and the rod mill sand making machine. The impact sand making machine realizes the fine crushing and shaping of materials through the principle of “stone hitting stone” or “stone hitting iron”, which directly affects the particle shape and quality of the finished sand; while the rod mill sand making machine is suitable for occasions with particularly strict requirements on particle shape, and produces sand materials through the rolling and grinding action of steel rods.

Optimization suggestions for these two types of equipment:

We recommend optimization respectively:

- Impact sand making machine: control its appropriate feed particle size (generally ≤50mm); regularly check the wear of wear-resistant parts; optimize the ratio of impeller speed to material flow; use automatic lubrication system.

- Rod mill sand making machine: maintain appropriate steel rod ratio and filling rate (usually 35%-45%); control appropriate material moisture (generally≤15%); optimize the cylinder speed to 60%-75% of the critical speed.

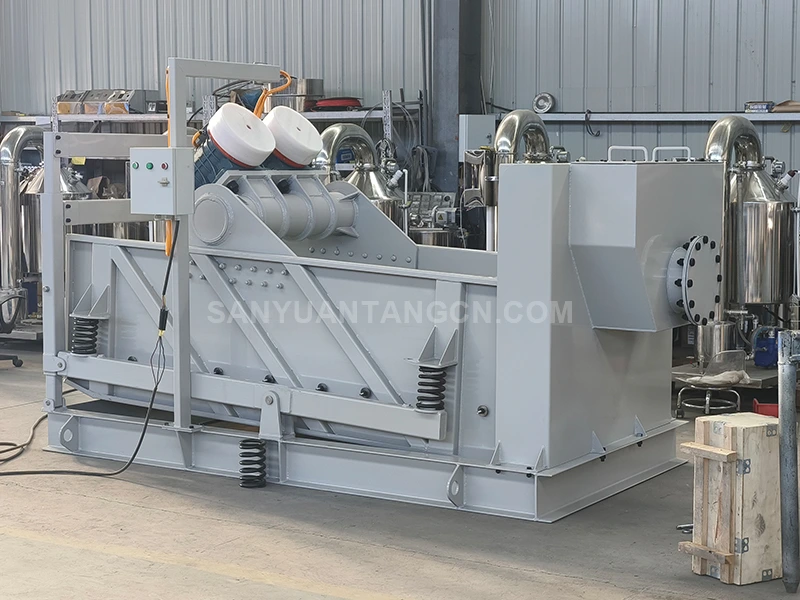

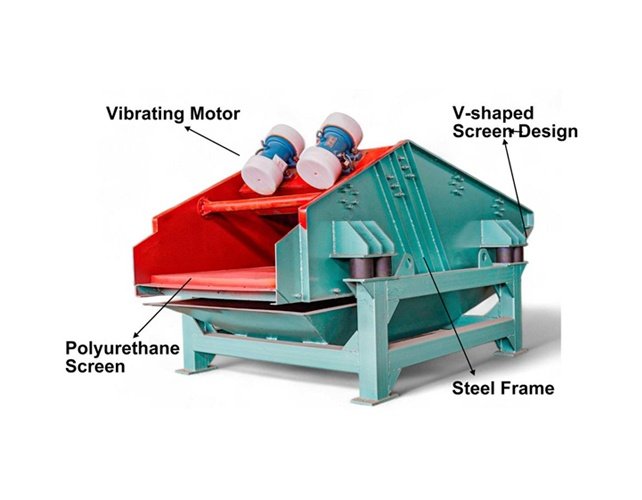

Screening Equipment

The main function of screening equipment is to control the classification of particles so that different particles meet the requirements of use. The main ones used are circular vibrating screens and linear vibrating screens; among them, linear vibrating screens are suitable for fine-particle screening in dry production processes, with large processing capacity and high efficiency.

Optimization suggestions:

- We recommend selecting appropriate screen materials according to material characteristics, optimizing vibration parameters, using multi-layer screen design to improve screening efficiency, and regularly cleaning the screen to prevent clogging;

- At the same time, maintain an appropriate screen surface inclination, balance the relationship between feeding speed and screening efficiency, and use elastic supports to reduce vibration transmission.

If you don’t understand the details of the optimization, you can also contact us and we will give you a more detailed plan.

Auxiliary equipment

Feeder: Stable delivery of raw materials to each device, and attention should be paid to equipment overload or idling;

I suggest the optimization plan: choose a model that matches the host processing capacity, use frequency conversion control to adjust the feed amount, and regularly check the wear of the liner.

Belt Conveyor: mainly responsible for material transmission;

Suggested optimization plan: maintain appropriate tension of the conveyor belt, optimize the transfer point, and regularly check the operation of the roller.

Intelligent control system

In modern sand production lines, intelligent control systems have begun to be widely used. Data from all aspects of the production line are collected in a timely manner, analyzed and decided through intelligent algorithms, and the operating status of each device is accurately controlled. According to data, sand and gravel companies that use intelligent control systems have increased their average production efficiency by 23%, reduced energy consumption by 18%, and reduced equipment failure rates by 35%.

Optimization suggestions: We should establish a complete equipment operation database, arrange online monitoring of key parameters, and establish a remote monitoring and maintenance system.

Conclusion

The above are the core equipment and optimization suggestions required in the sand making process. Because the sand making production line is a production line of different equipment and equipment used in different scenarios, there will be different production requirements. We are a manufacturer with 30 years of experience in vibration screening. We can customize different equipment according to your needs for you to choose. If you happen to have problems with sand production, you can contact us now. We have a professional team to develop a production plan for you to meet your production needs. Contact us now and look forward to cooperating with you.