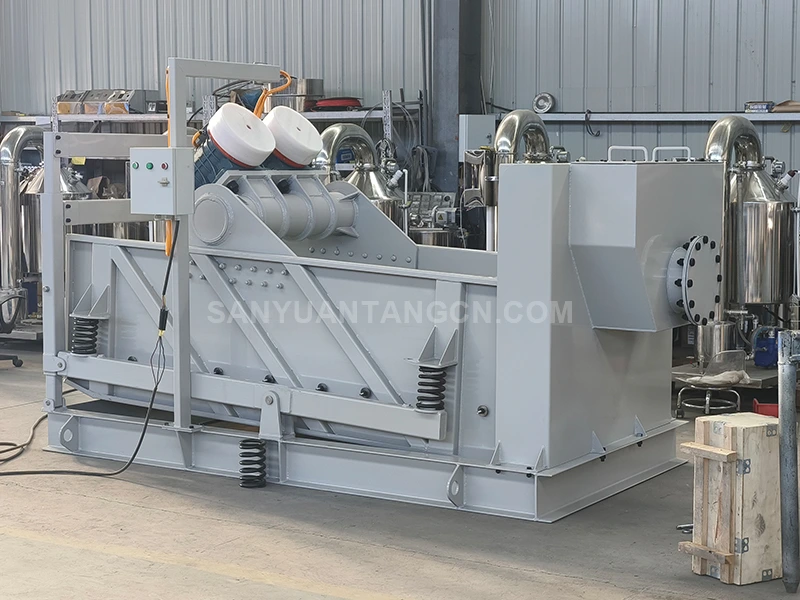

Dewatering vibrating screen is the main equipment for industrial solid-liquid separation, and its performance directly affects production efficiency and product quality. Today, we will explain the key points of efficient and stable operation of dewatering vibrating screen based on the components of dewatering vibrating screen, and provide a reference for equipment selection, maintenance and performance optimization.

Accessories of dewatering vibrating screen

The components of dewatering vibrating screen include screen box structure, vibration motor, shock absorption system and screen assembly, . Below we will introduce the material and working principle of each accessory in detail:

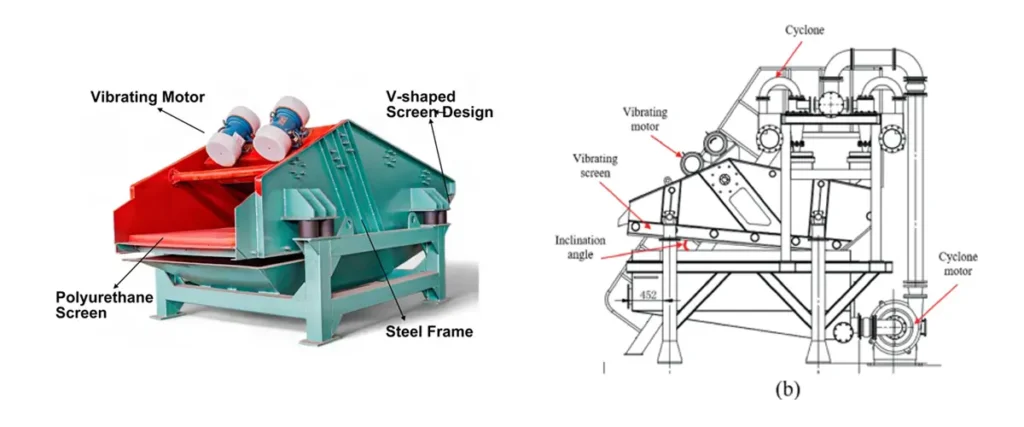

Screen box structure:

The screen box is the main frame of the dehydration operation of the dehydration vibrating screen, which directly affects the processing capacity and dehydration effect of the equipment. In current industrial production, according to different usage scenarios, we usually use carbon steel (Q235B/SS400), stainless steel (304/316L) and polymer composite materials (such as polyurethane lining) as the main materials of the screen box. They can be used in most fields. If you have special needs, you can also contact us. We can make your solution according to your needs.

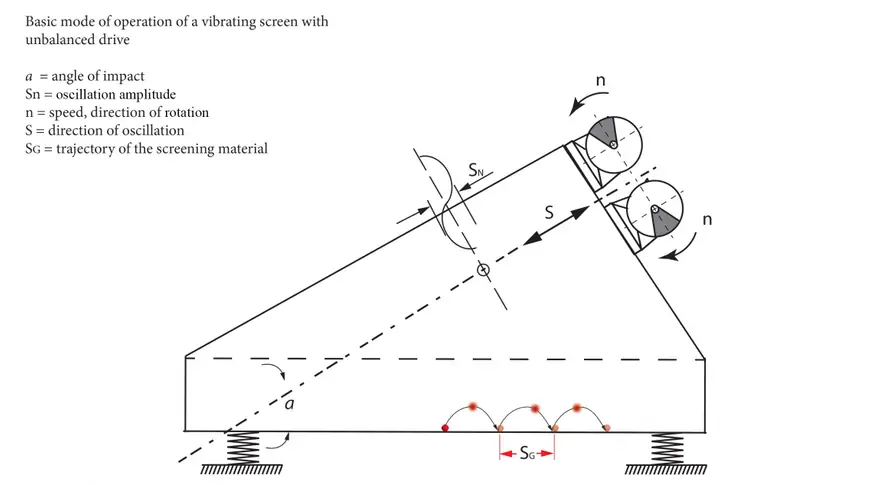

The working principle of the dehydration vibrating screen box is mainly provided by the excitation force of the vibration motor, which makes the material produce a throwing motion on the screen surface, thereby realizing solid-liquid separation.

Common screen boxes are closed: the internal design has a material guide plate, which can effectively prolong the residence time of the material on the screen surface and improve the dehydration efficiency; multi-layer screen box: the material is graded and dehydrated through screens with different apertures to meet the processing needs of materials of different particle sizes.

Vibration motor

The vibration motor provides the required excitation force for the dehydration vibrating screen. Common vibration motors are mainly divided into two types: horizontal vibration motors and vertical vibration motors. The materials are mainly cast iron, stainless steel, cast steel, and high-carbon chromium steel. The material selection mainly considers wear resistance, heat dissipation, corrosion resistance, and mechanical strength. If you don’t know how to choose, you can also contact us. We have a professional team to provide you with a perfect solution.

The working principle of the vibration motor is to generate centrifugal force through the rotation of the eccentric block, so that the screen box produces periodic vibration, so that the material is thrown, layered, and dehydrated.

Shock absorption system

The shock absorption system of the dewatering vibrating screen mainly absorbs the resonance caused by the vibration of the screen box to reduce the vibration of the surrounding equipment. Common materials of the shock absorption system: rubber springs, metal coil springs, composite springs and air springs. Different materials have different effects on the smoothness of equipment operation, noise levels and structural stress conditions. A reasonable shock absorption system can not only increase the life of the equipment, but also improve the screening efficiency.

The shock absorption system of the dewatering vibrating screen reduces the transmission of vibration and the impact on the equipment by isolating the vibration system (screen box) from the foundation through elastic support or energy dissipation mechanism.

Screen assembly

The screen is the core component of the dehydration operation, which determines the accuracy of screening and the quality of the product. Its main materials are stainless steel, wear-resistant alloy steel, polyurethane elastomer, rubber screen and composite screen. In terms of structure, it can be divided into three main types: woven screen, punched screen plate and slotted screen plate. The woven screen has a high opening rate and is suitable for fine dehydration; the punched screen plate has a strong structure and is suitable for large-particle materials; the slotted screen plate is widely used in coal, ore and other industries with its precise gap size.

The working principle of the dehydration vibrating screen is to make the material produce a throwing motion through vibration, and use the aperture screening to separate the solid and liquid. The fine particles and liquid are discharged through the screen, and the coarse particles are transported along the screen surface to the discharge end to complete the dehydration.

Conclusion

Through the understanding of the core components of the dewatering vibrating screen, I believe you have a basic reference when purchasing the dewatering vibrating screen. The dewatering vibrating screen is an indispensable equipment in industrial production. Now more manufacturers are constantly optimizing and upgrading it, and are also moving towards the direction of “high precision, long life, and intelligence”. Finding a suitable, long-term and reliable partner is your first choice. As a technology leader in the field of vibration equipment, our company is committed to providing high-quality screening equipment and solutions to customers around the world. As one of the company’s core products, the dewatering screen has become a benchmark product in the industry with its technological innovation, full-chain quality control and high-quality services.

Choosing Sanyuantang Machinery is not only choosing an efficient screening equipment, but also choosing a craftsman spirit of excellence and a trustworthy partner. Let us work together to inject more Chinese wisdom into the global industrial screening field!